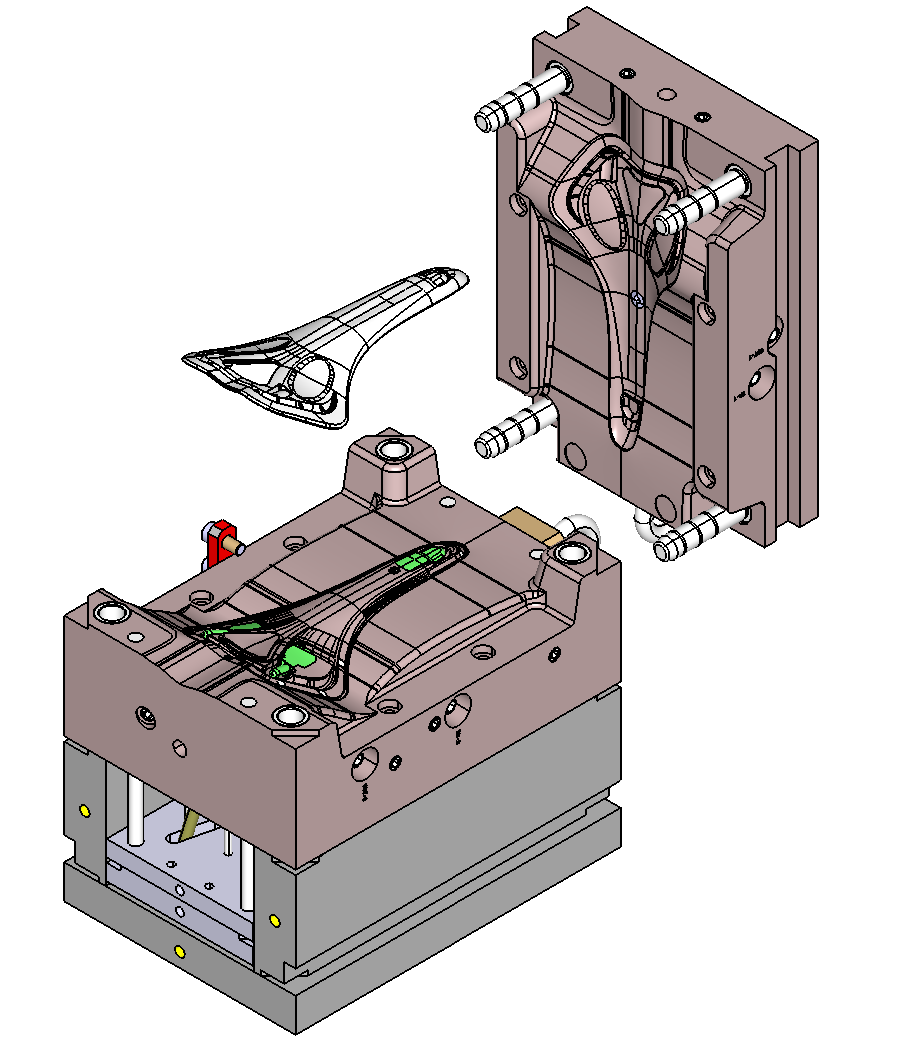

Step 1: DFM ANALYSIS

FEASIBILITY / INDUSTRIALISATION

Design for Manufacturing Analysis or DFM Analysis precedes mould design.

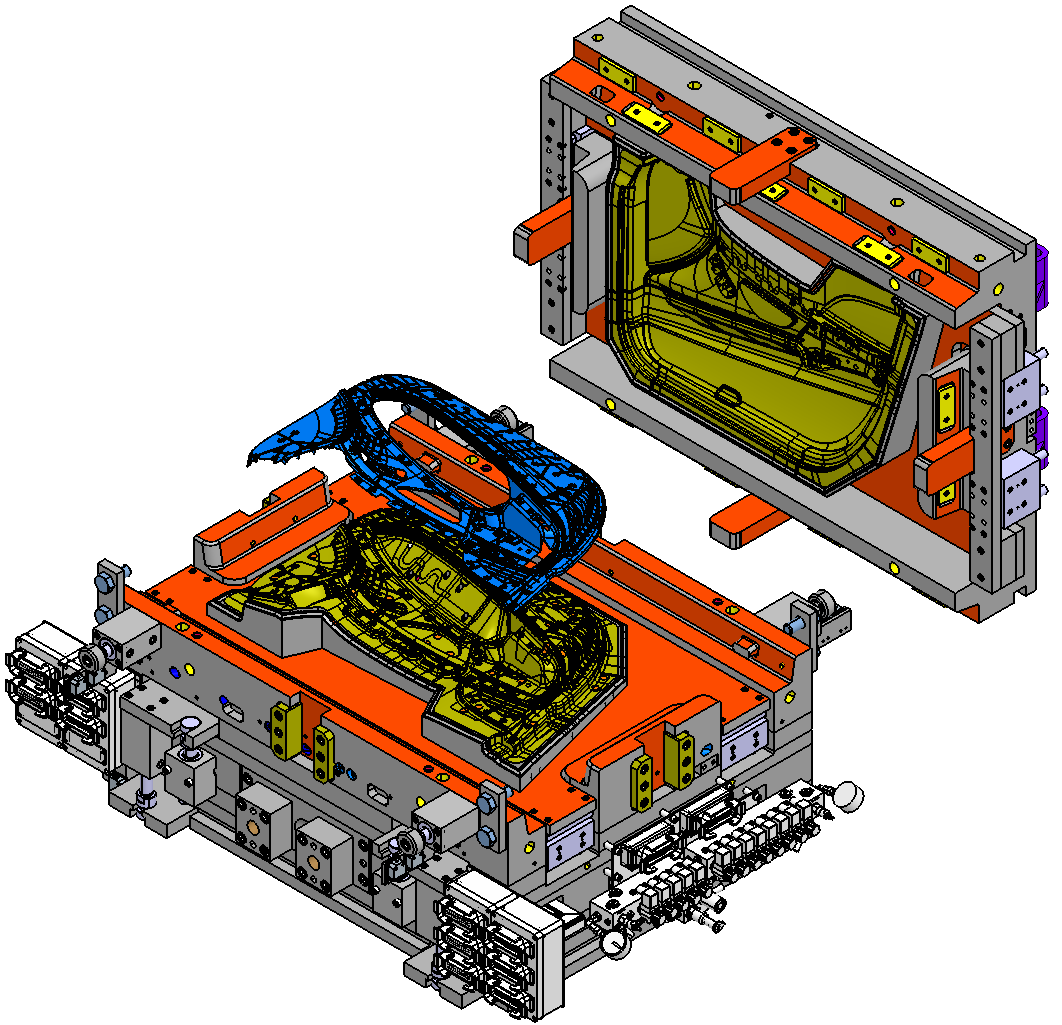

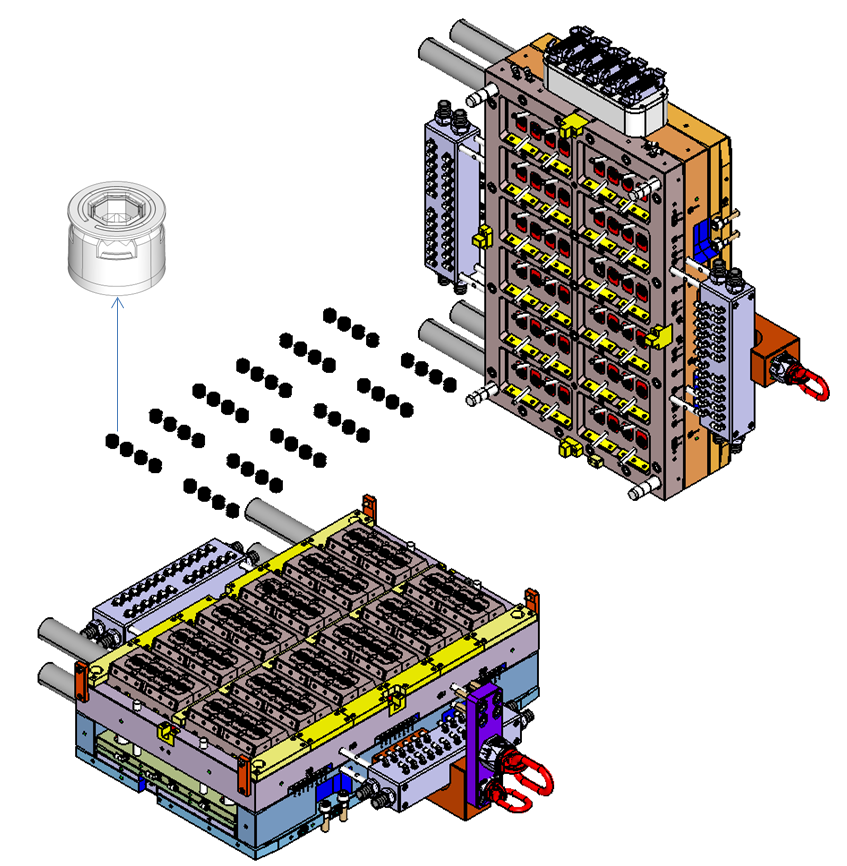

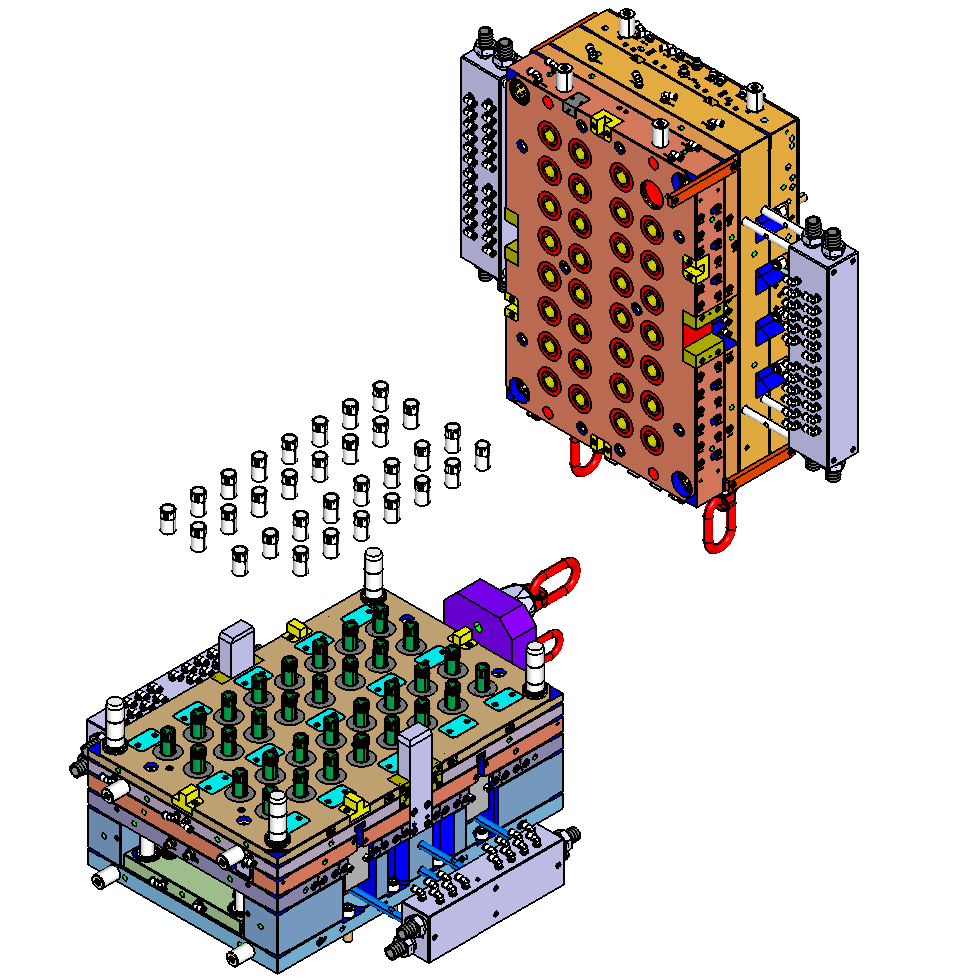

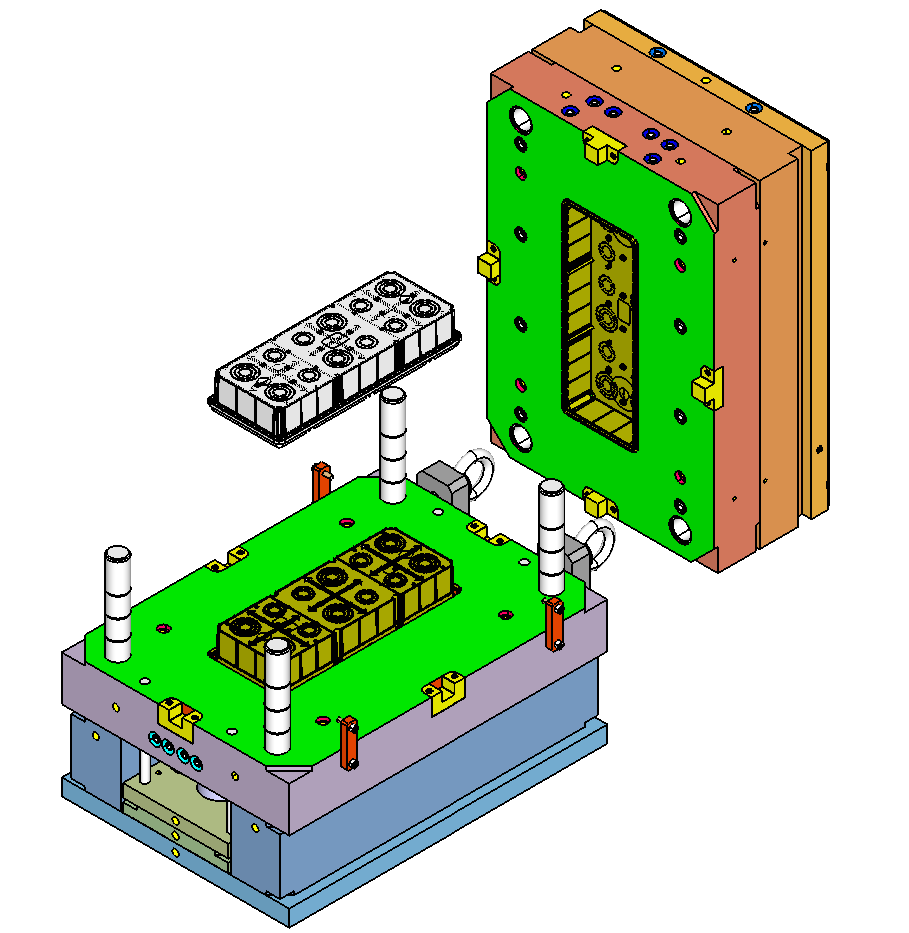

A feasibility study is carried out, carefully evaluating :

- Moulding axis

- Part-line , also considering any signs on the finished product

- Any areas of the part to be obtained from movable parts/inserts in the mould.

- Thicknesses, in order to avoid aesthetic problems of the finished product

- Extraction

- Forms

- Injection point – MoldFlow

The feasibility analyse will be sent to the client

by means of a document called “Concept “.

Any changes are made in the next step of industrialization

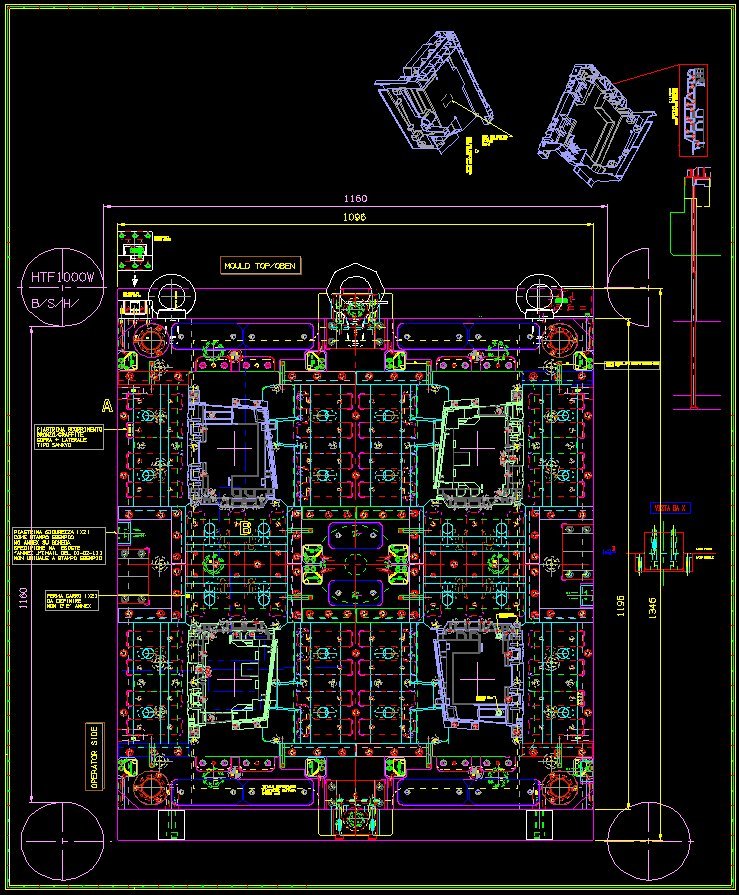

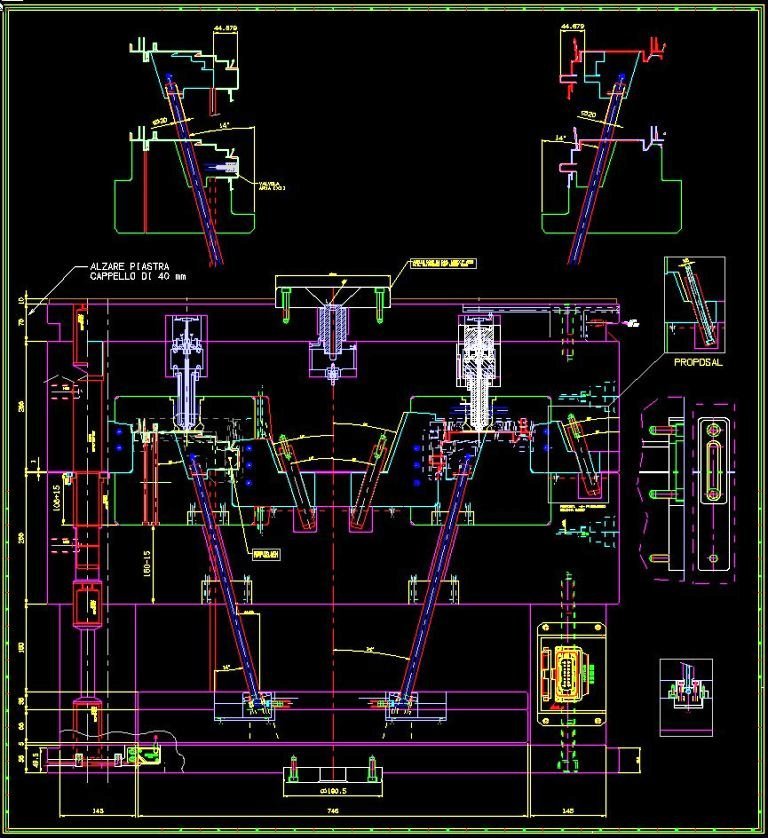

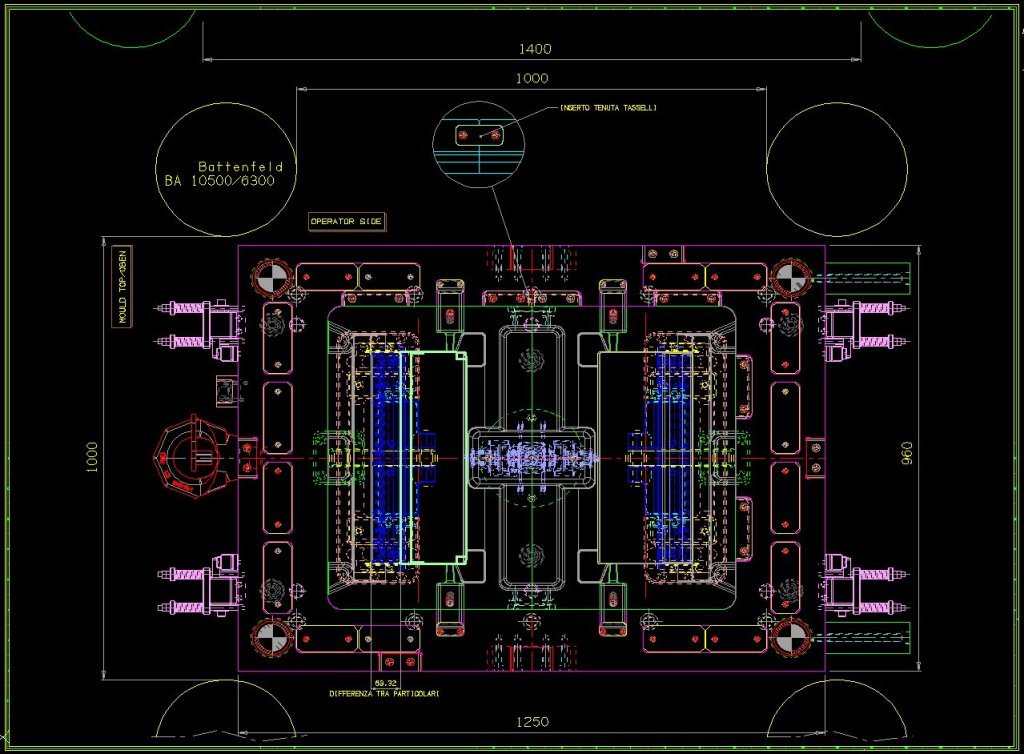

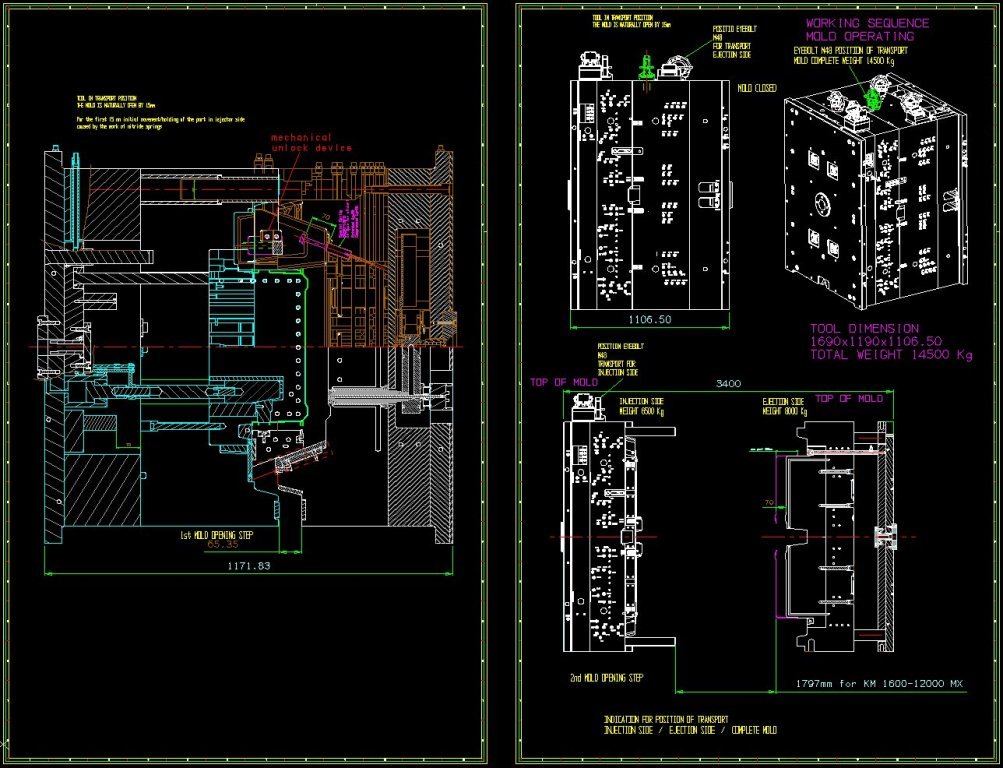

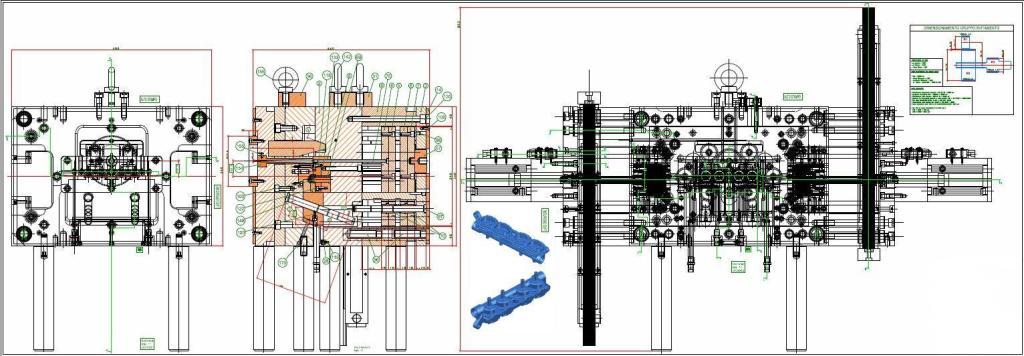

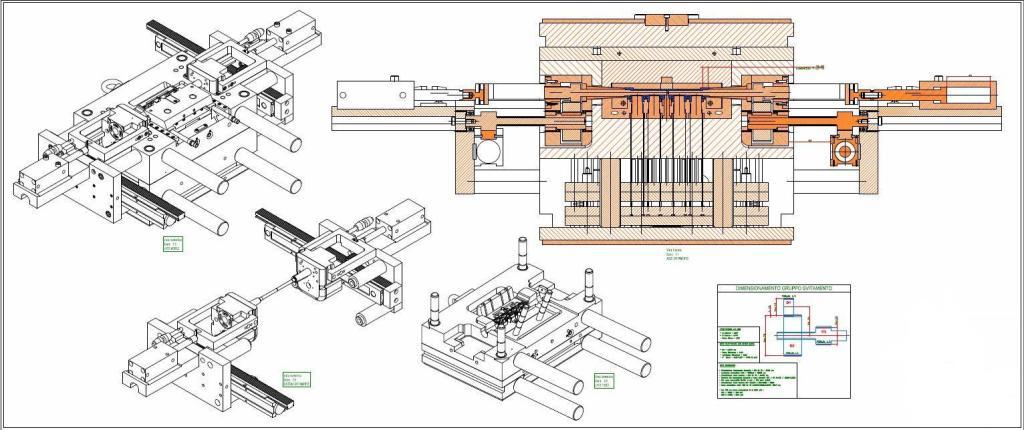

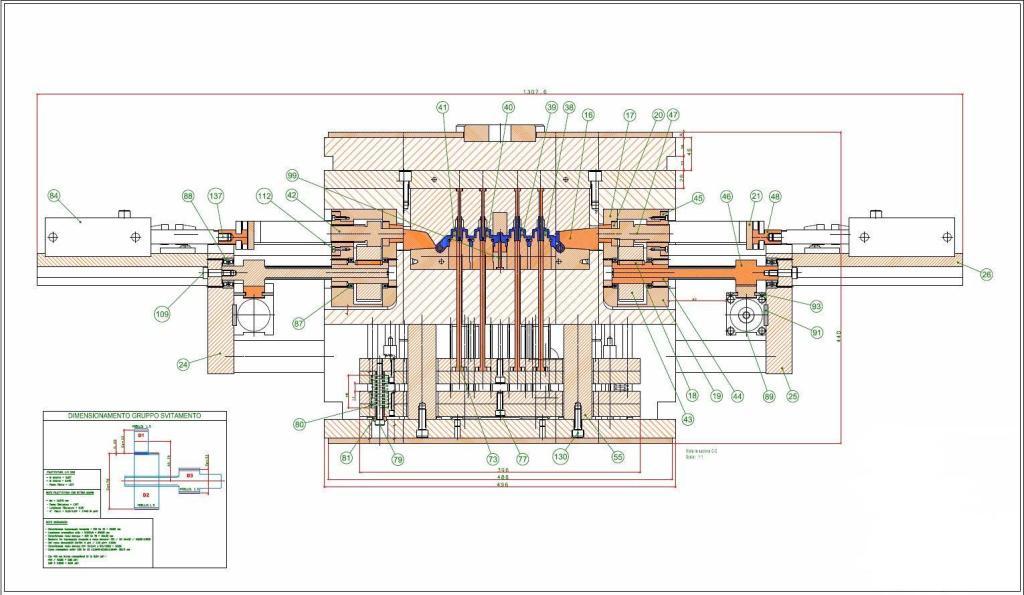

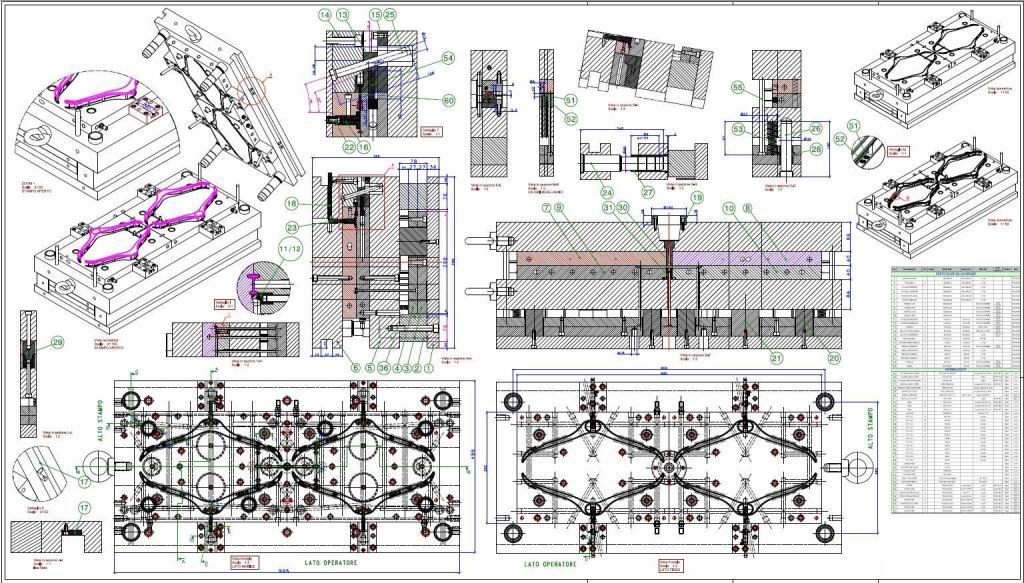

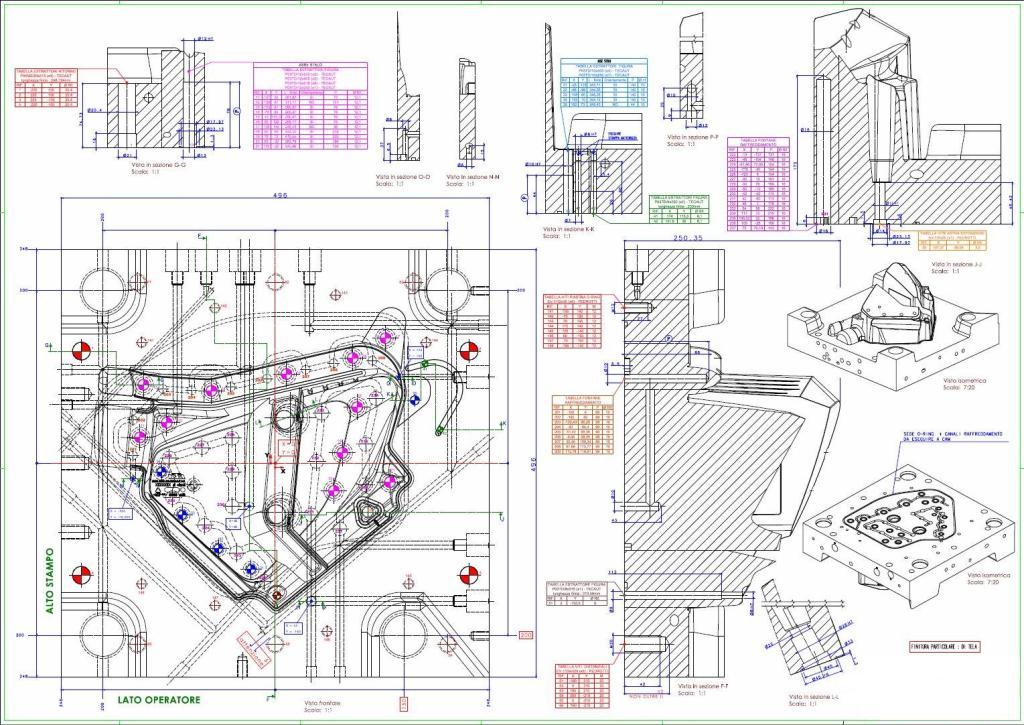

Step 2 INITIAL STUDY ON 2D DRAFTING

SOFTWARE : CADKEY

Firstly, we provide the customer with a 2D- drafting of the mould, made in a very short time, for a preliminary evaluation of the project. Secondly, problems are highlighted and customer will be informed at the same time about the delivery delay of raw materials for the mould construction.

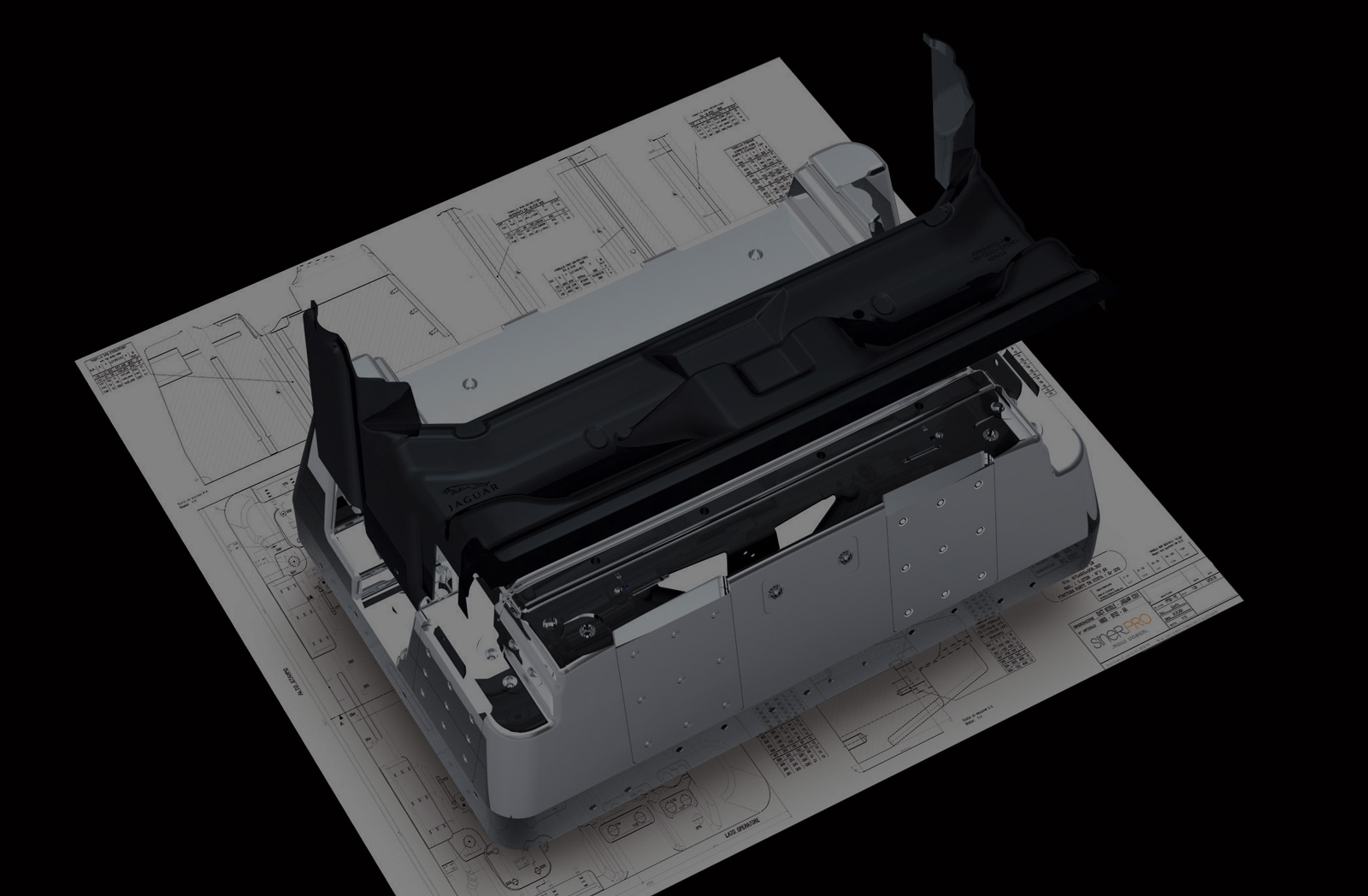

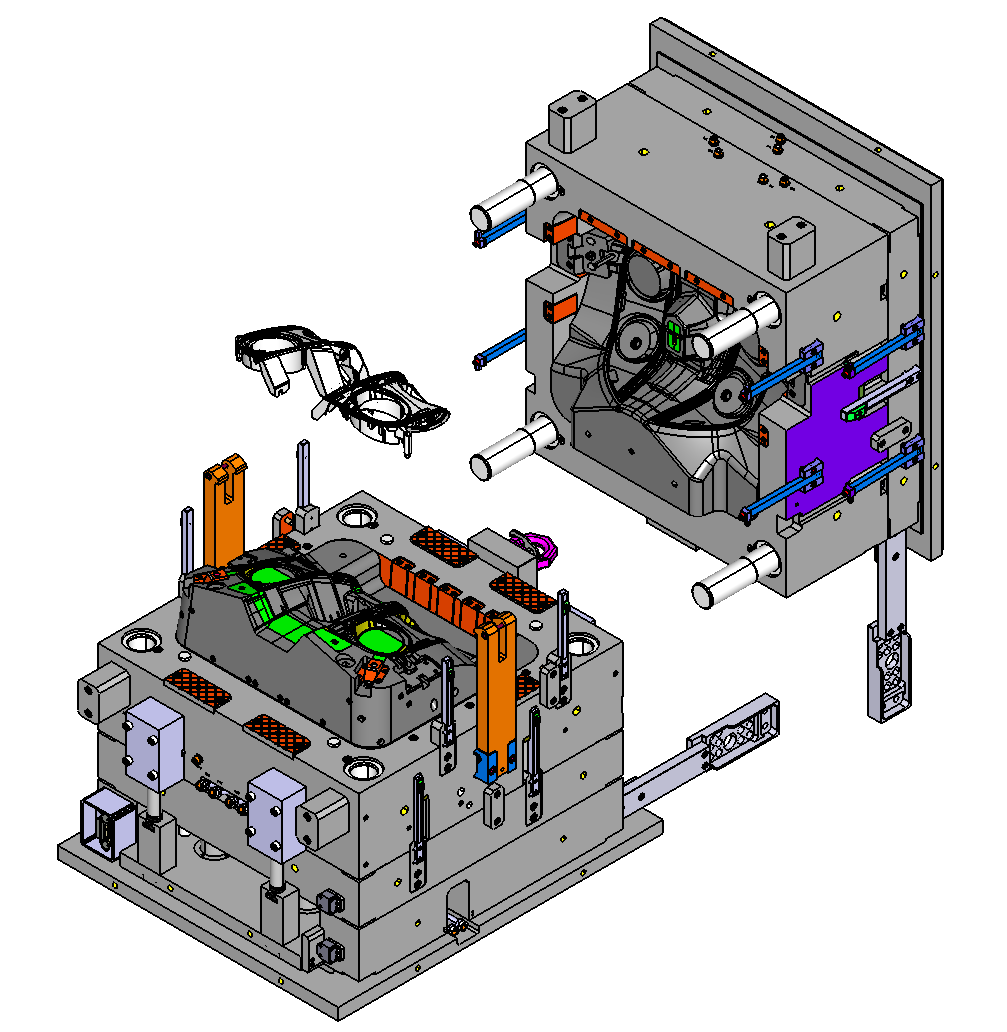

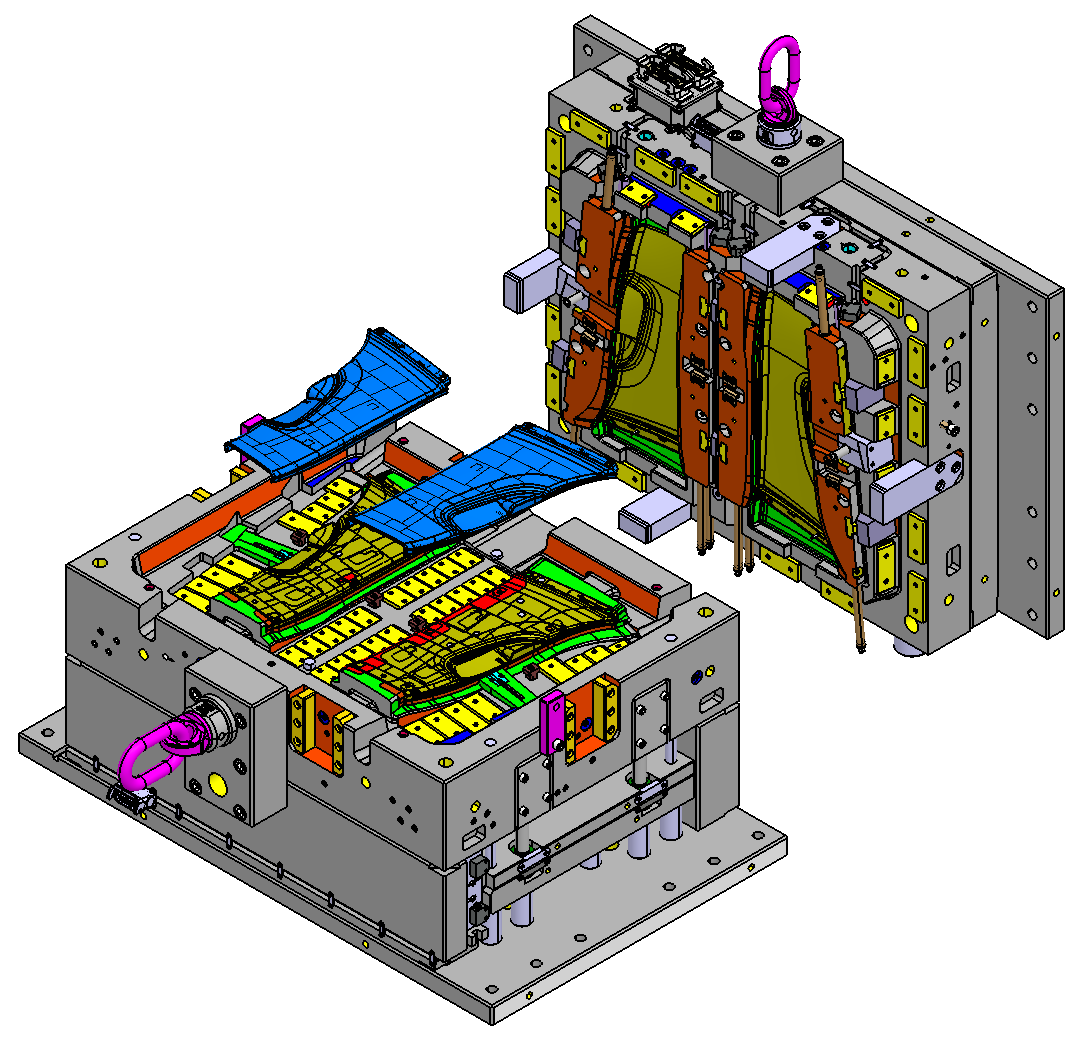

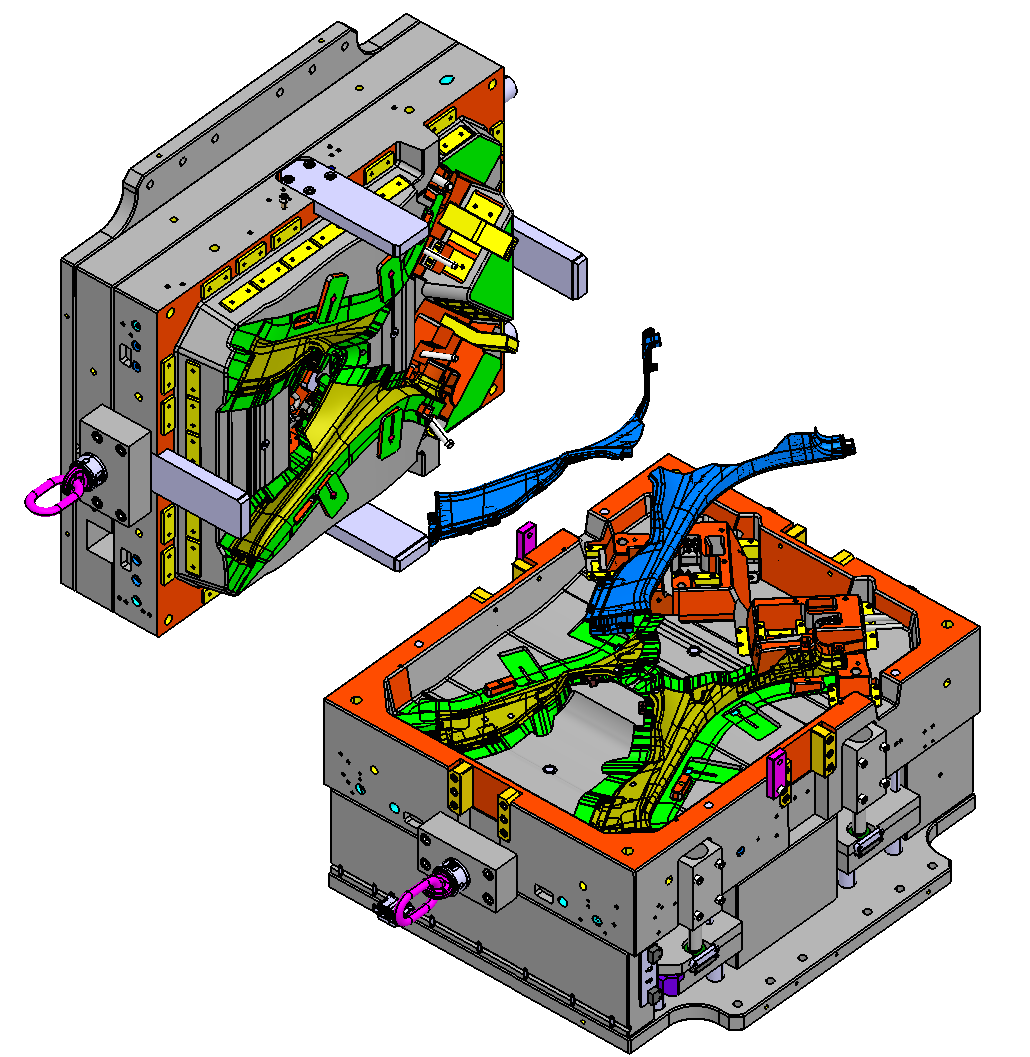

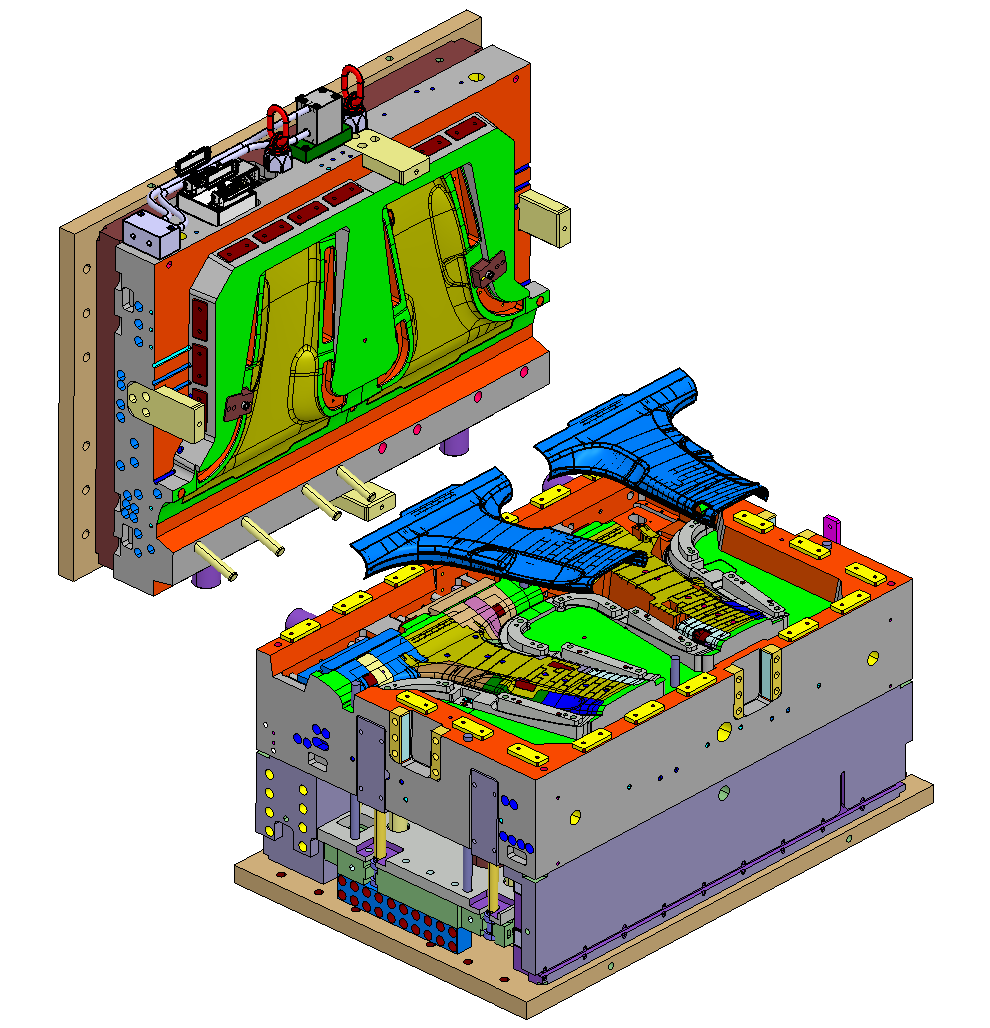

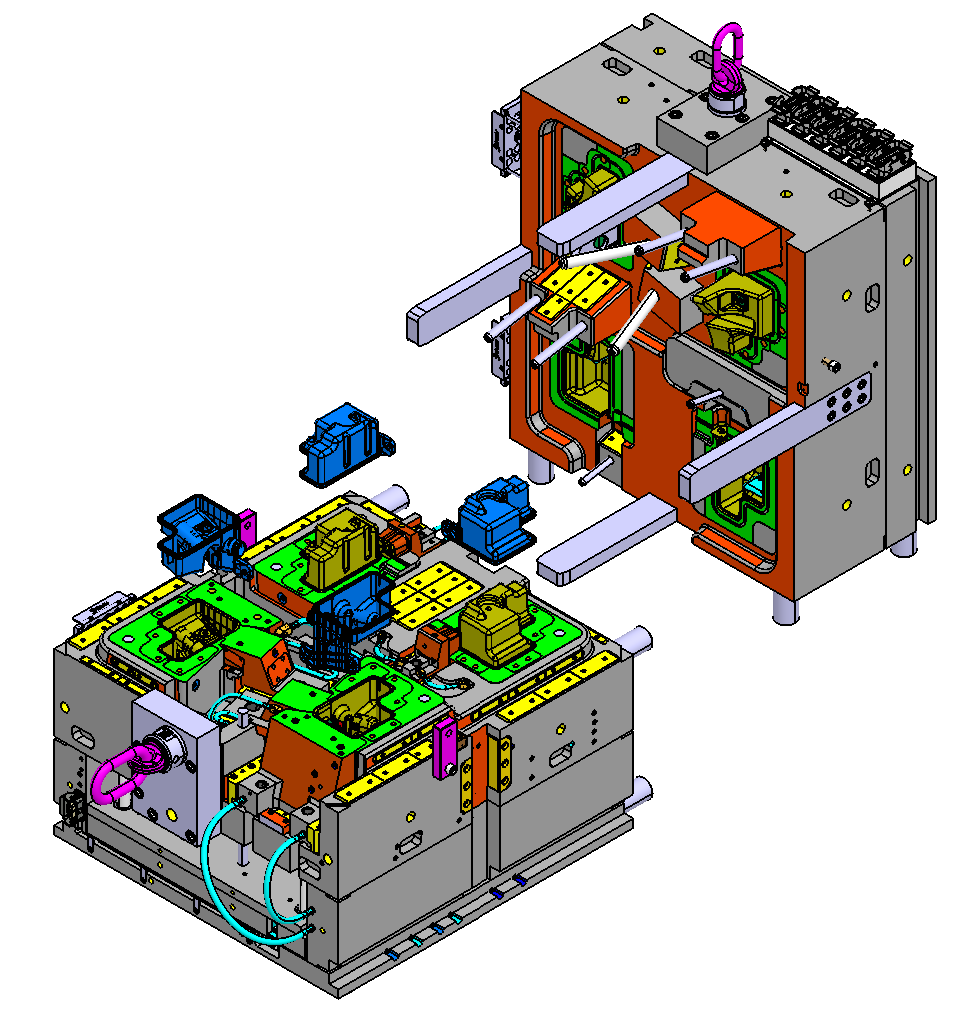

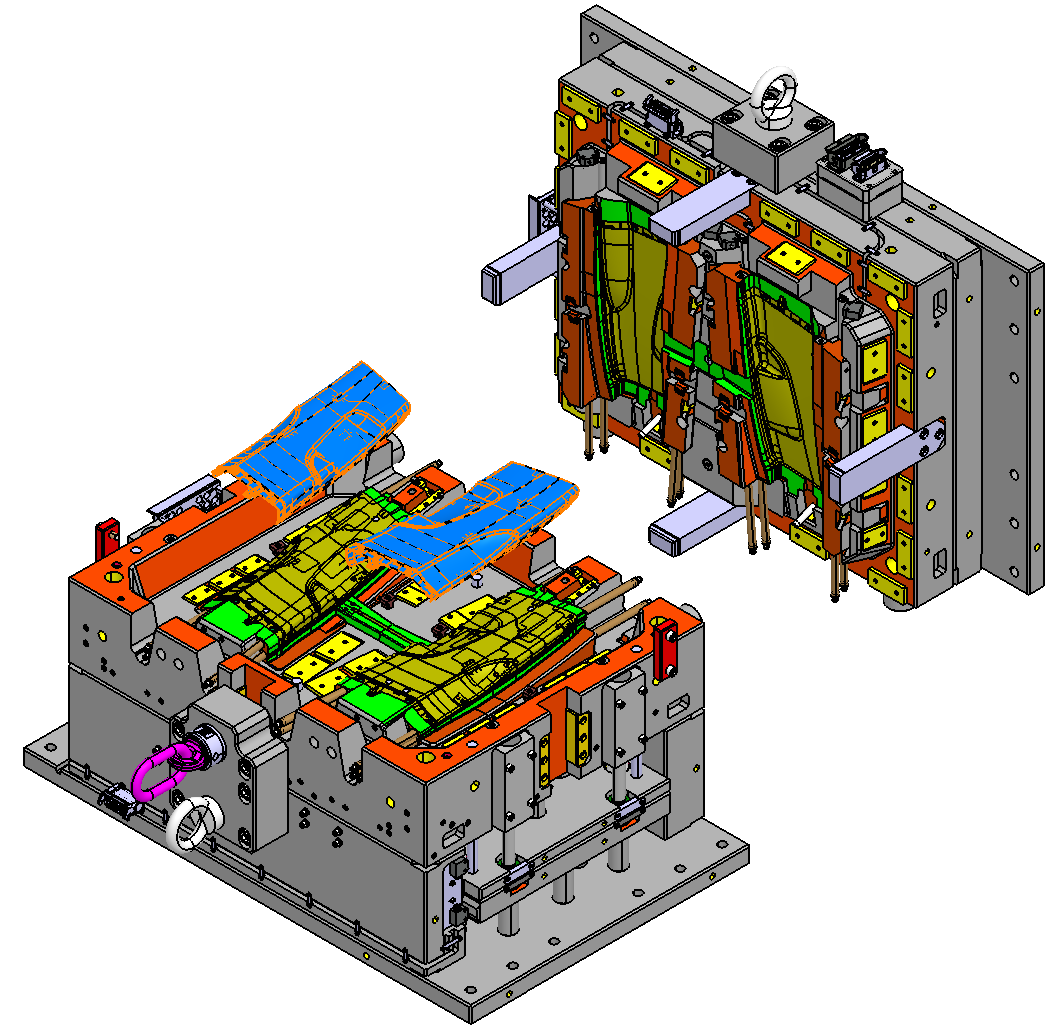

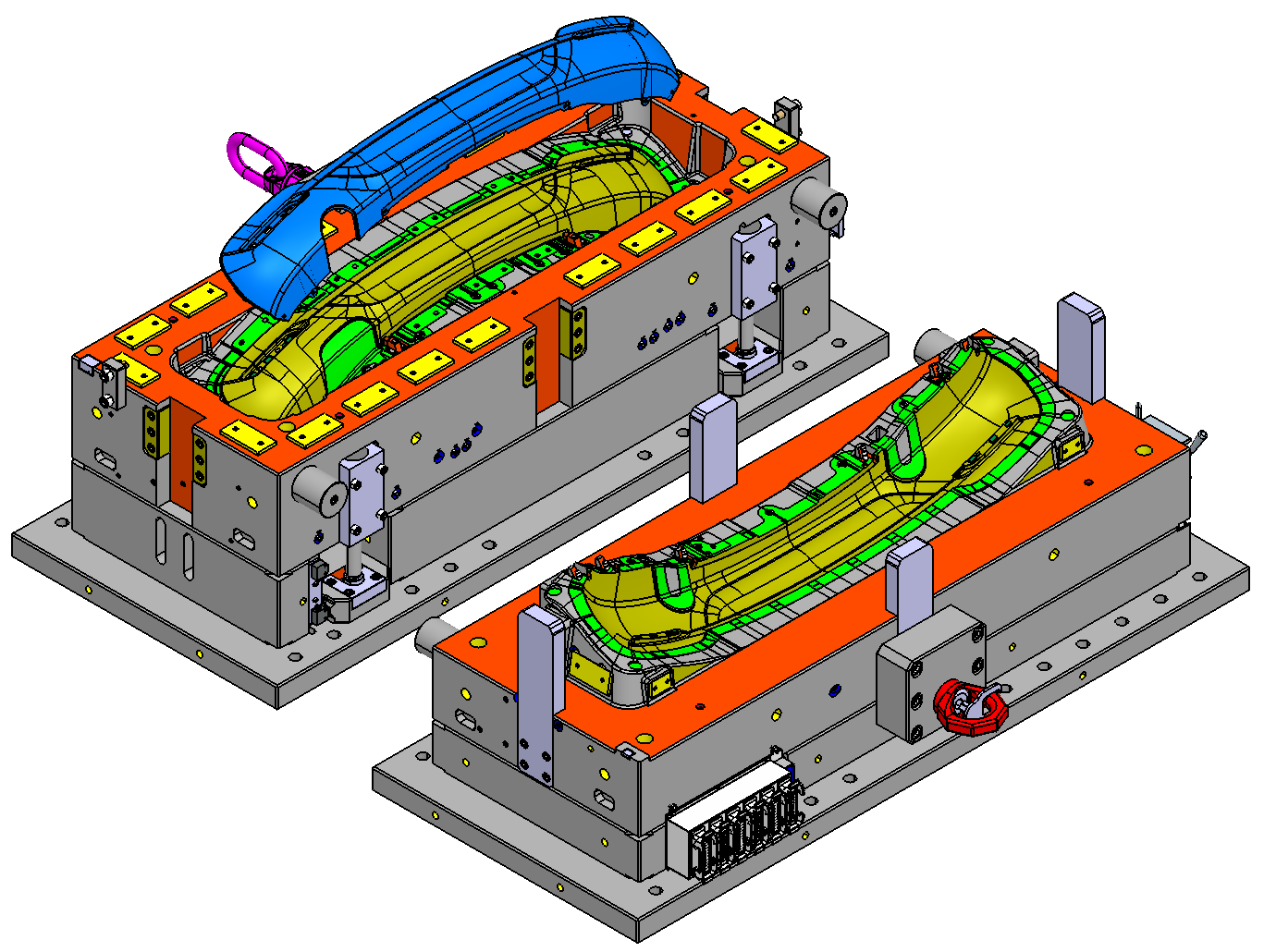

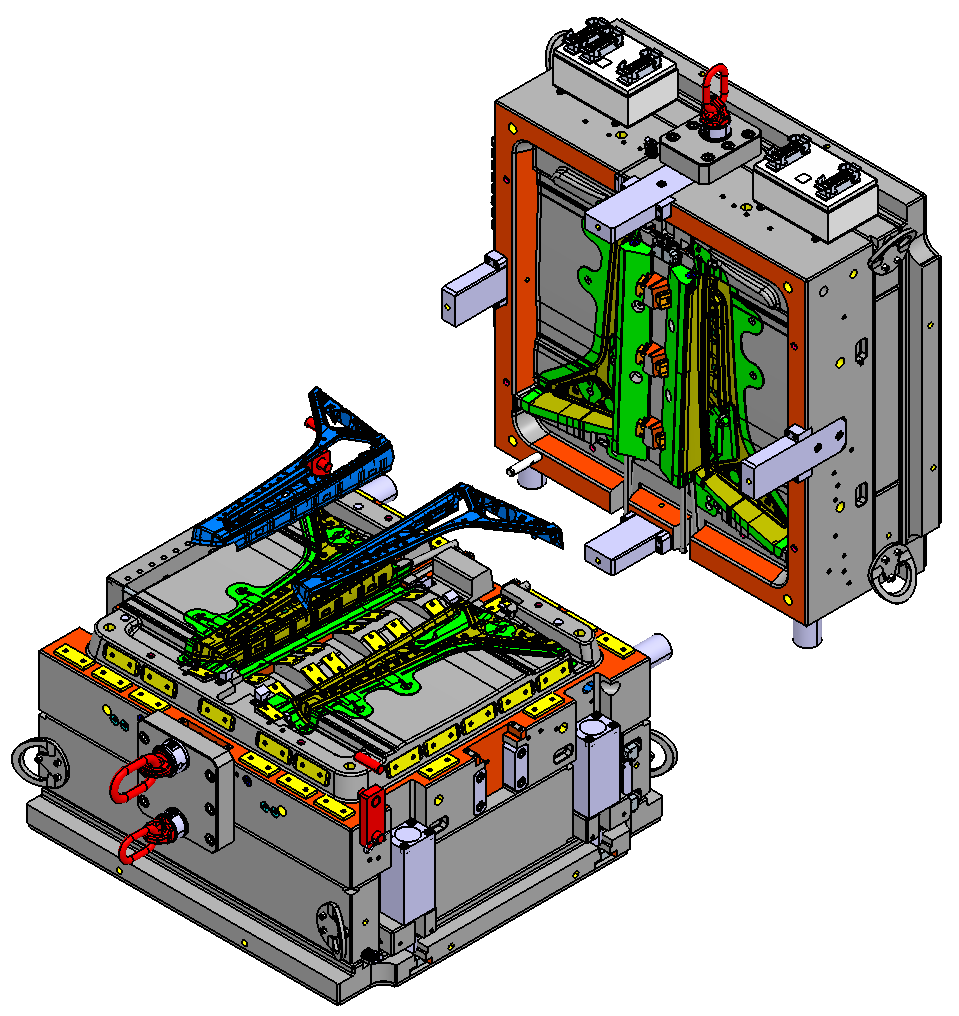

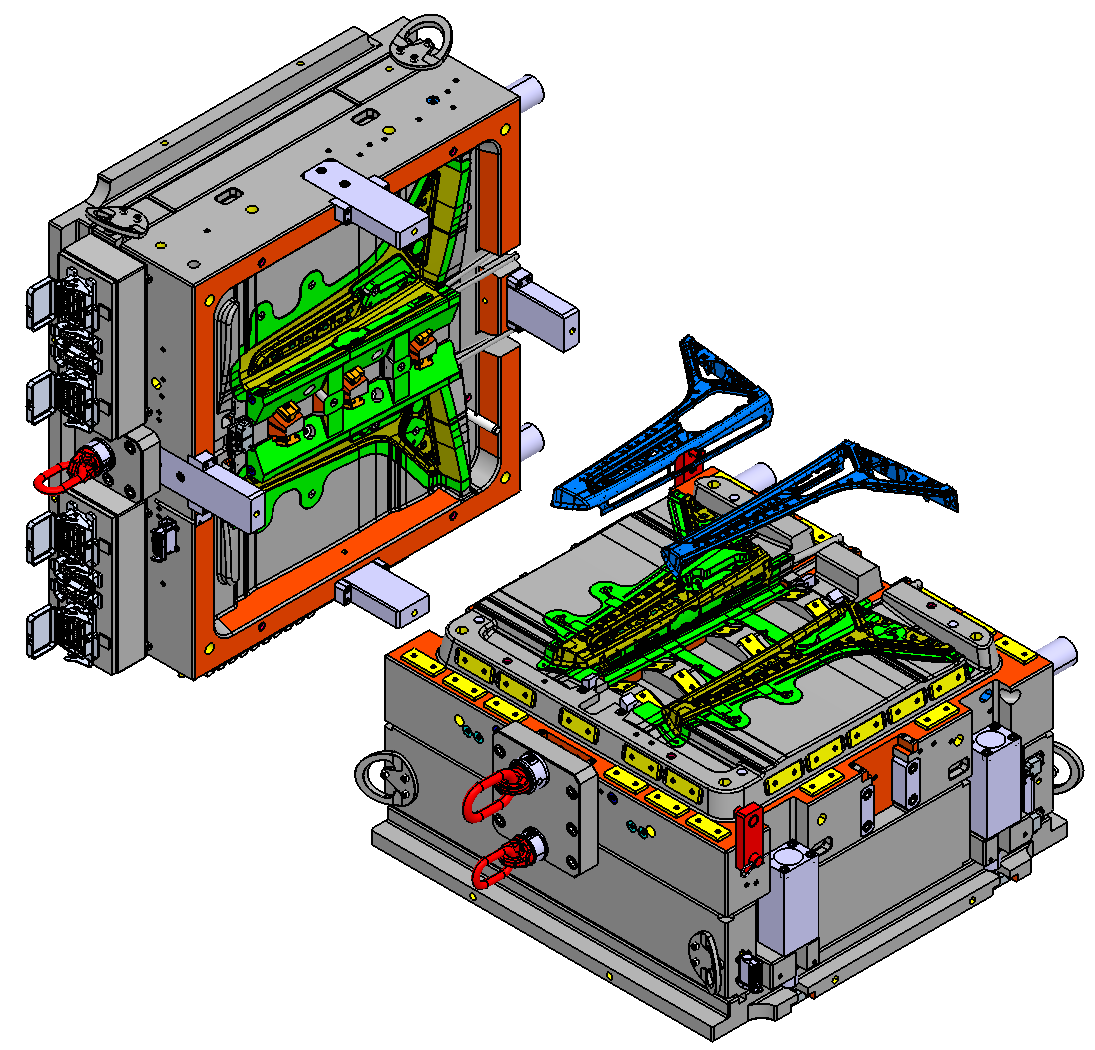

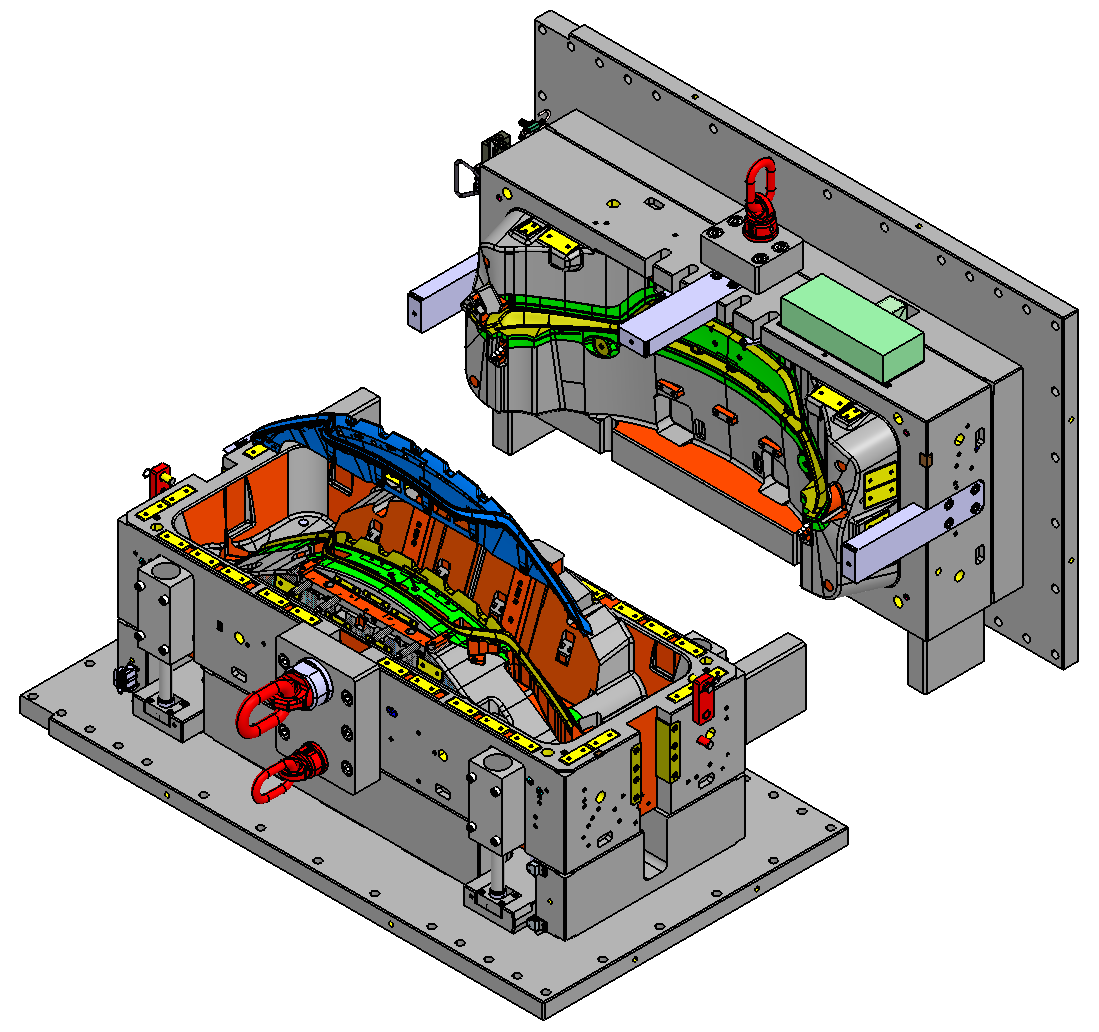

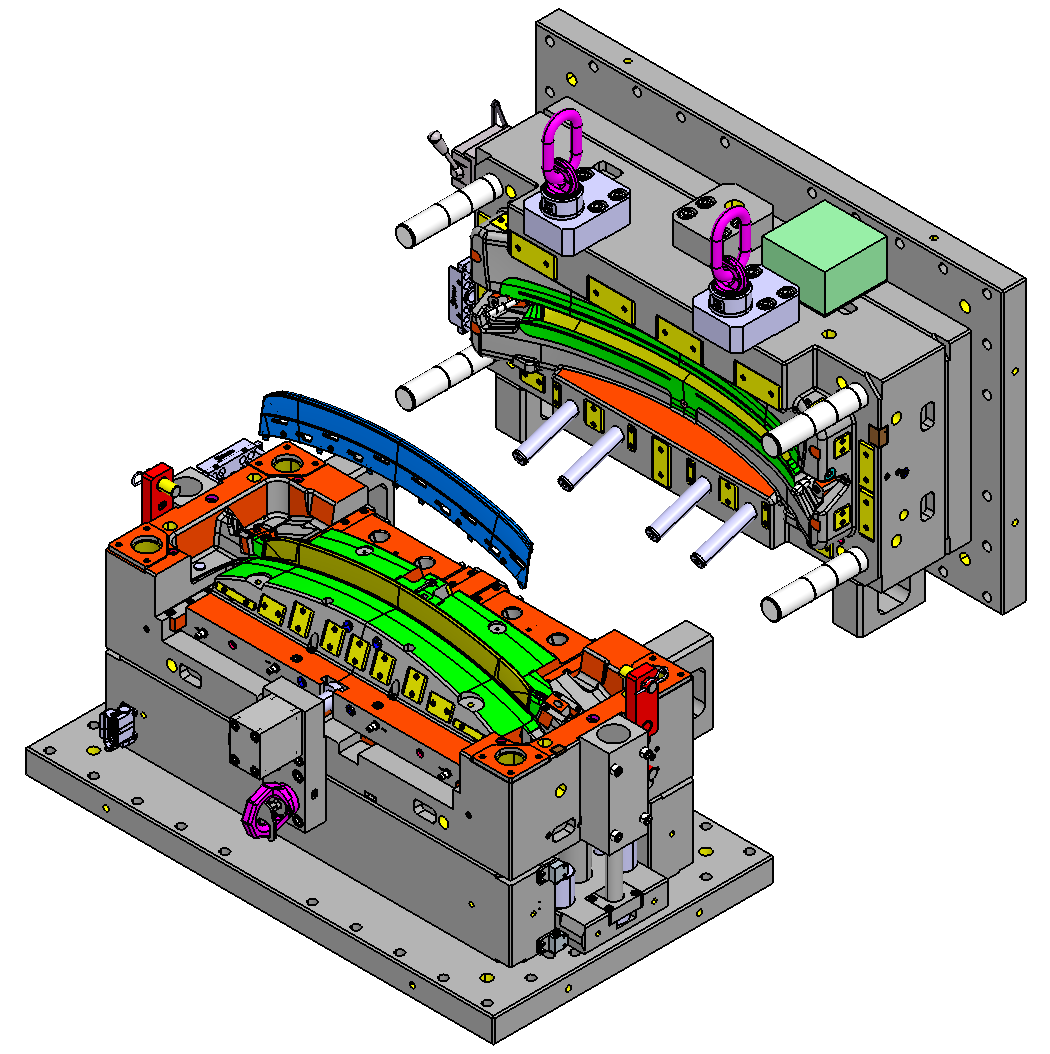

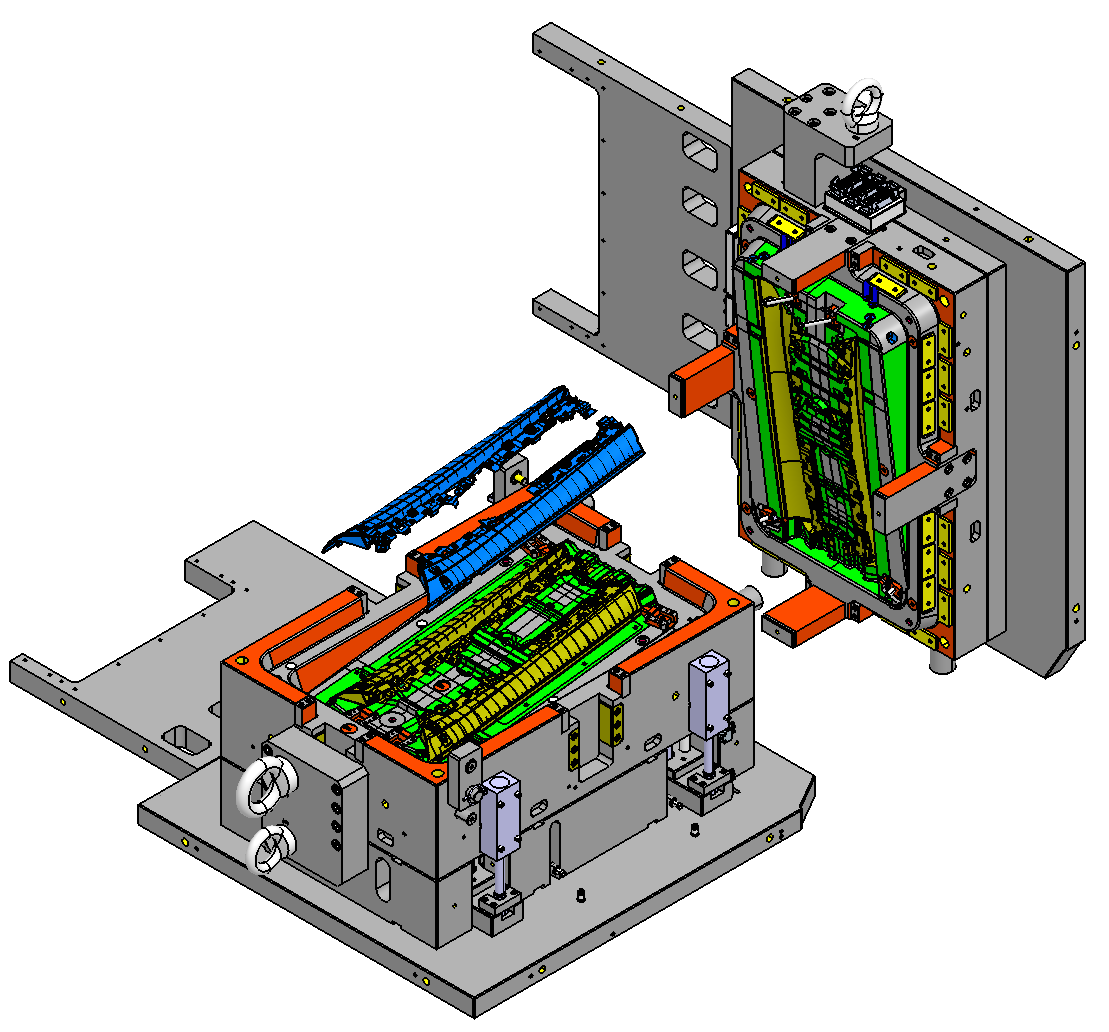

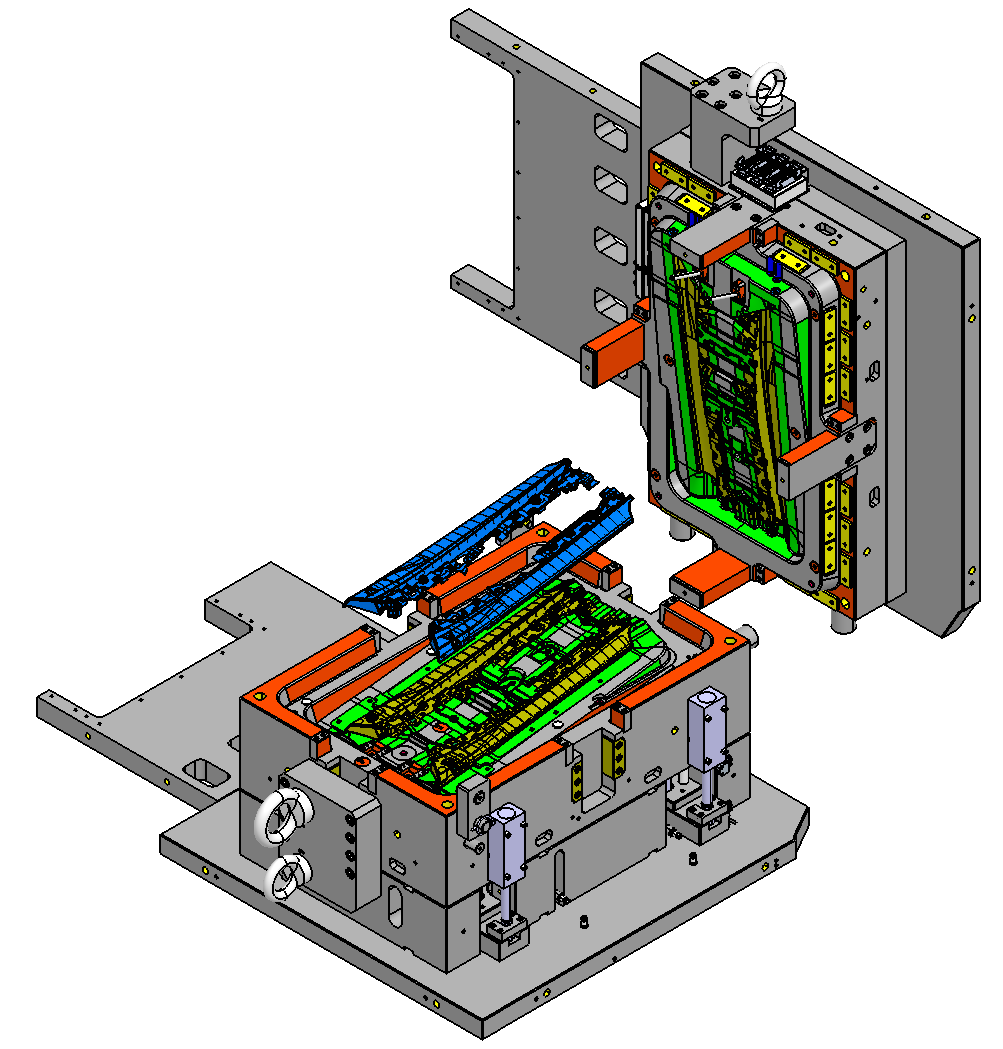

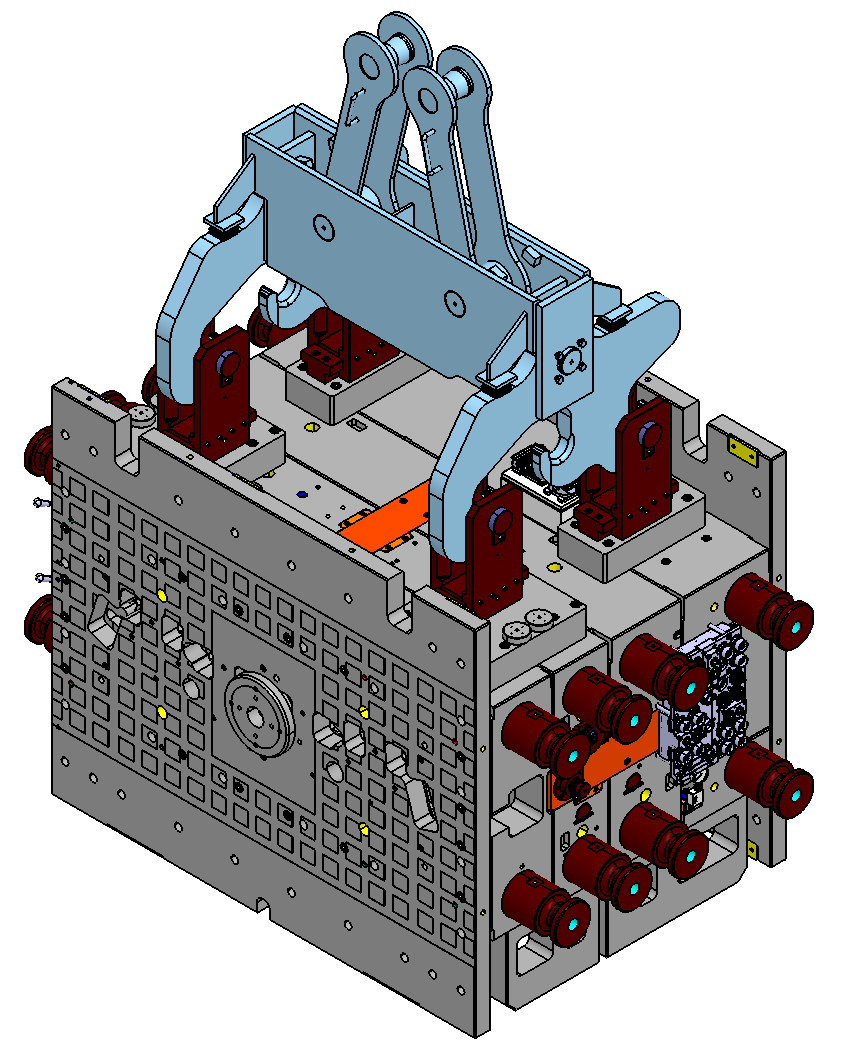

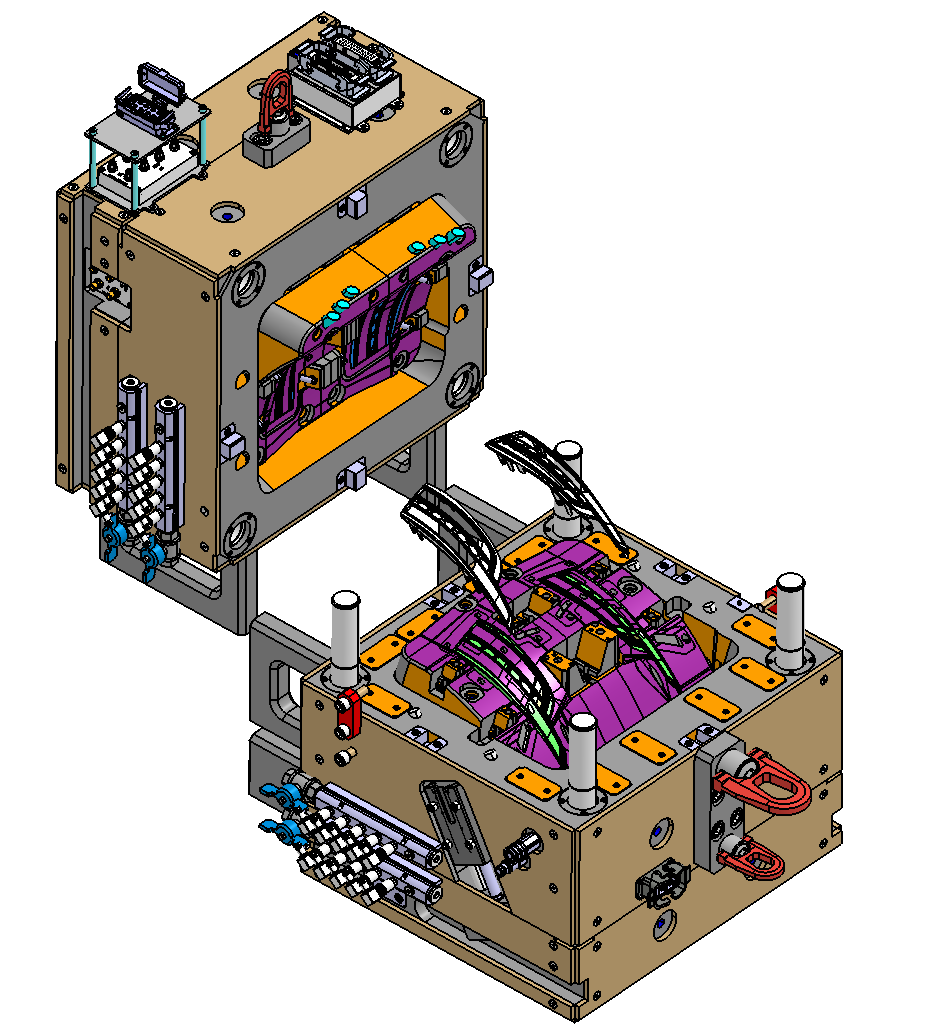

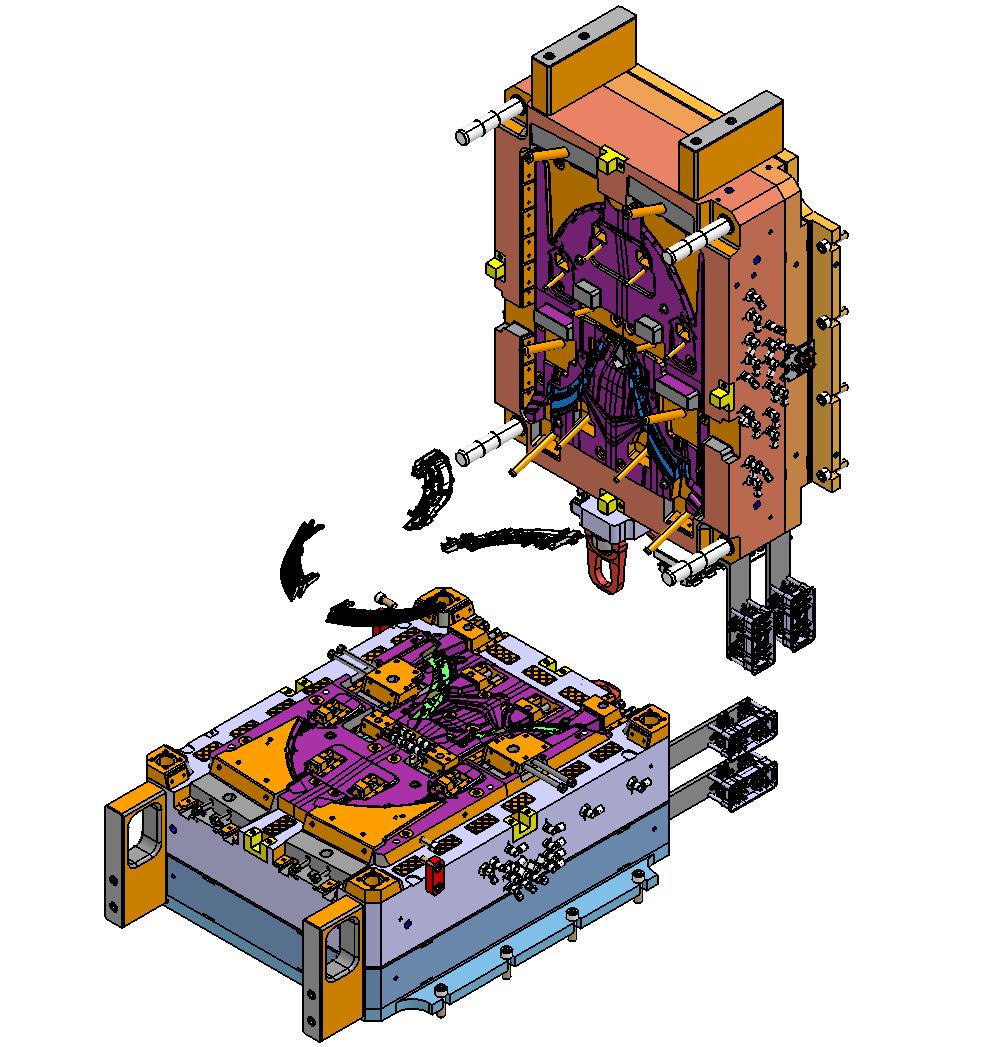

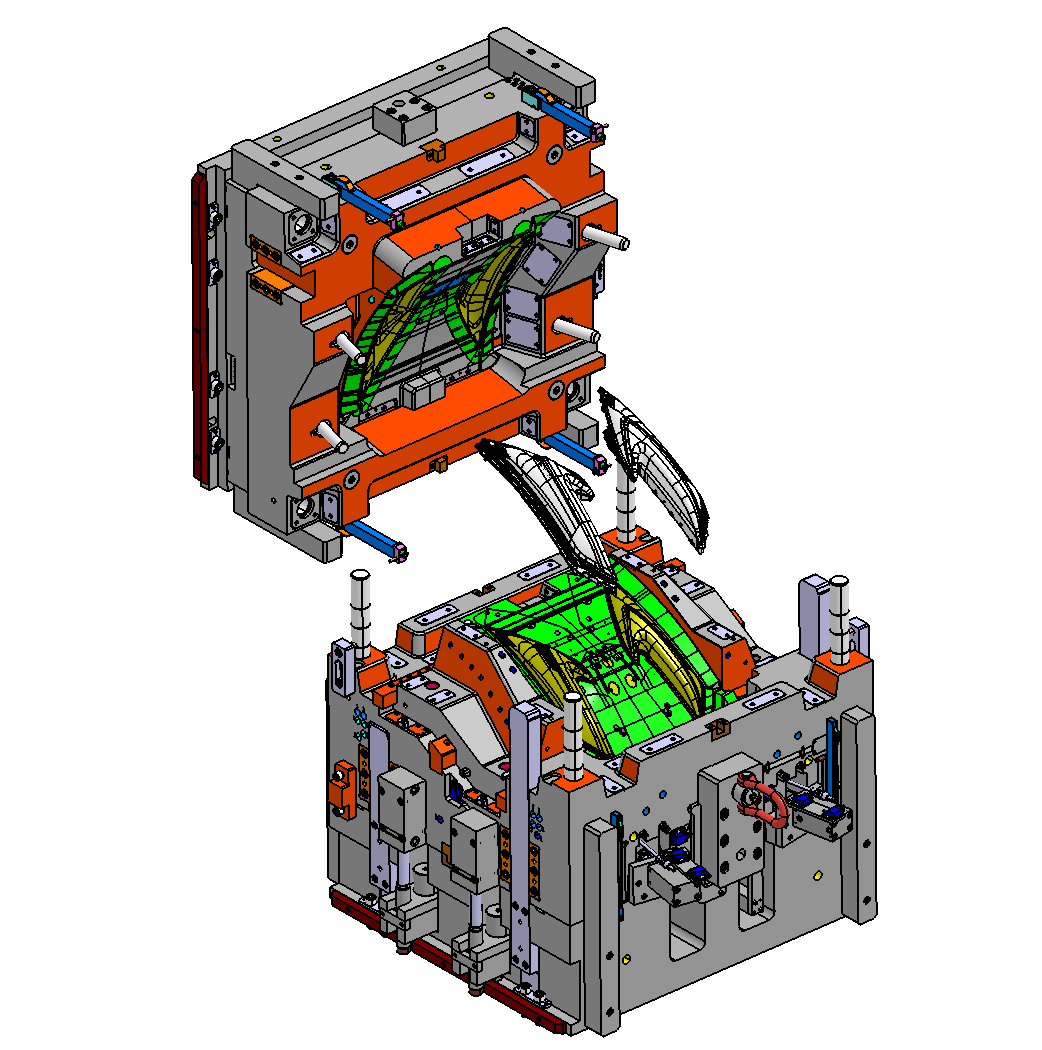

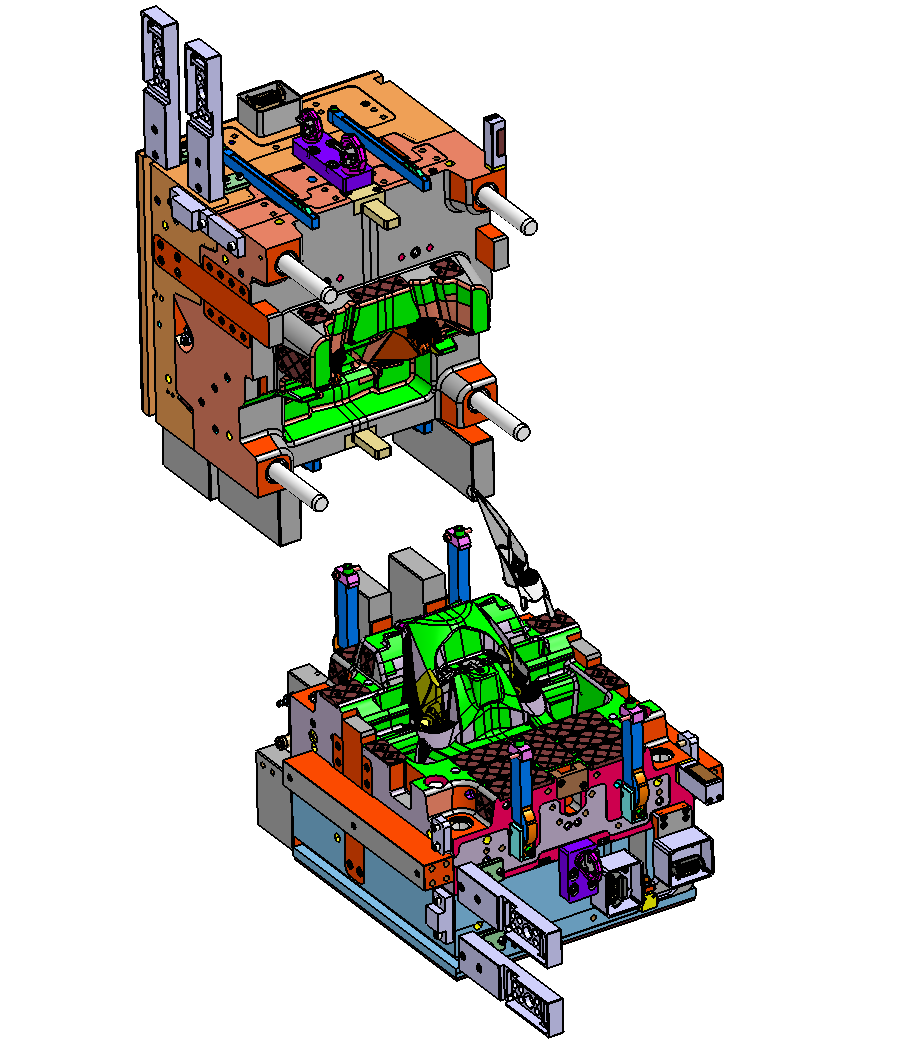

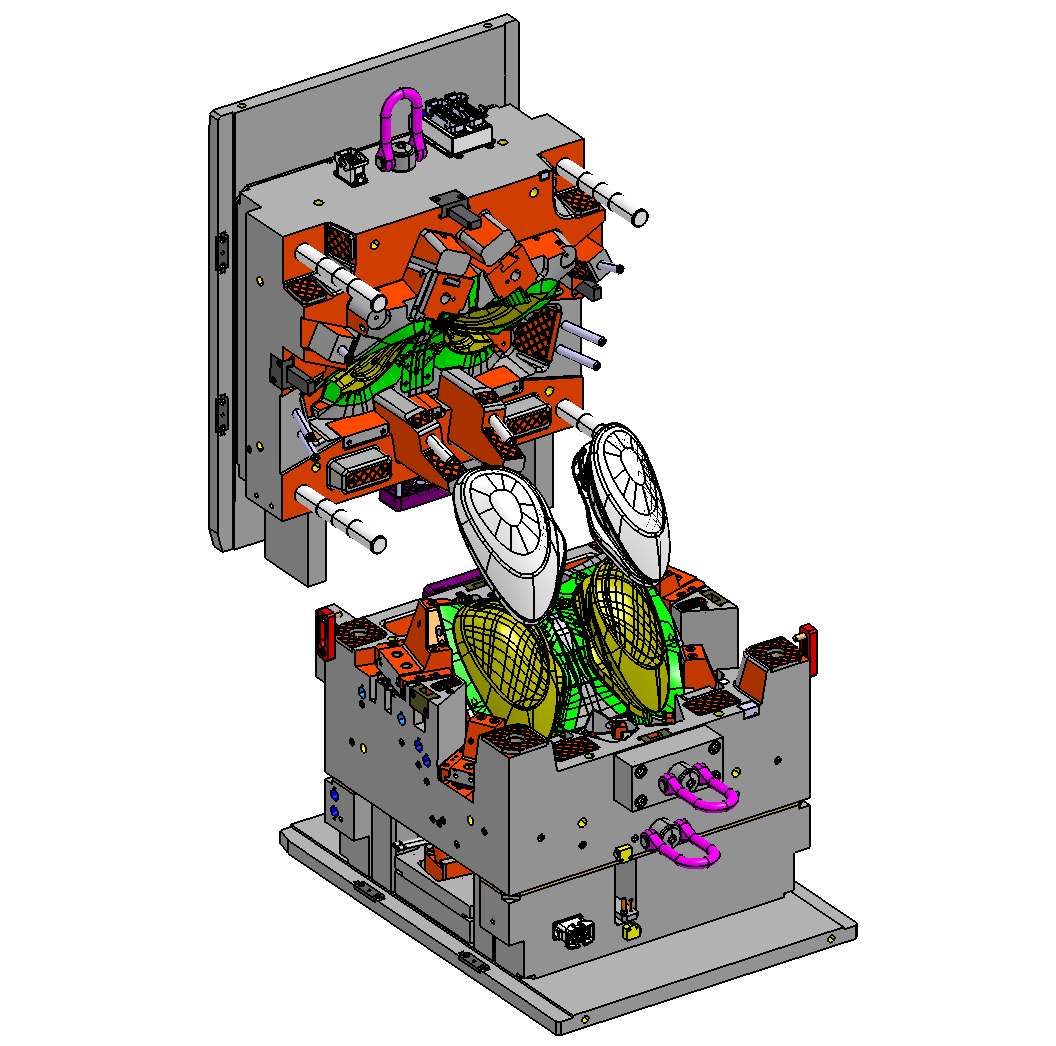

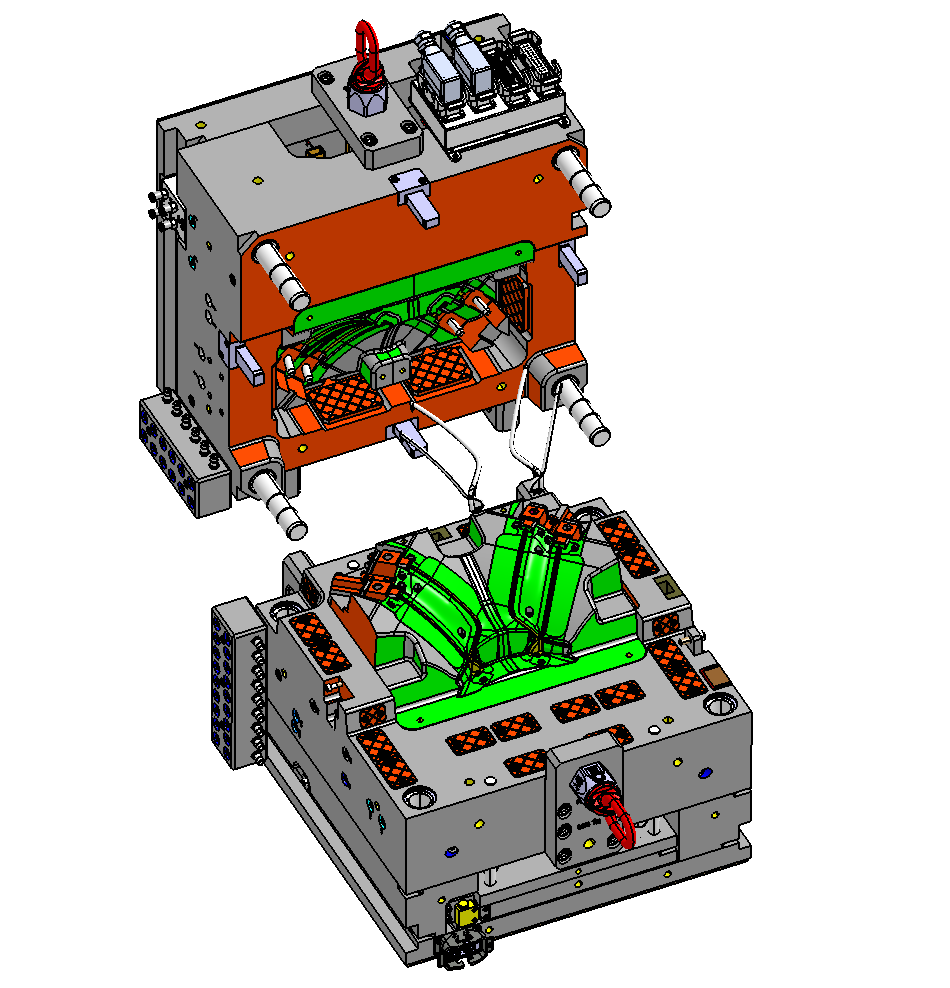

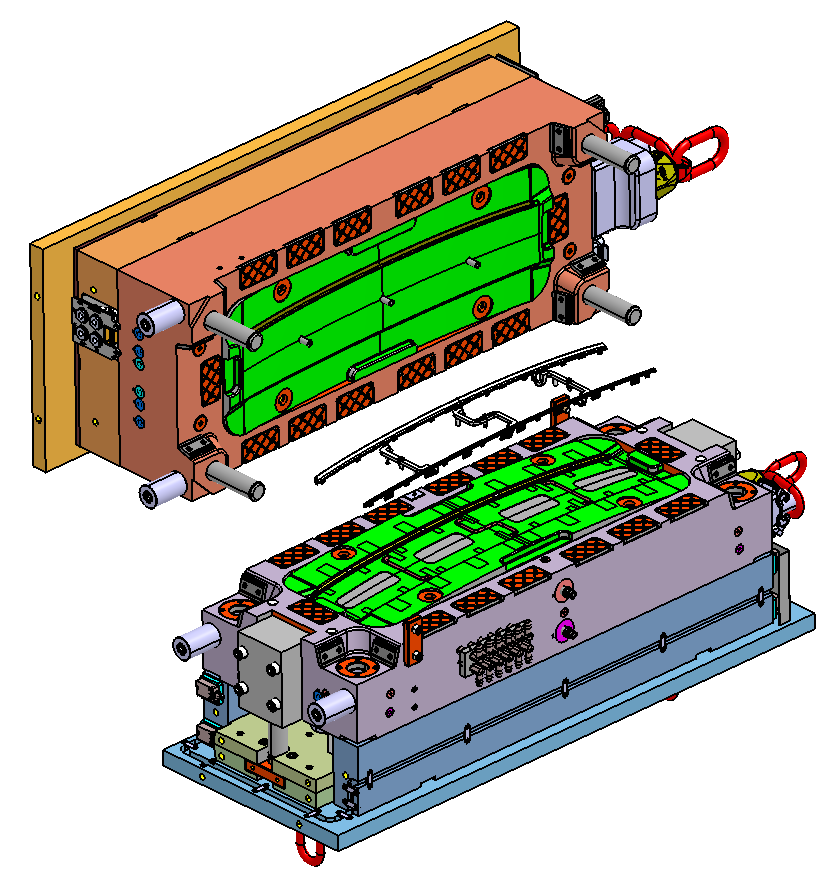

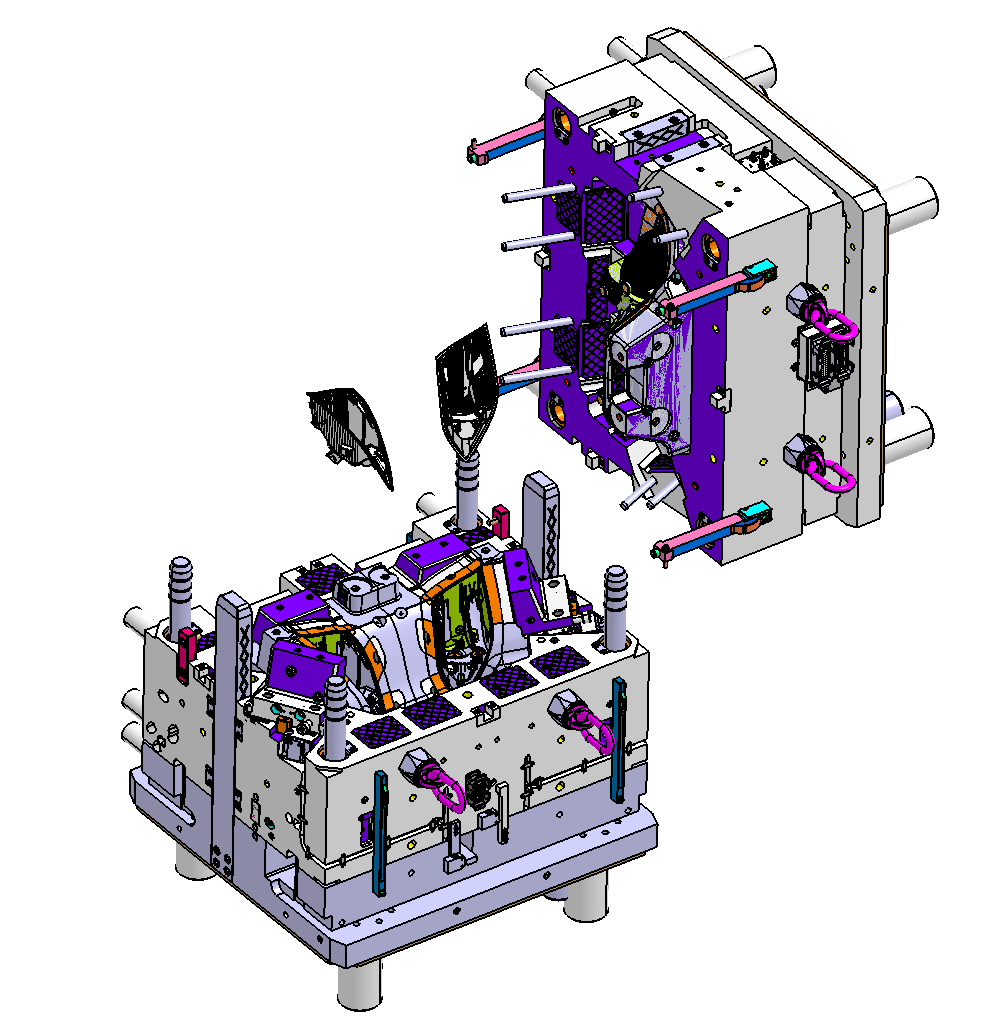

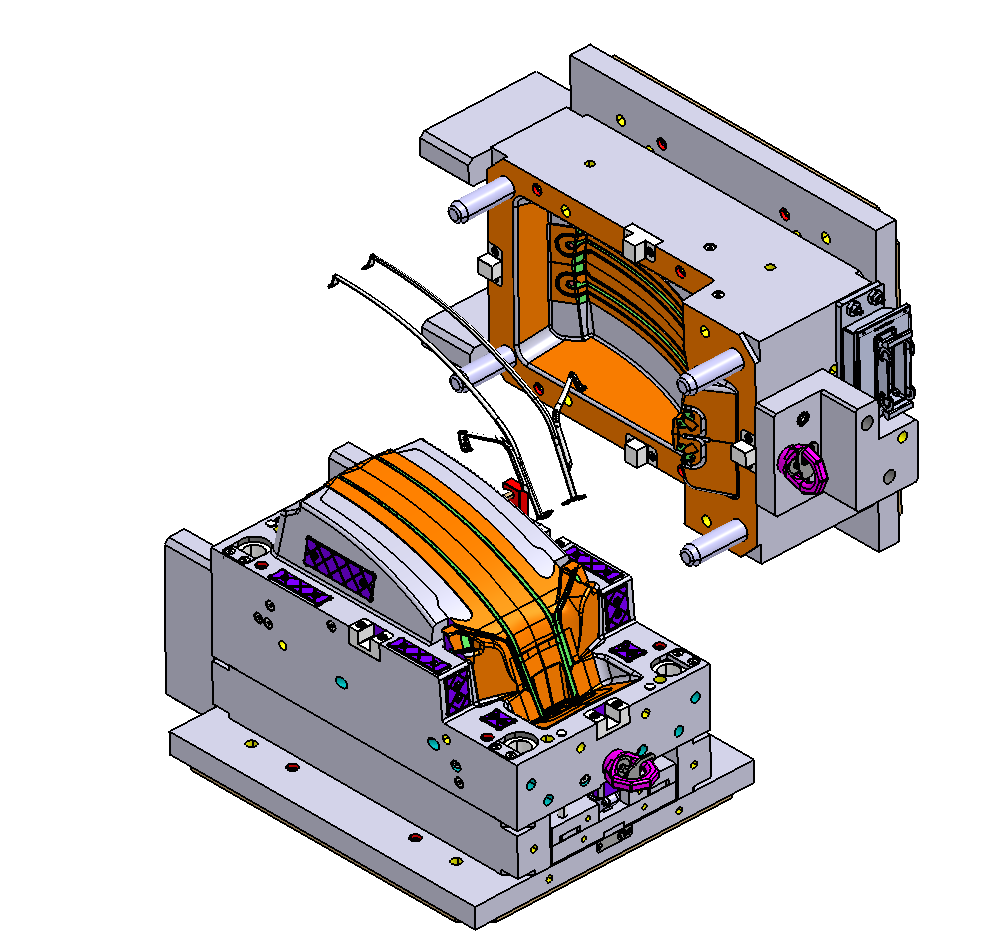

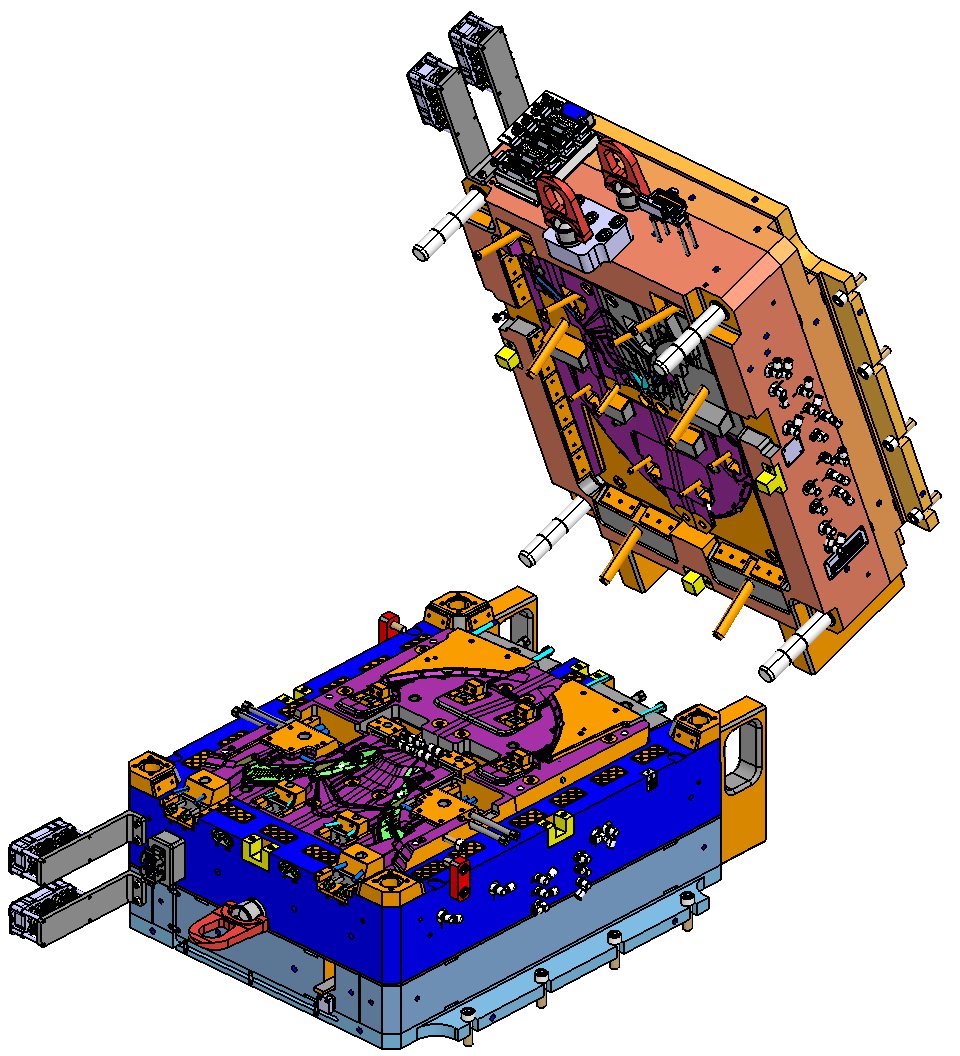

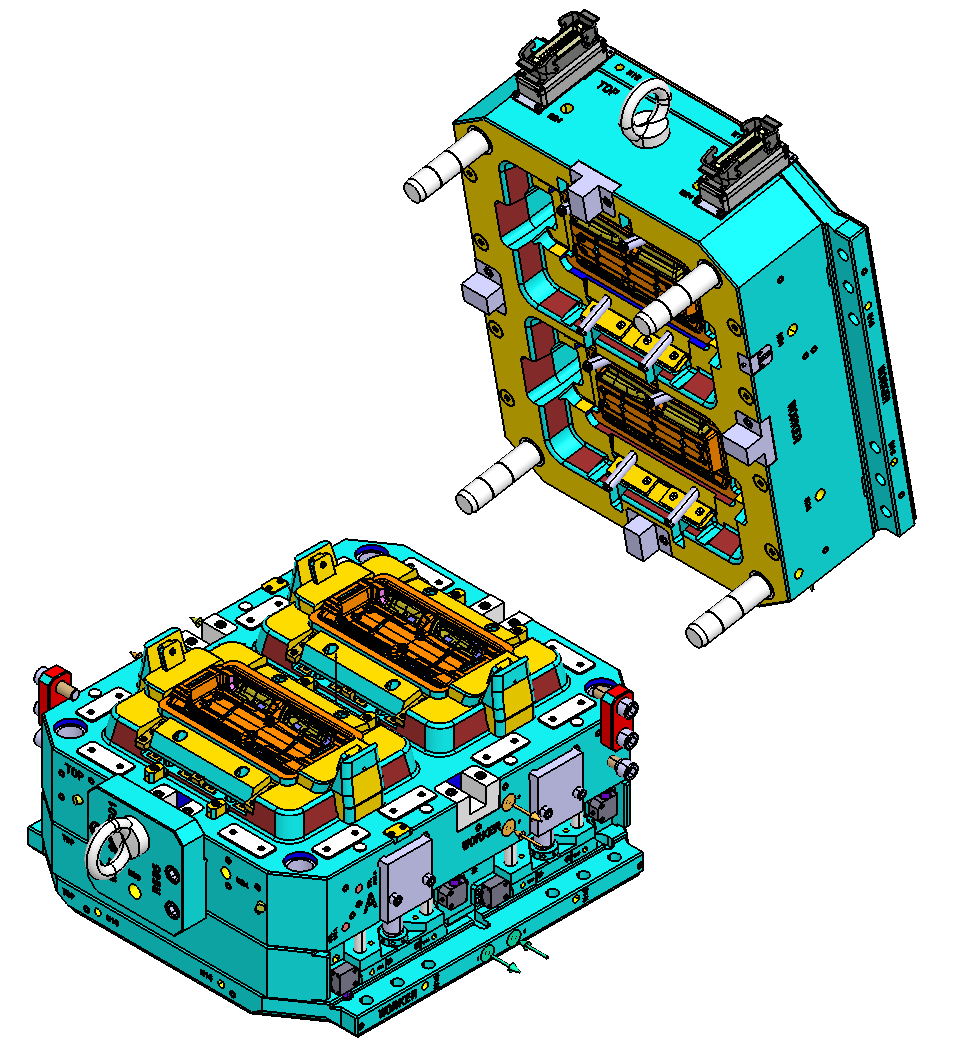

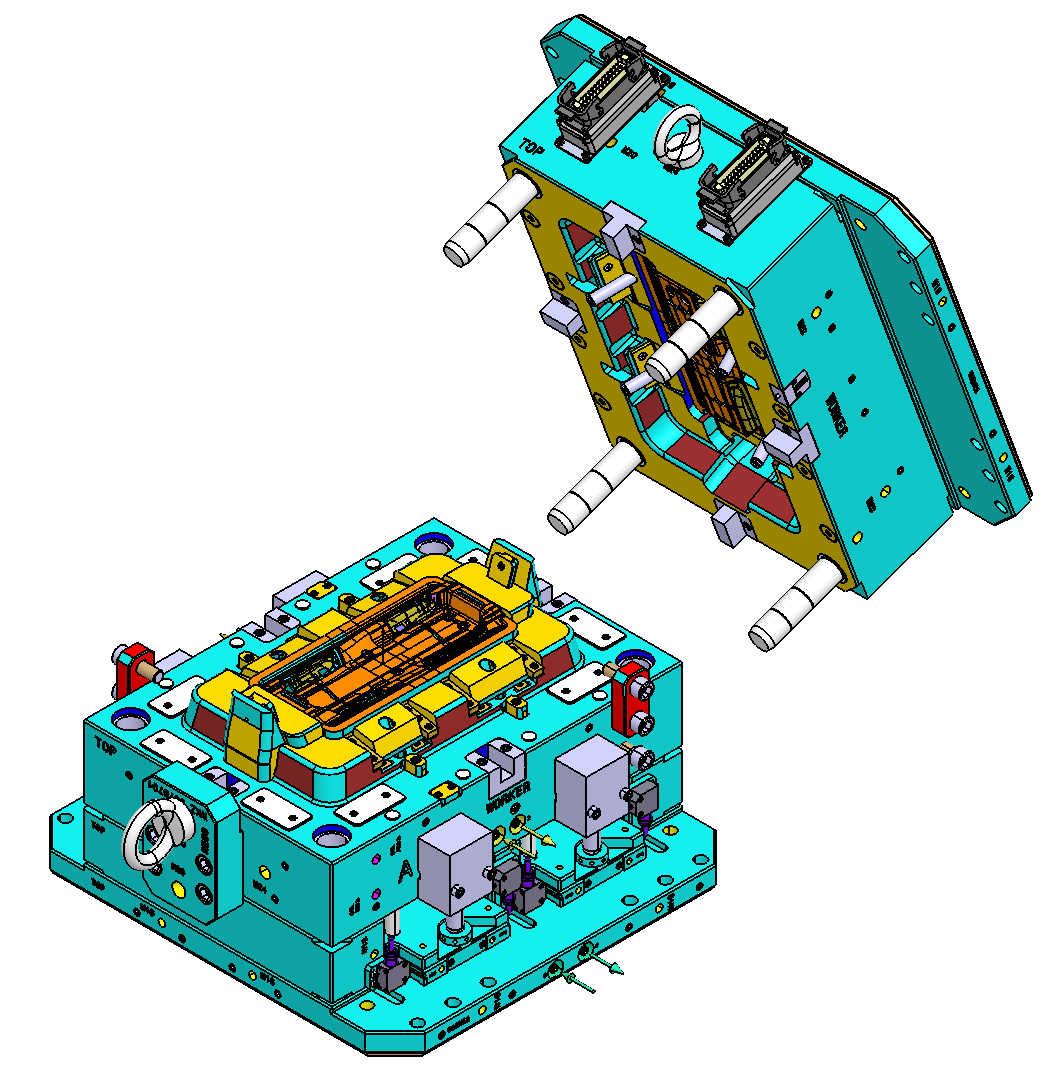

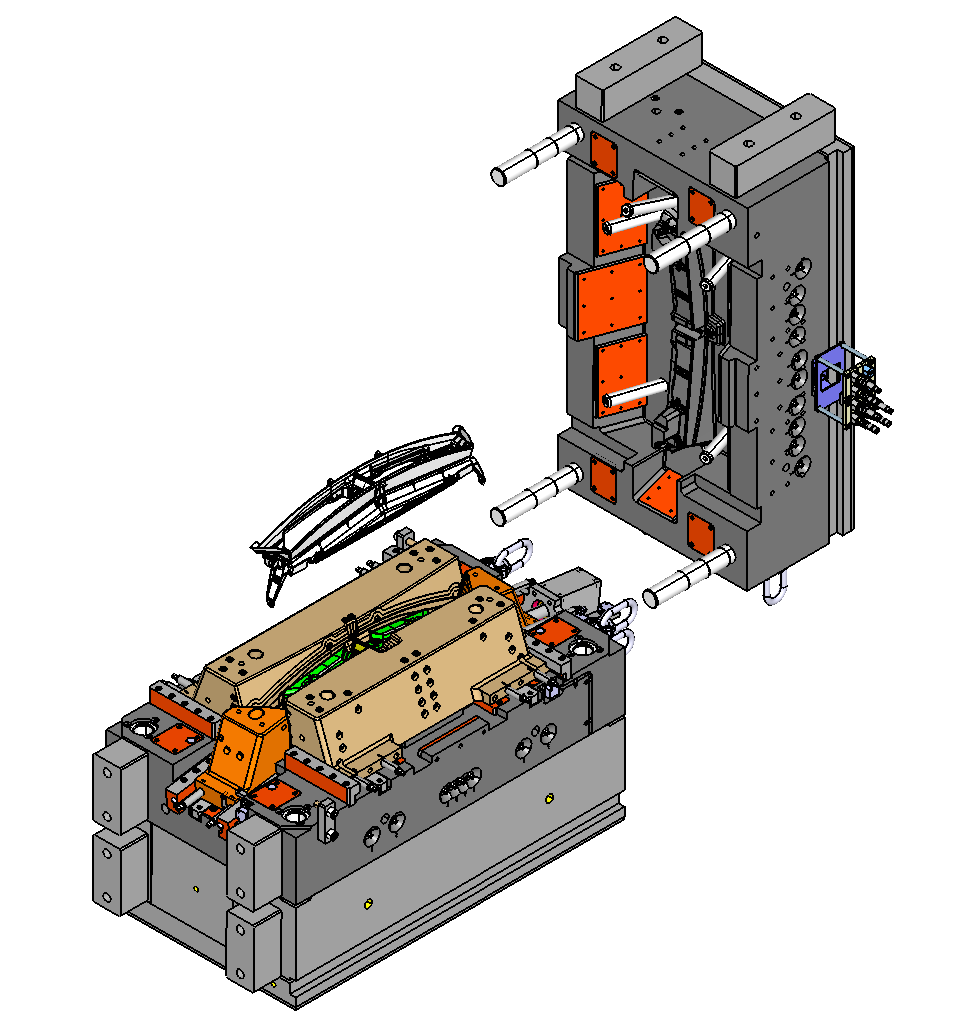

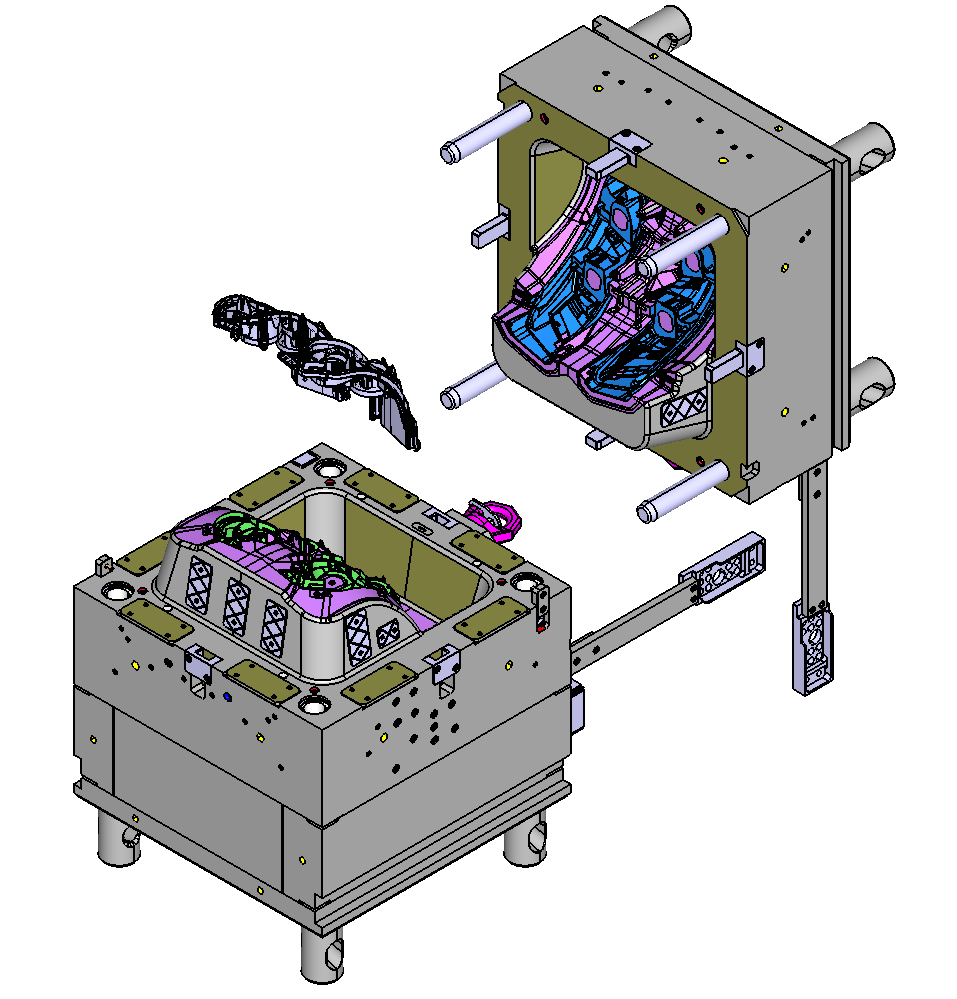

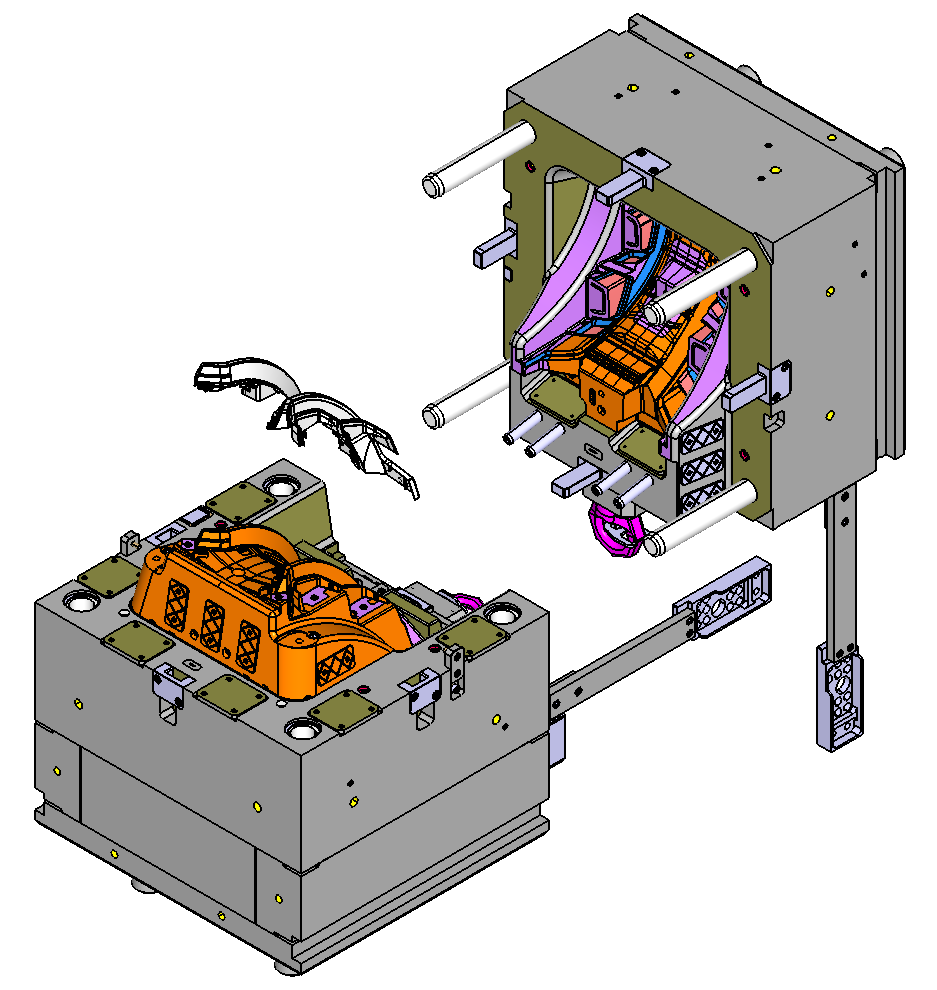

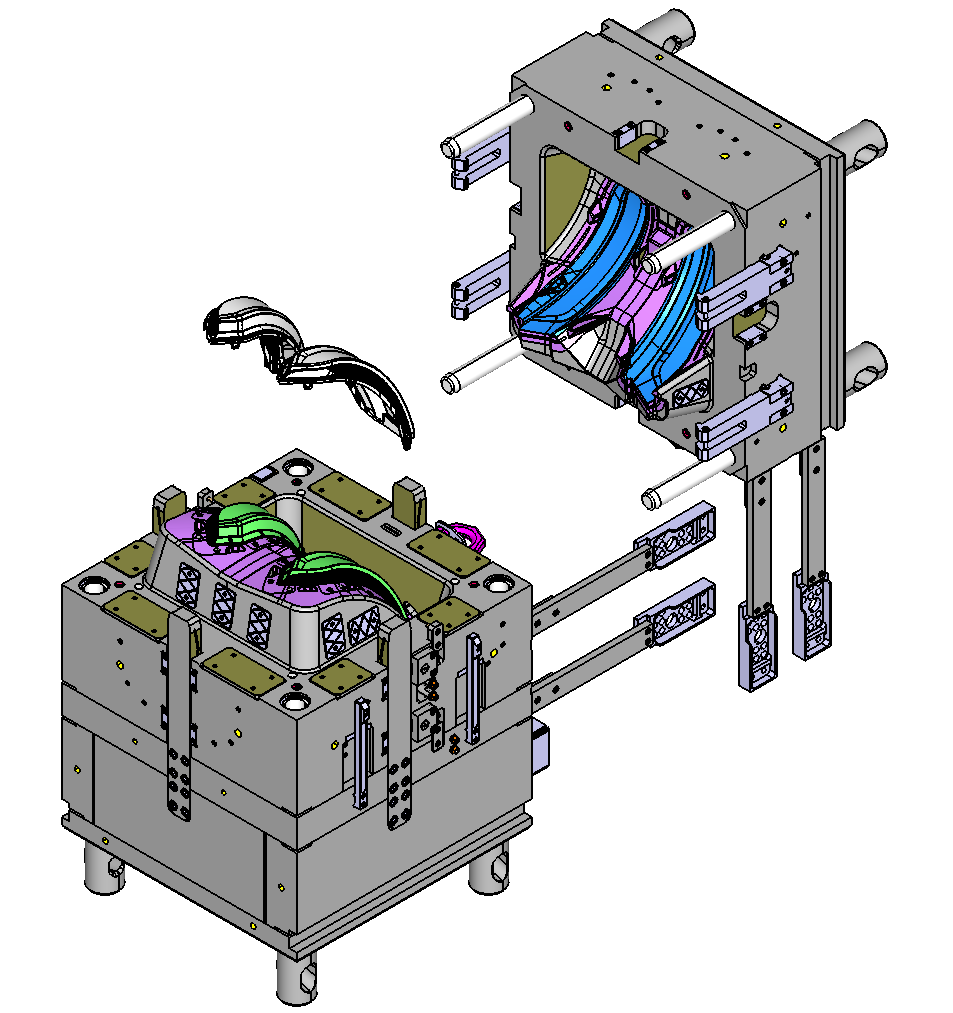

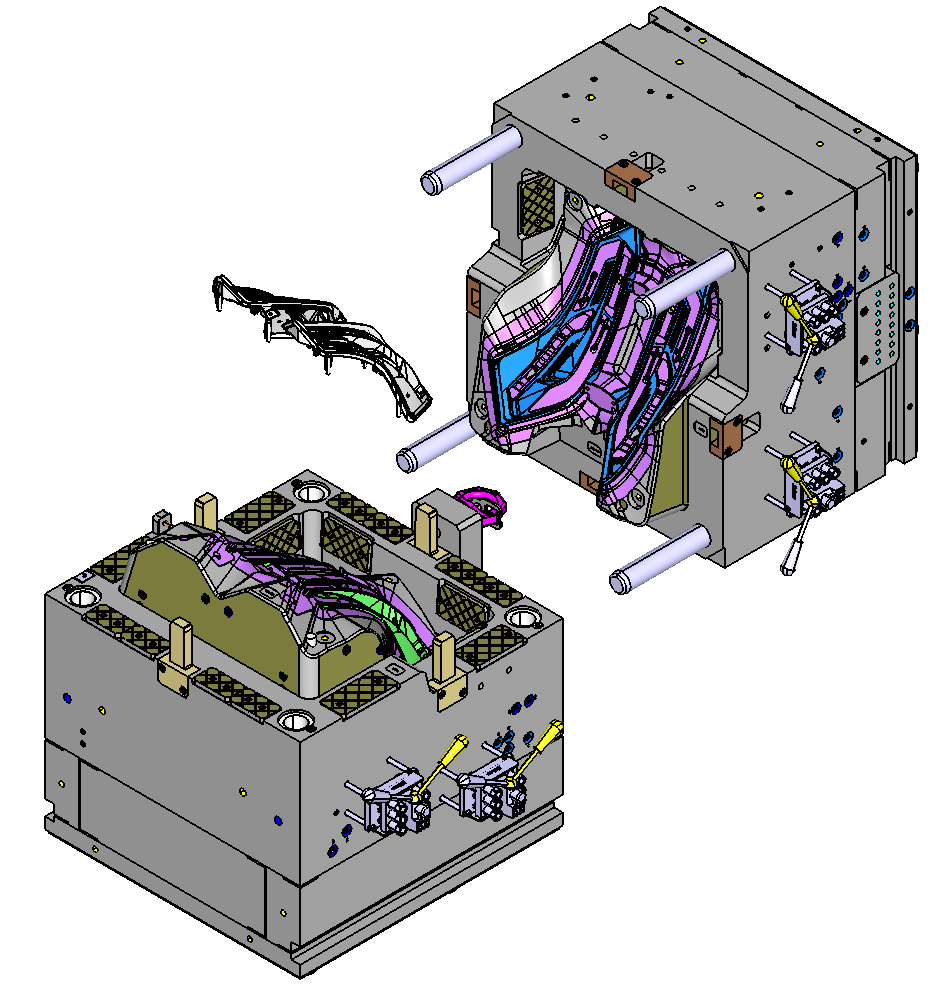

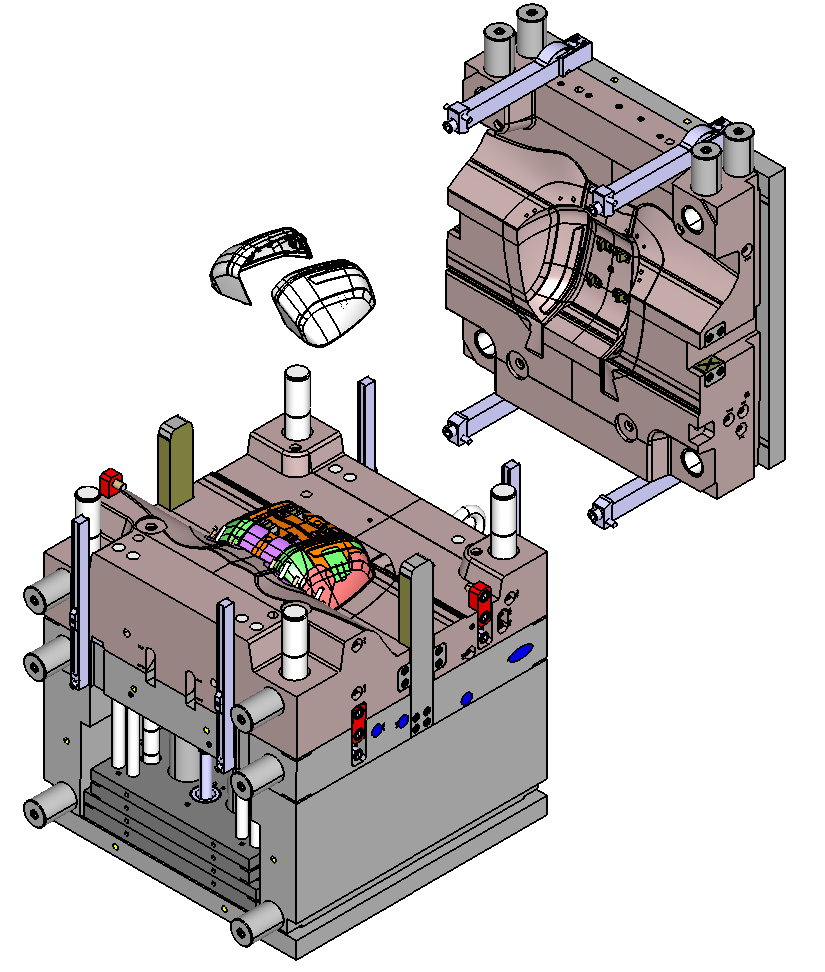

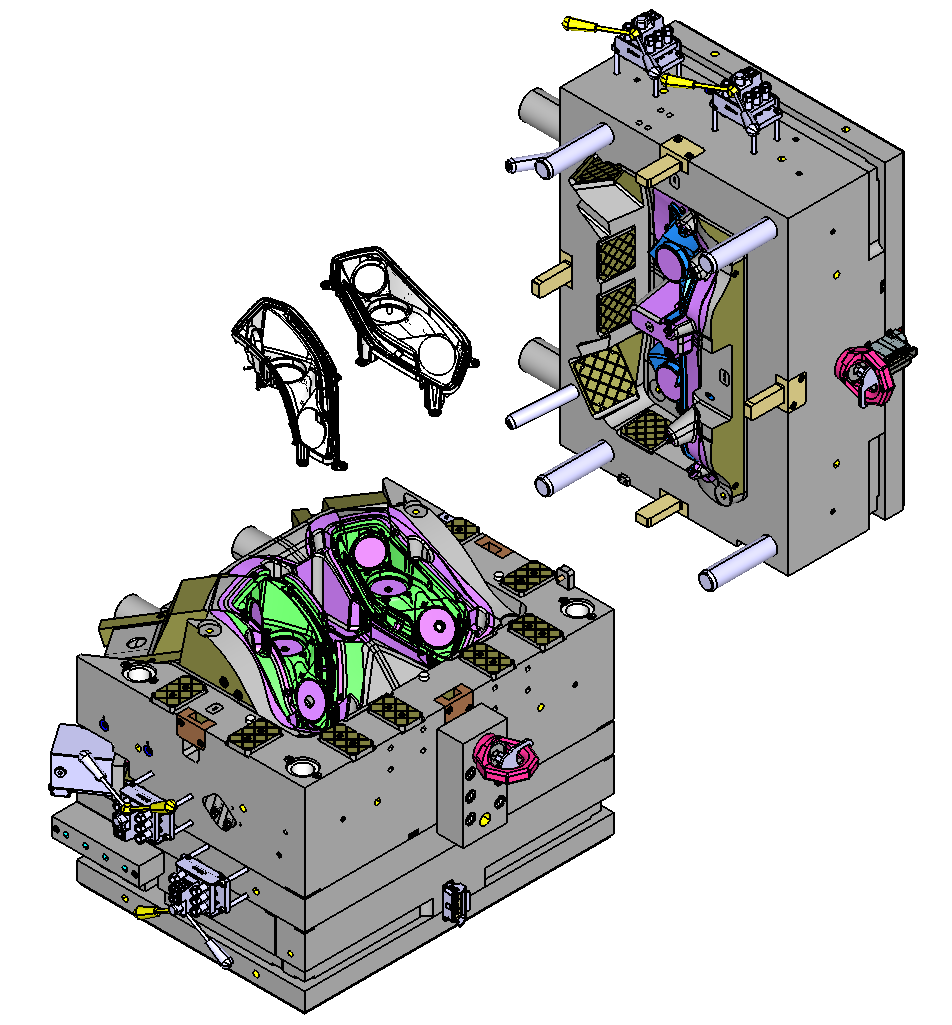

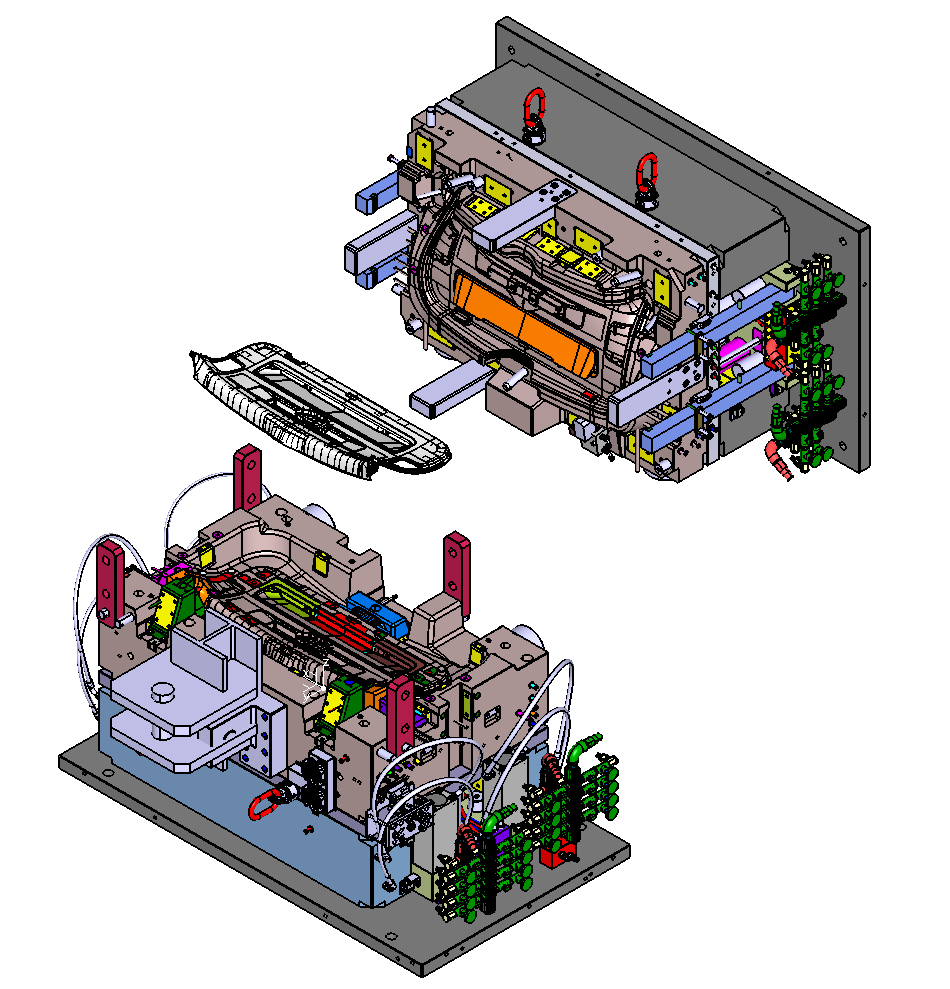

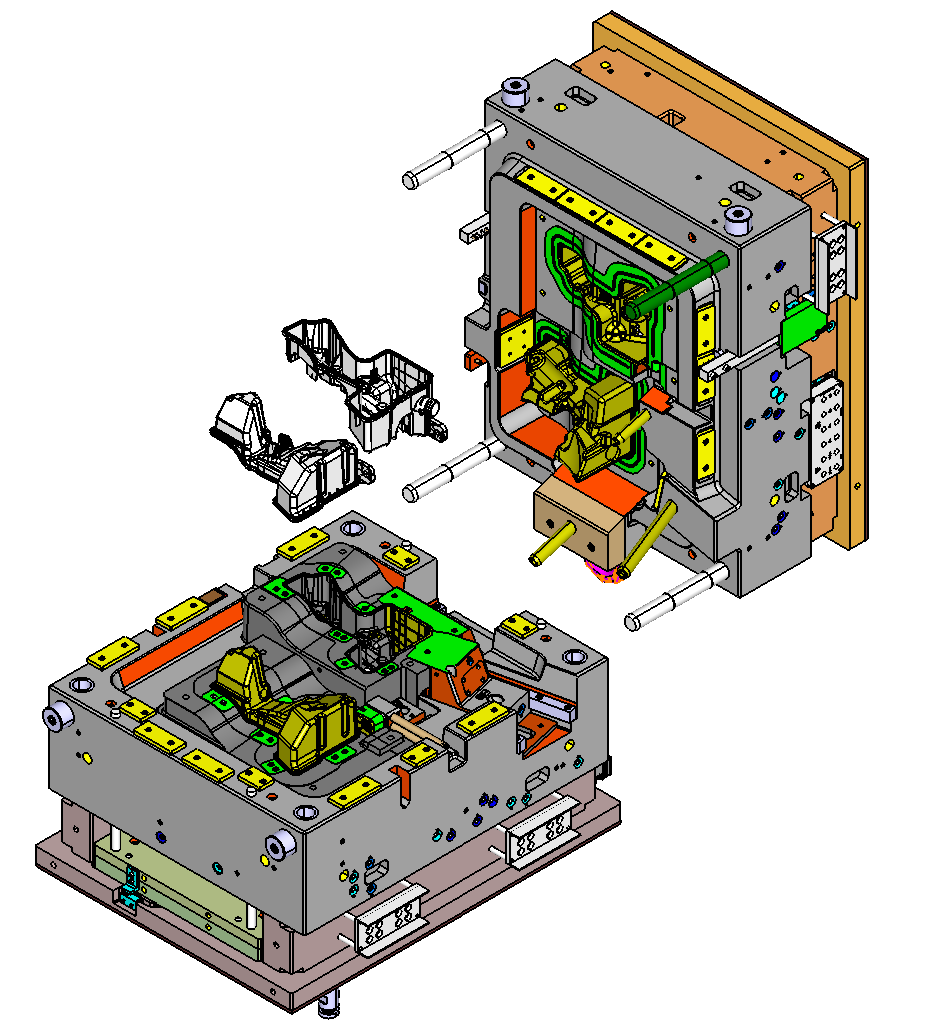

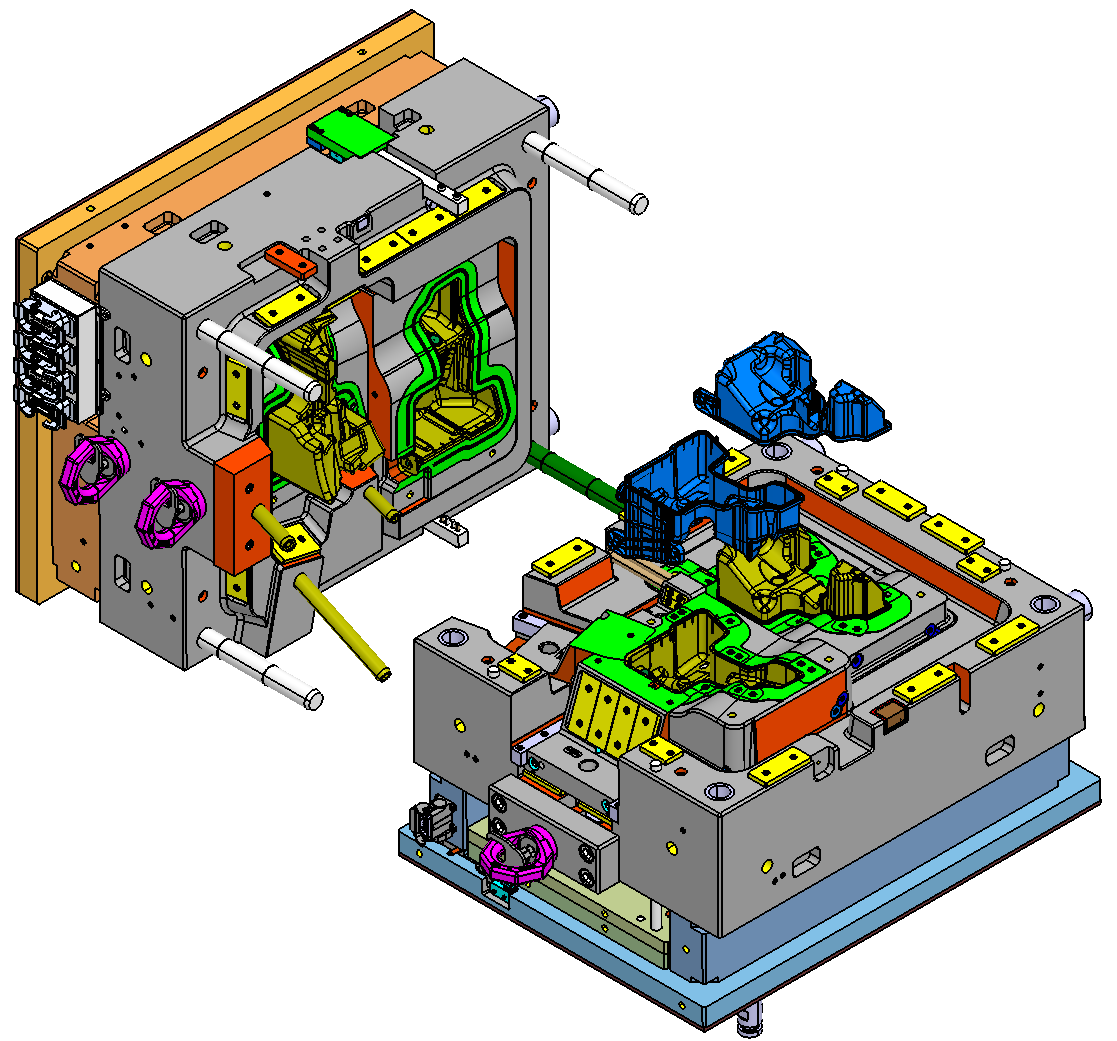

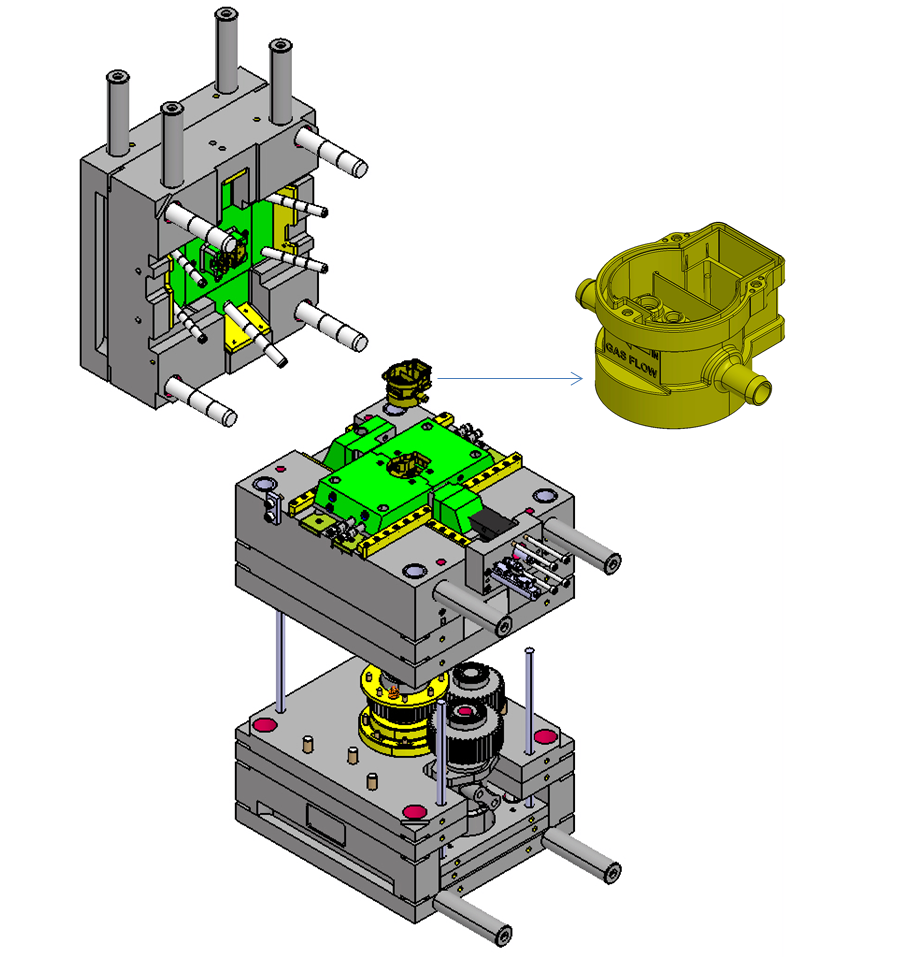

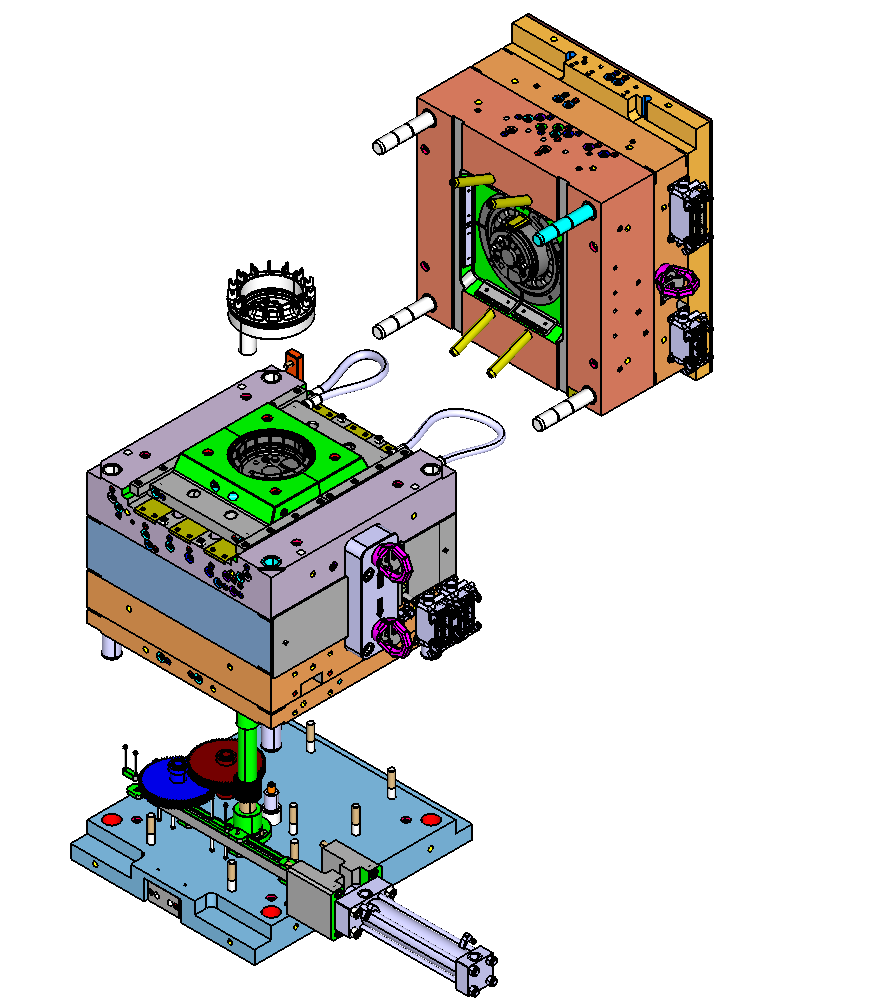

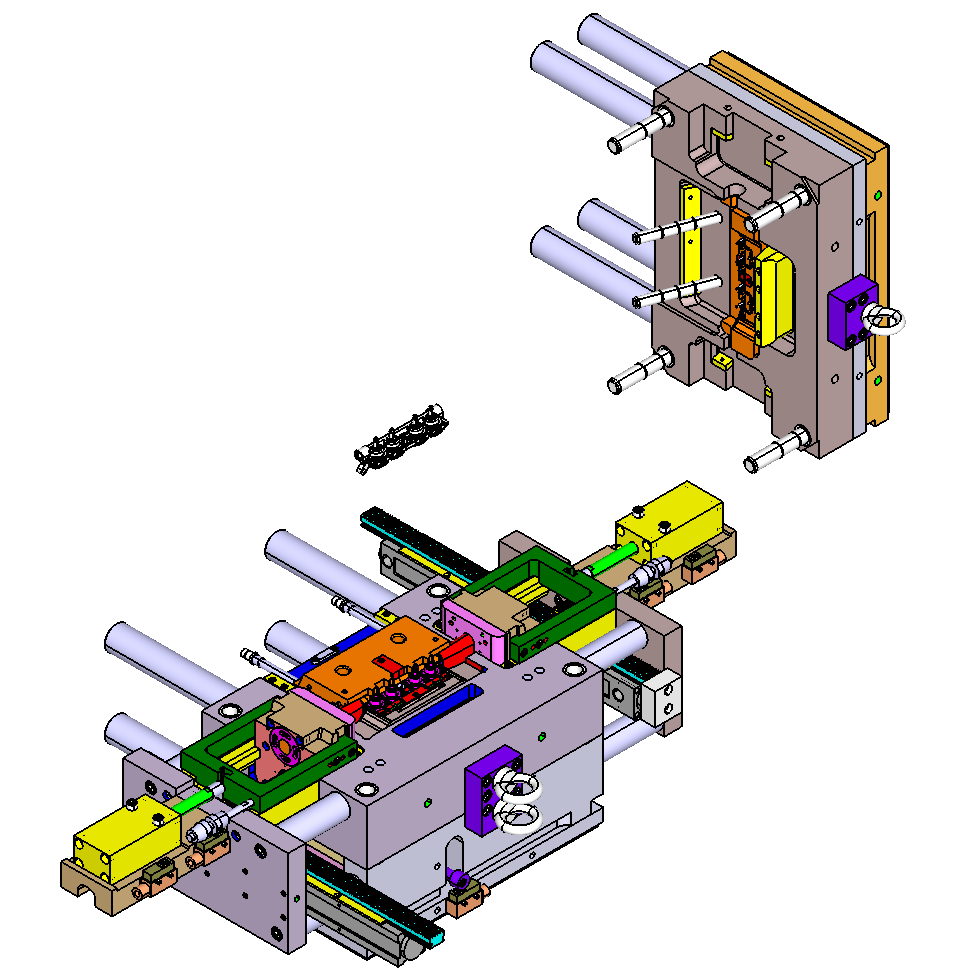

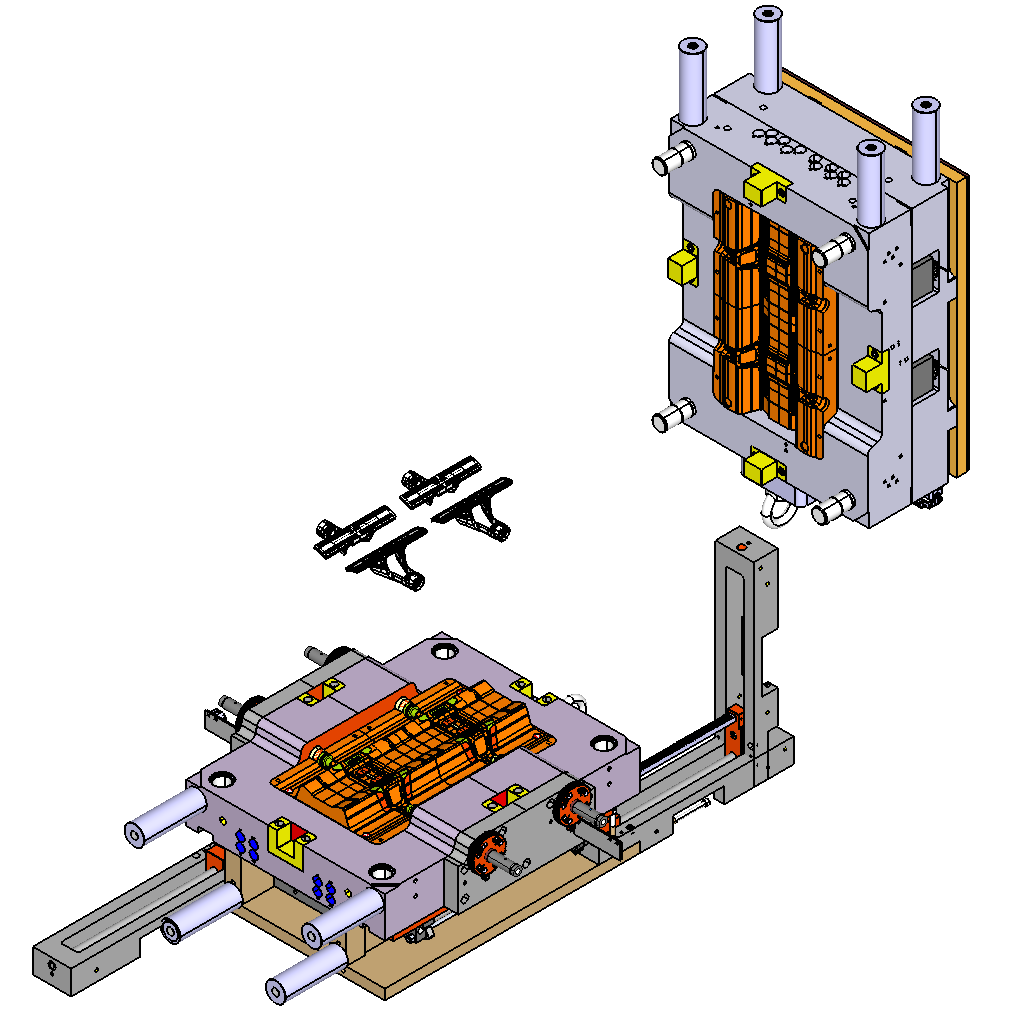

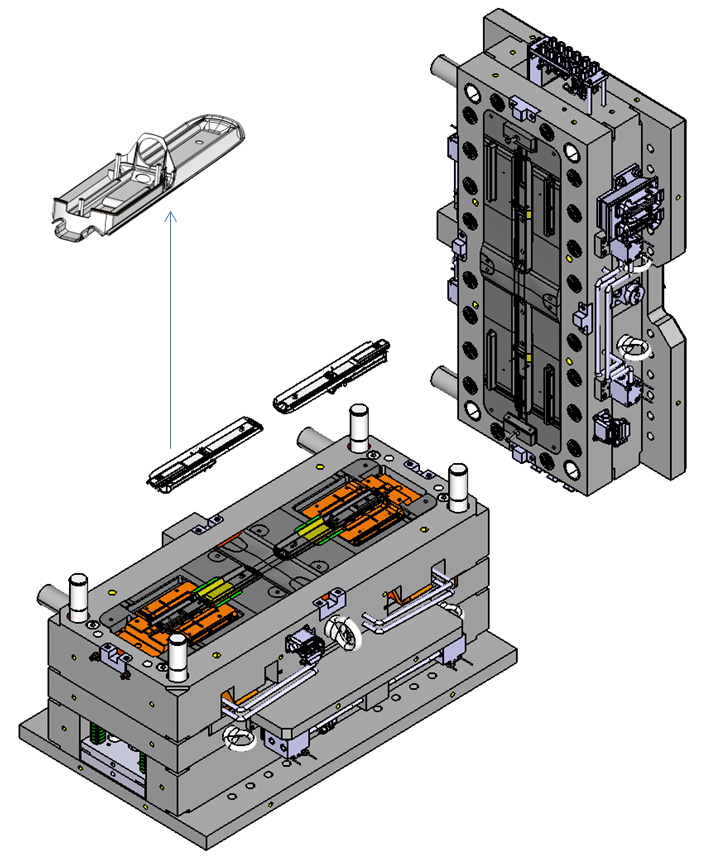

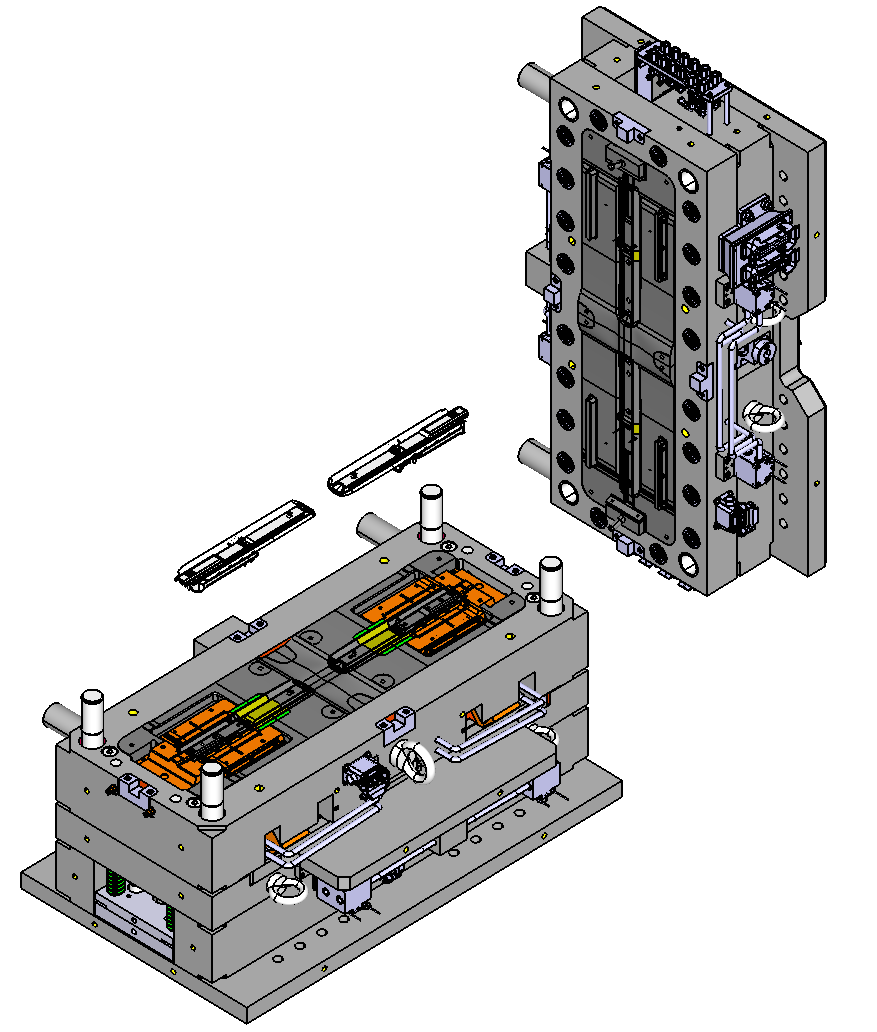

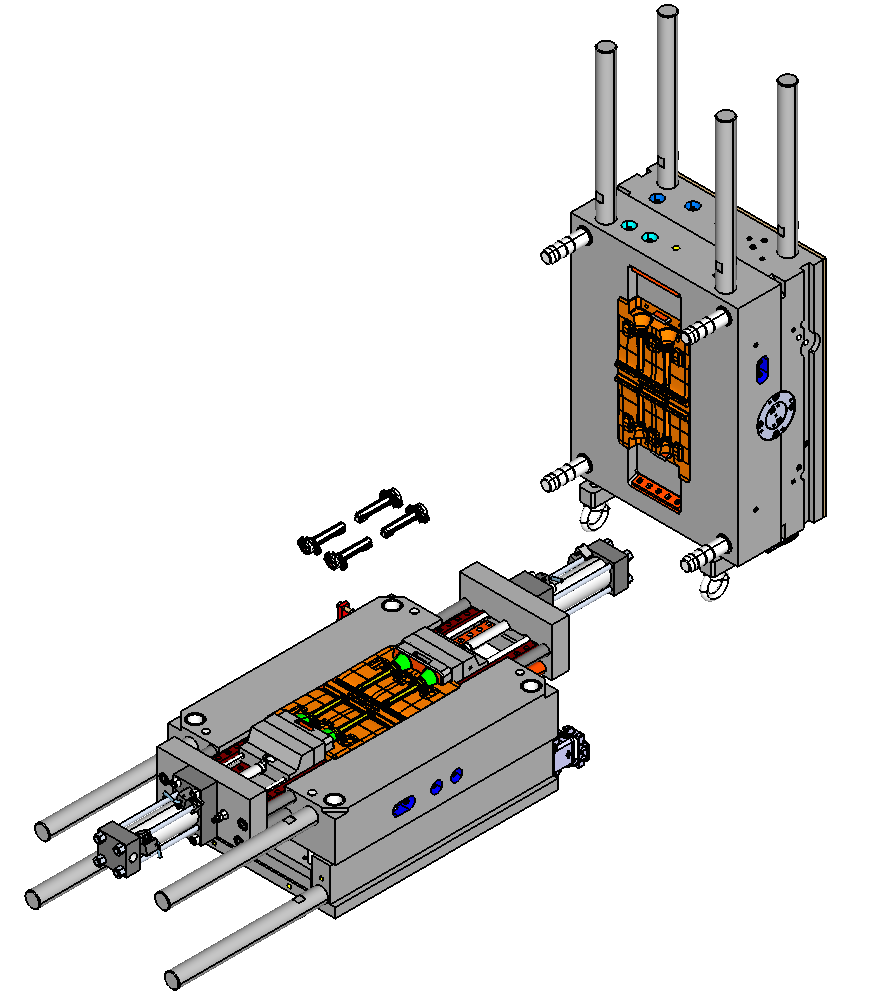

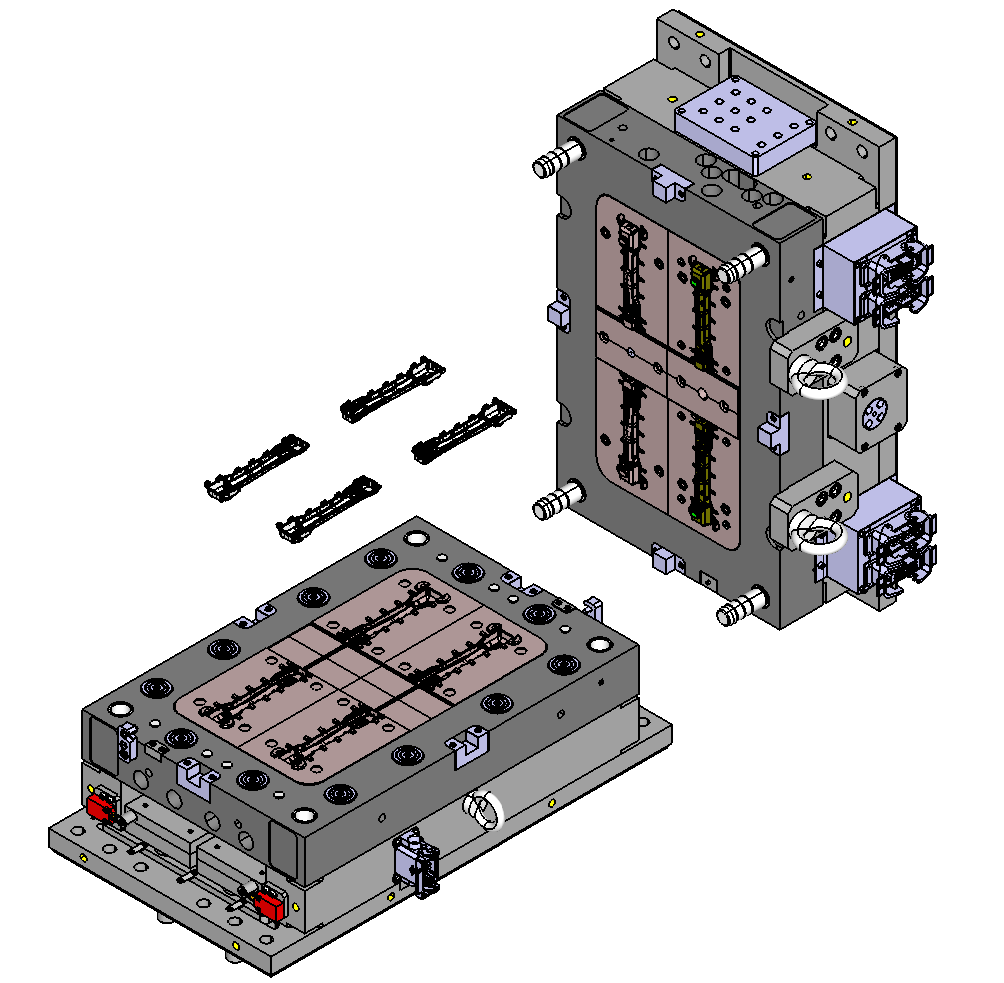

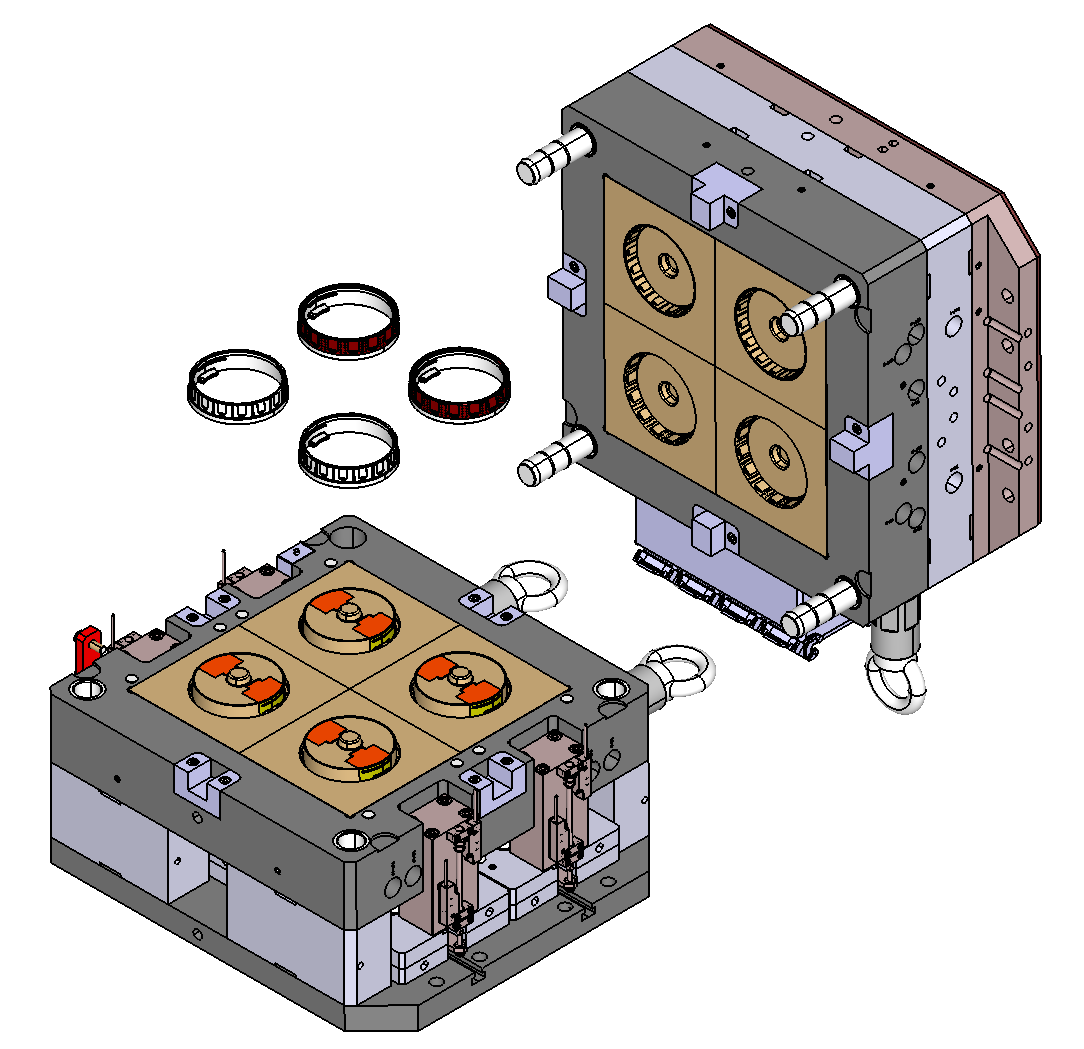

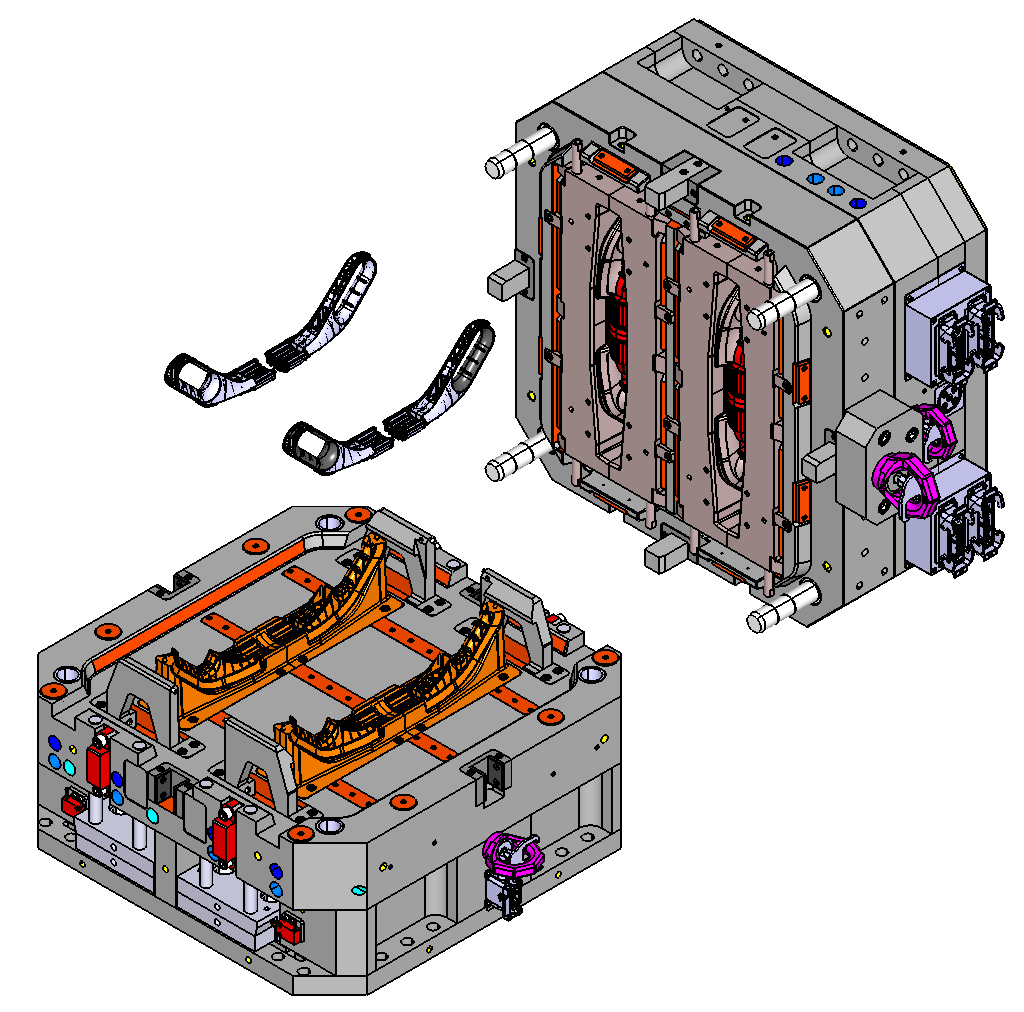

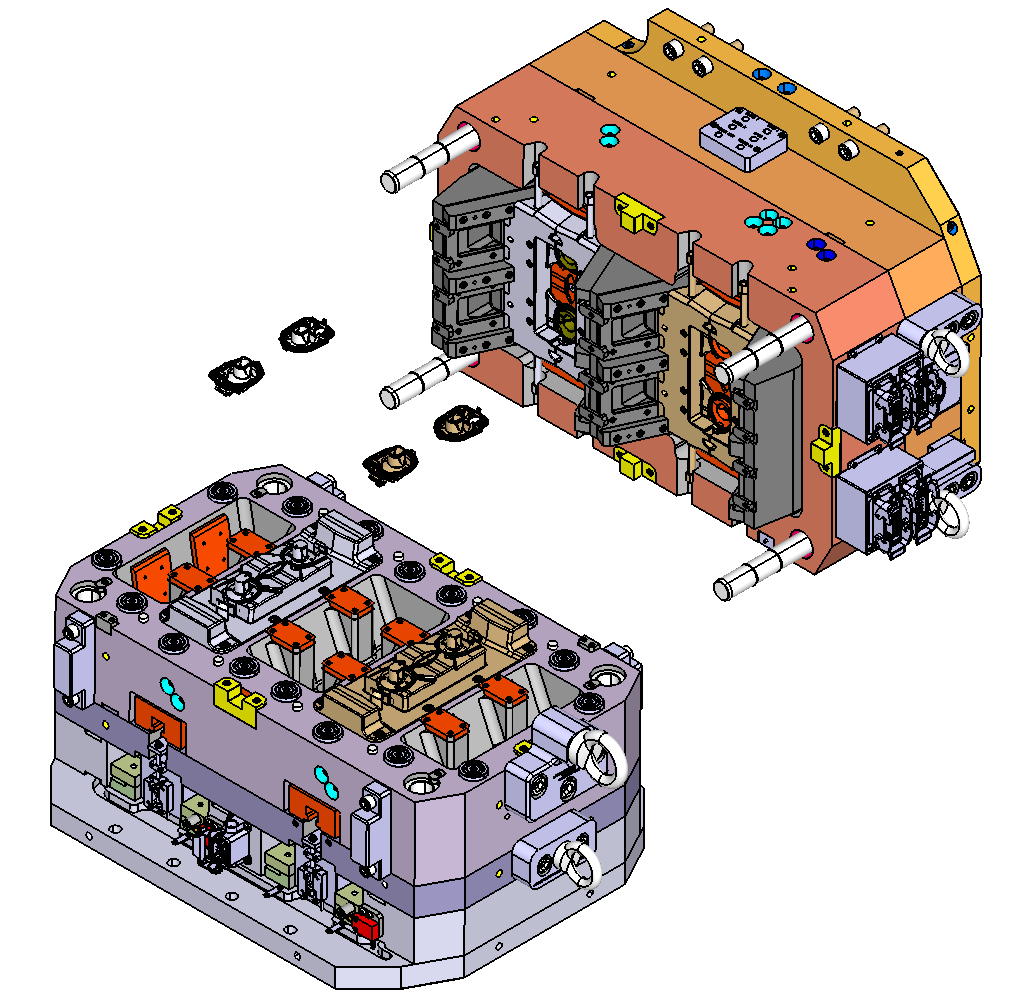

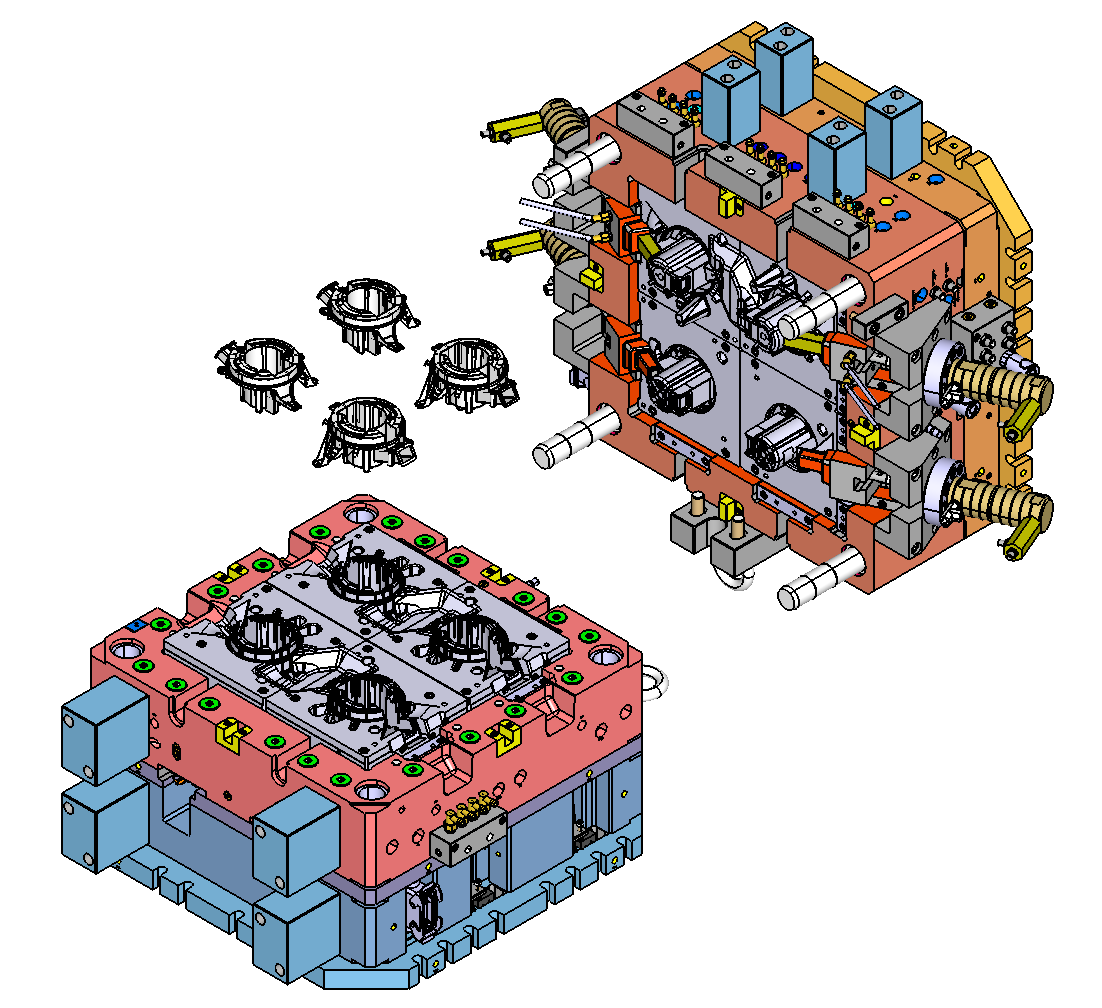

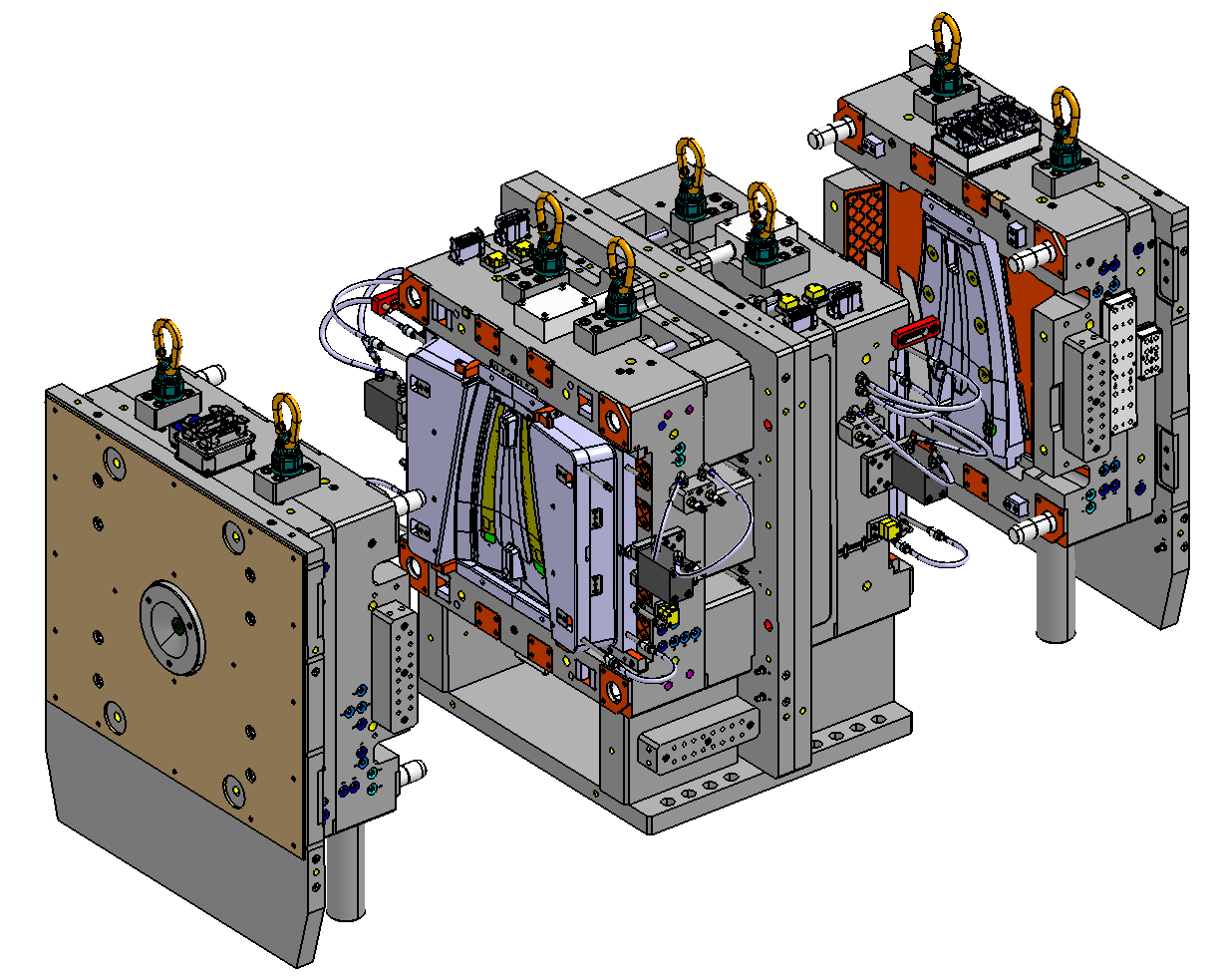

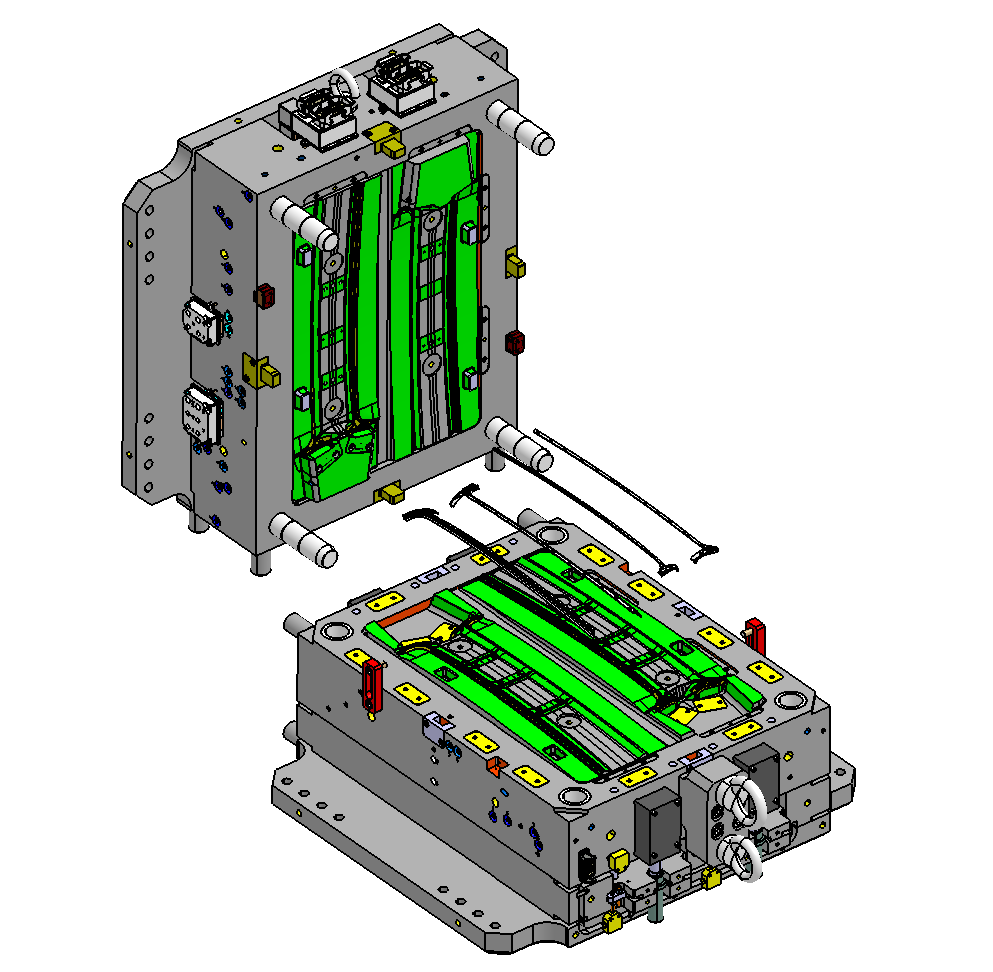

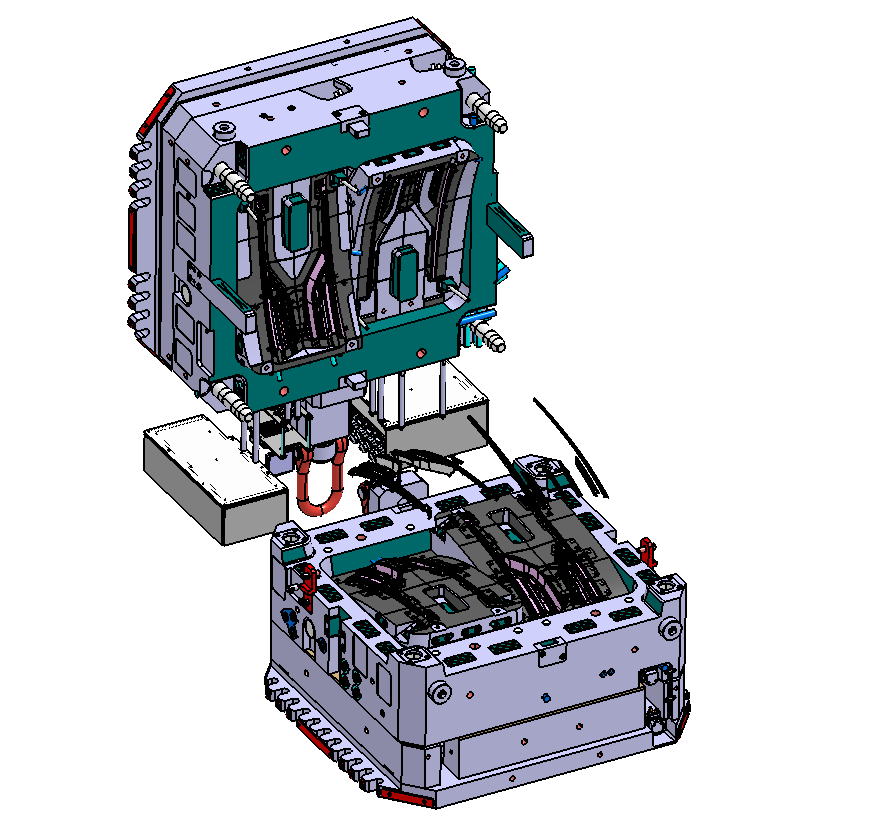

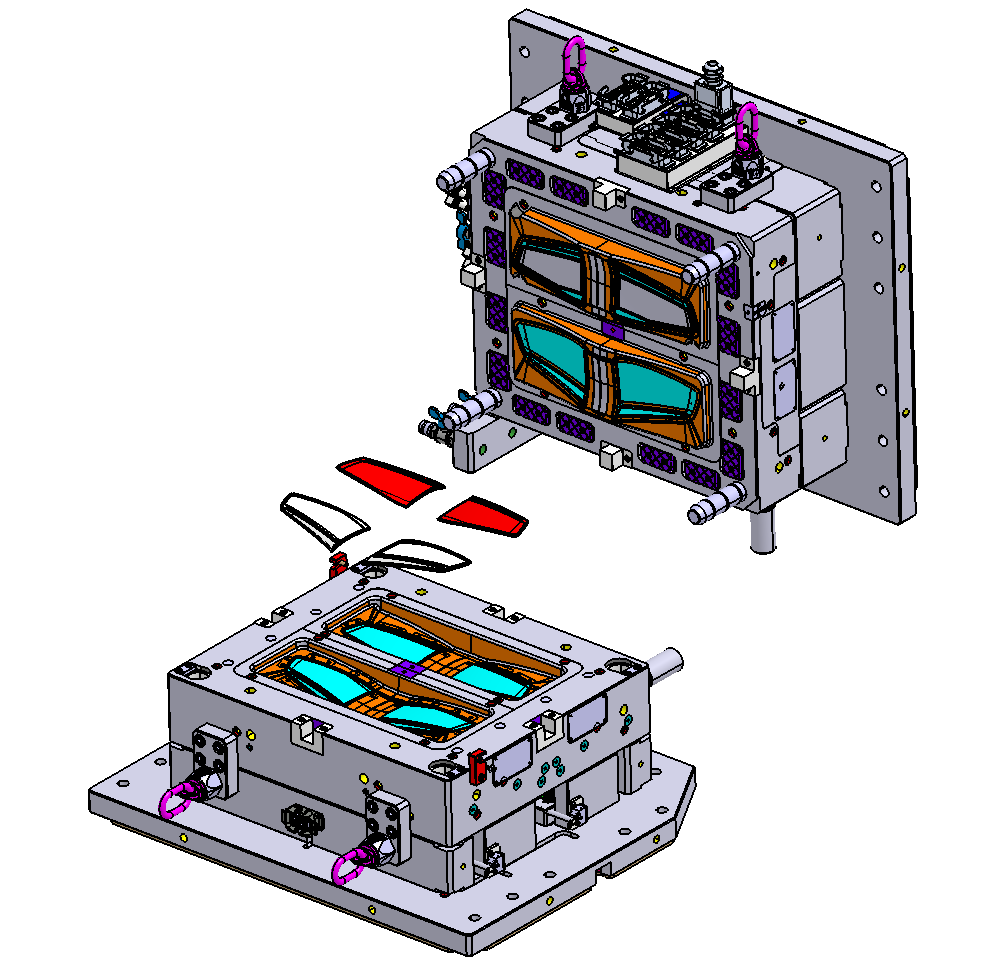

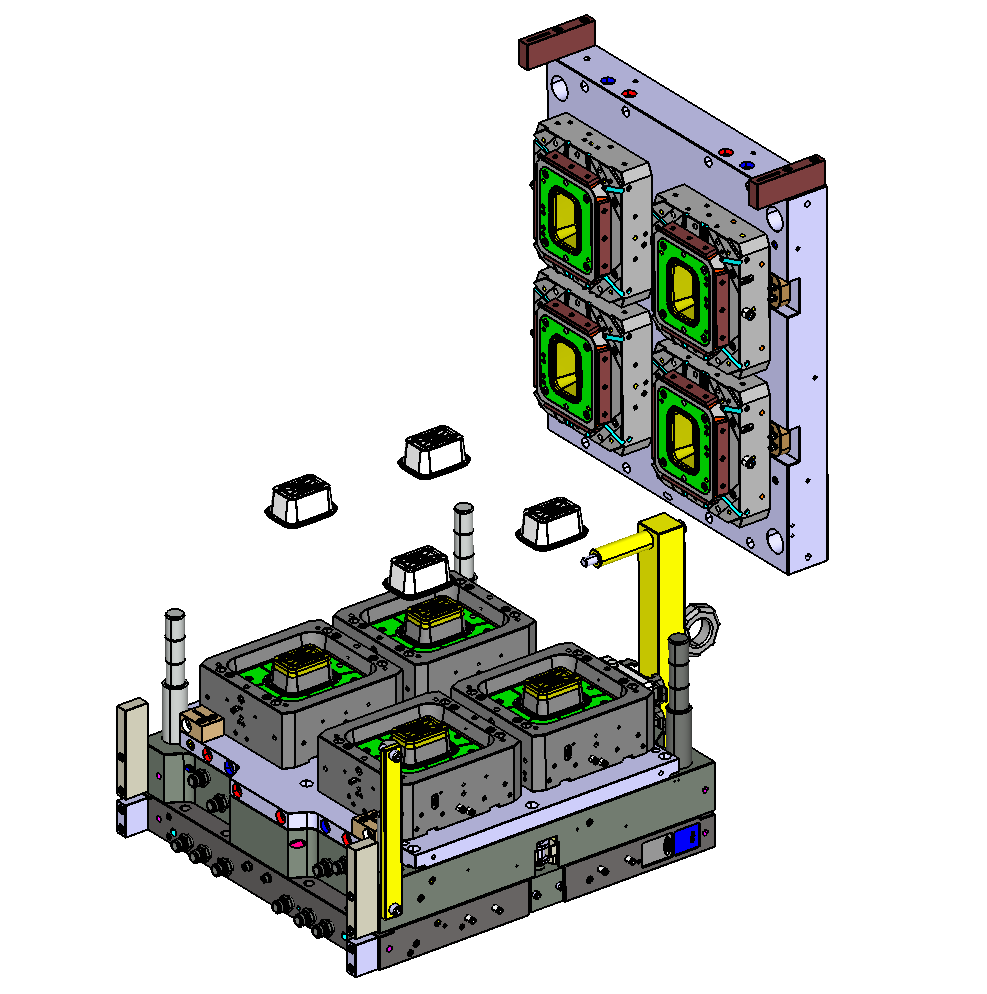

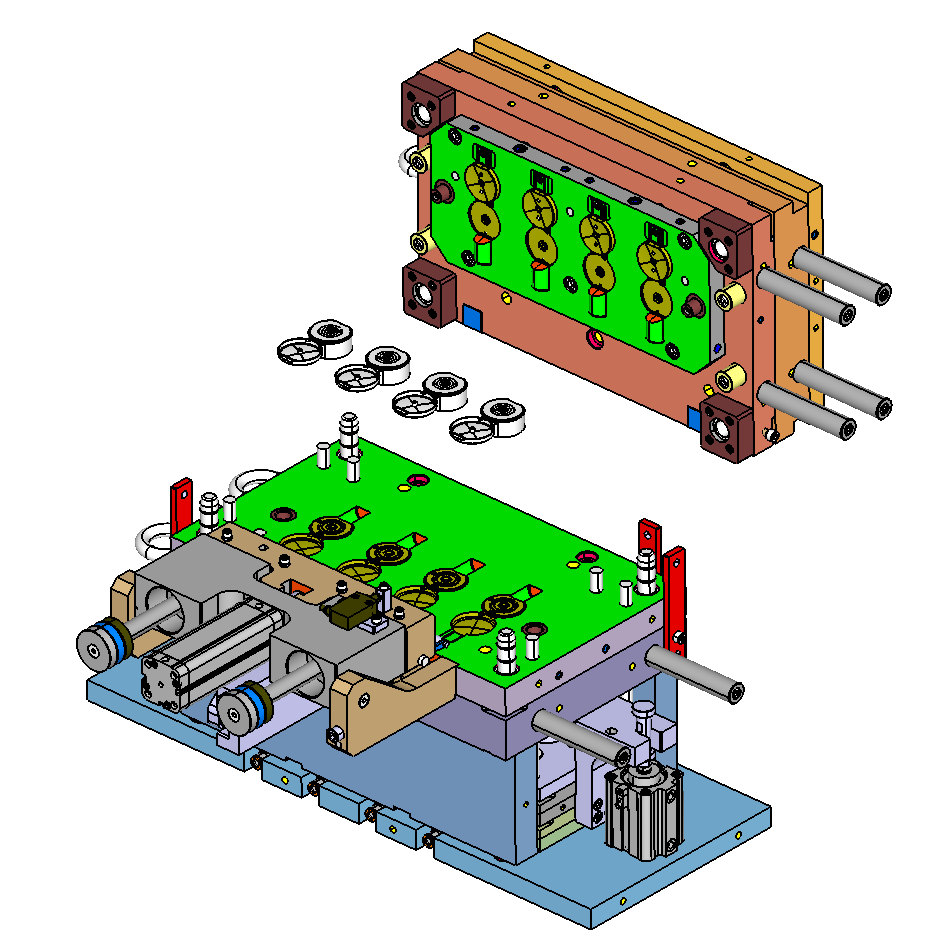

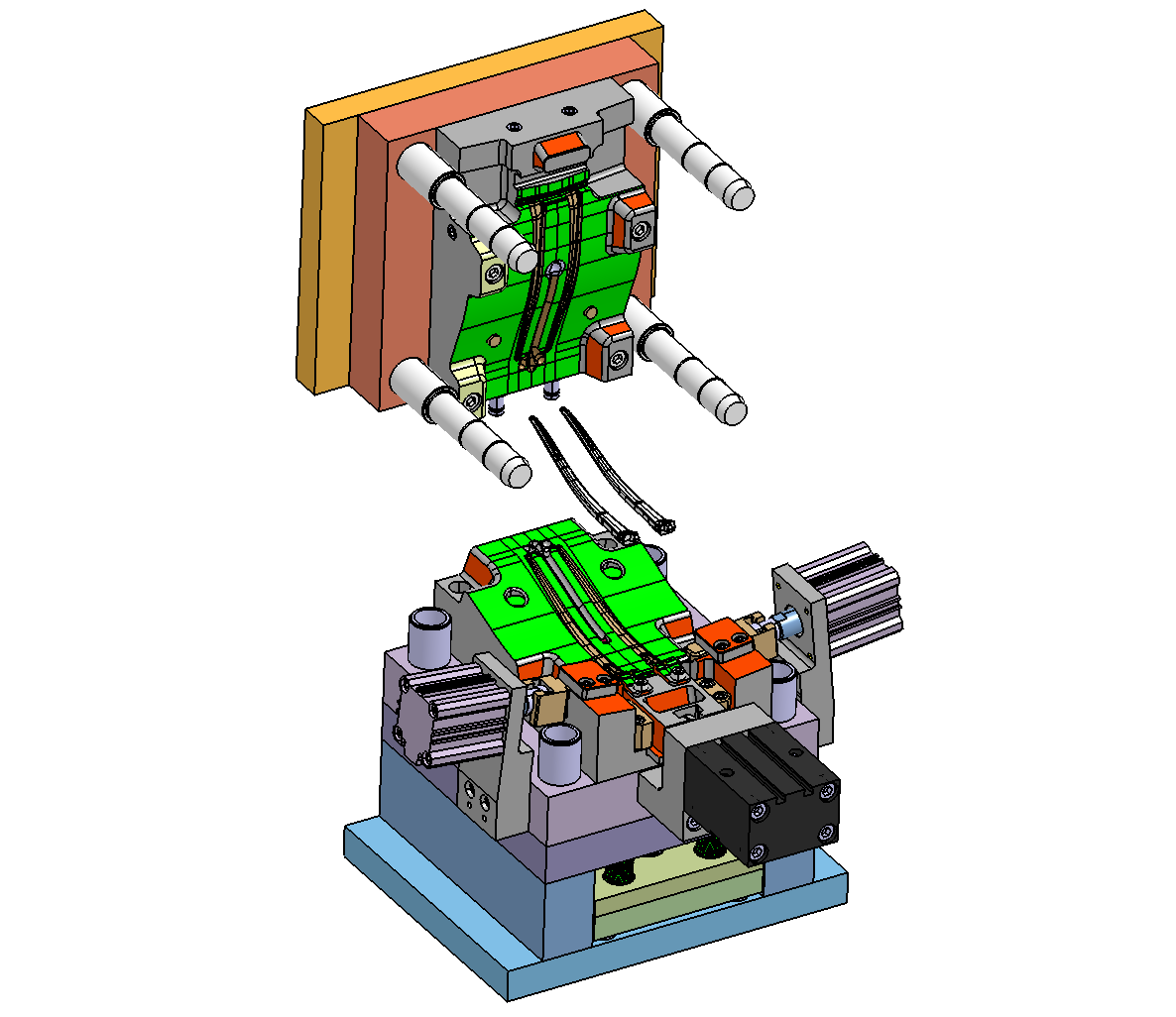

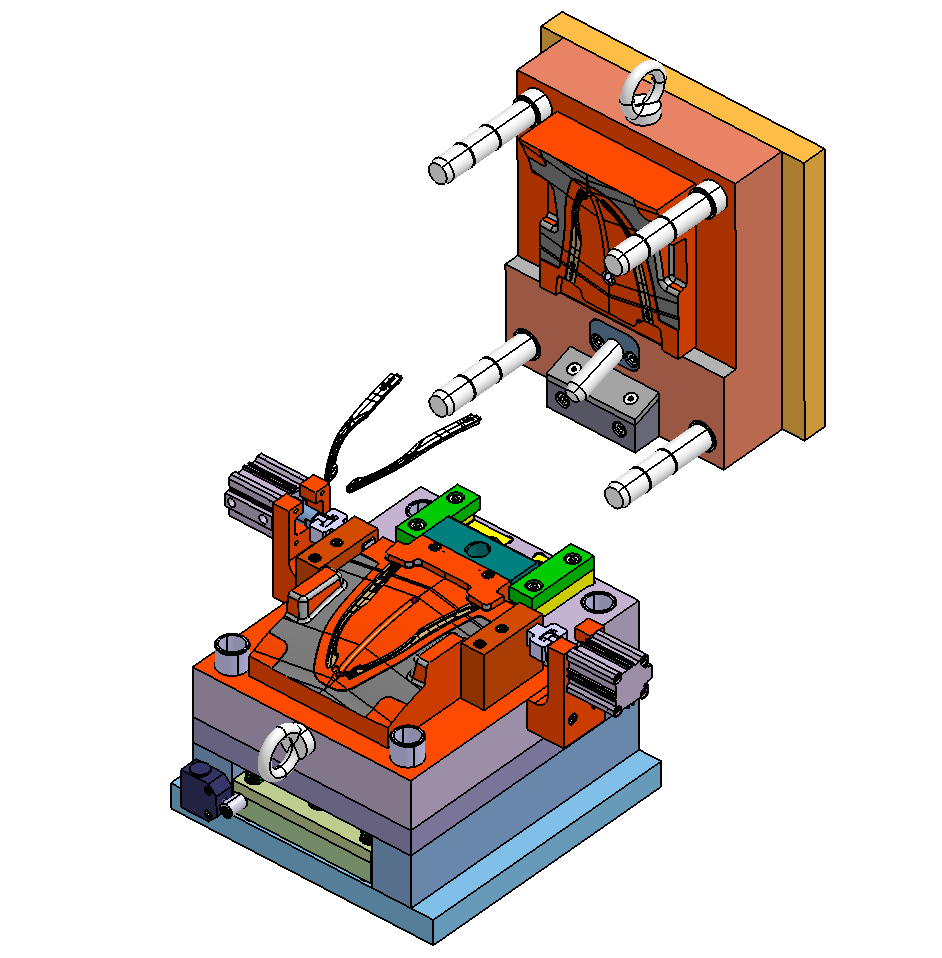

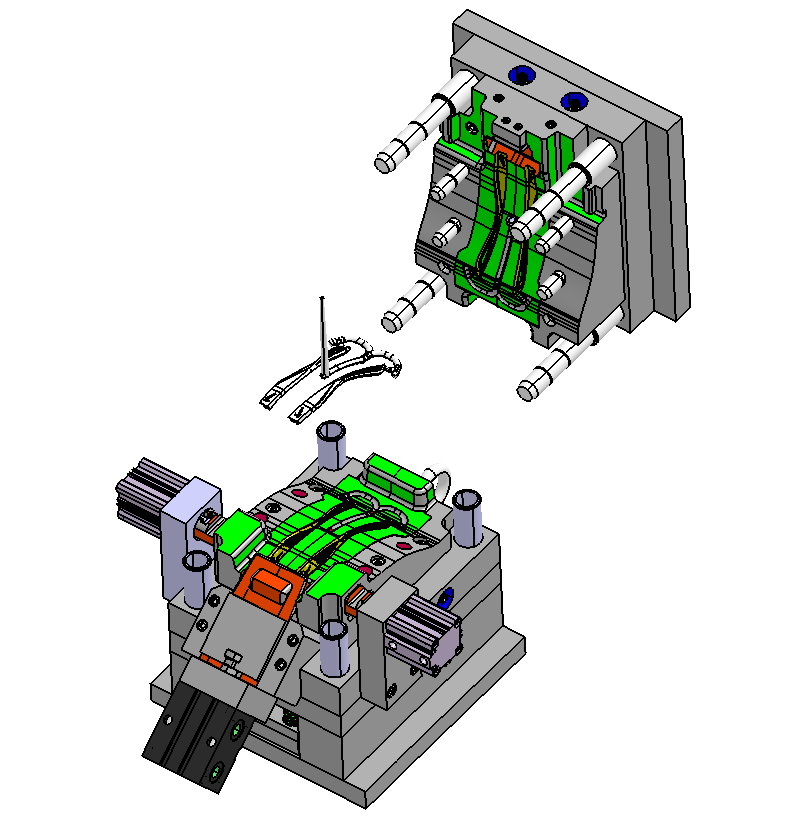

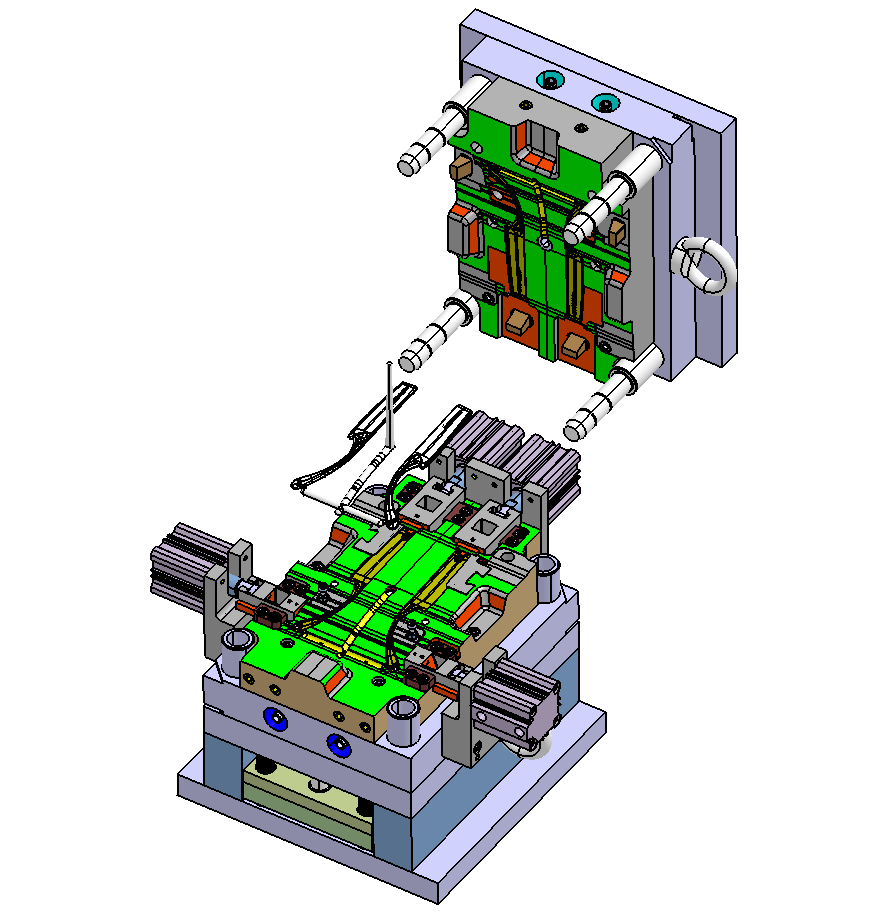

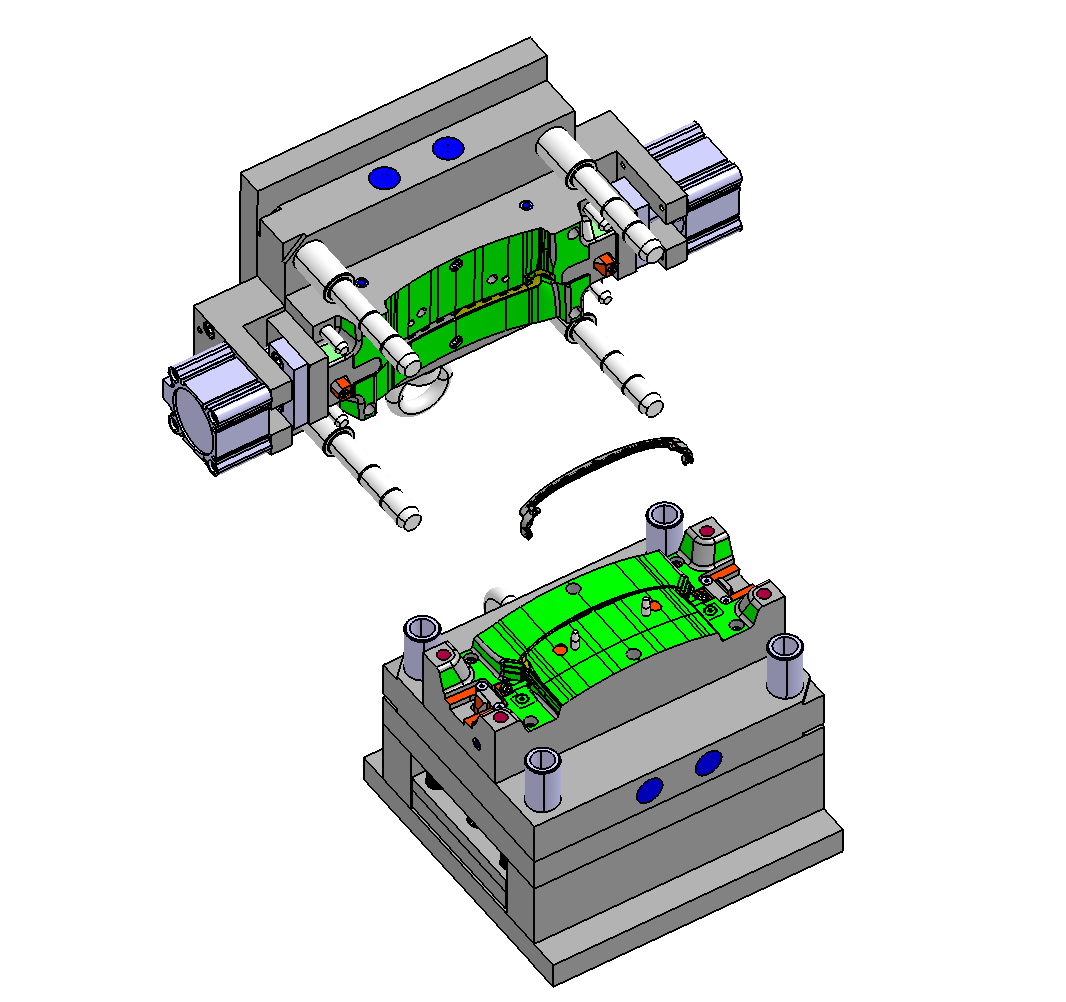

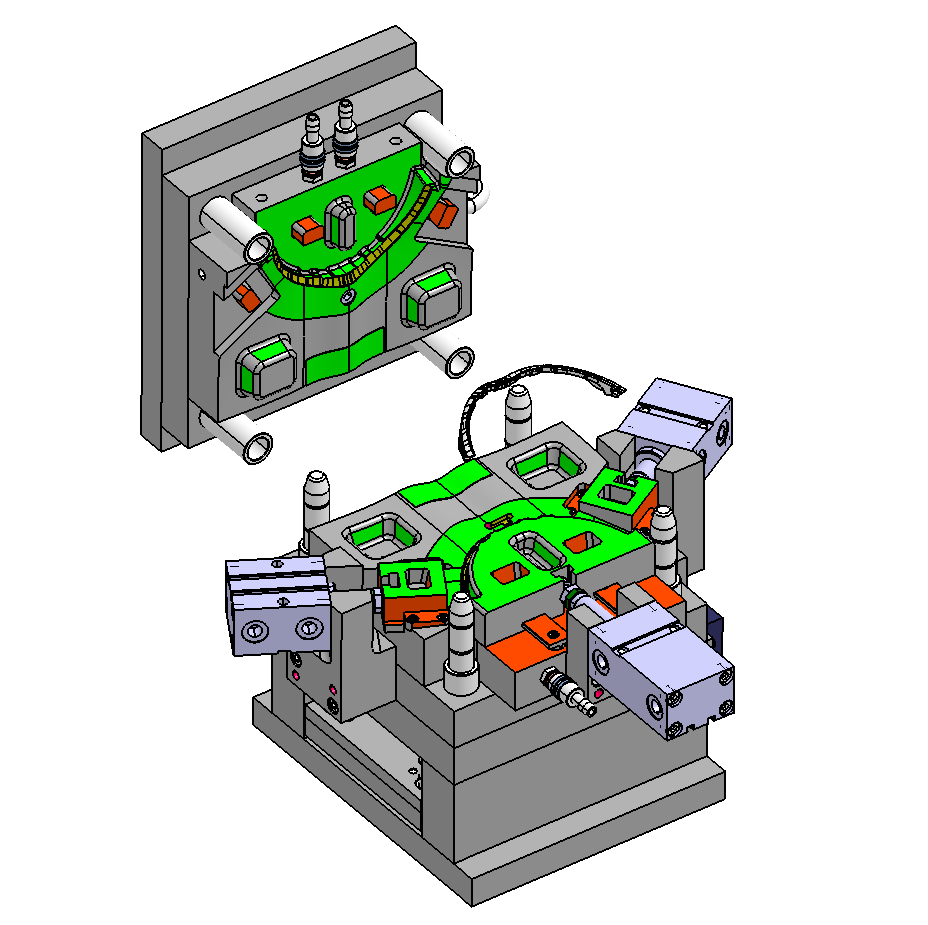

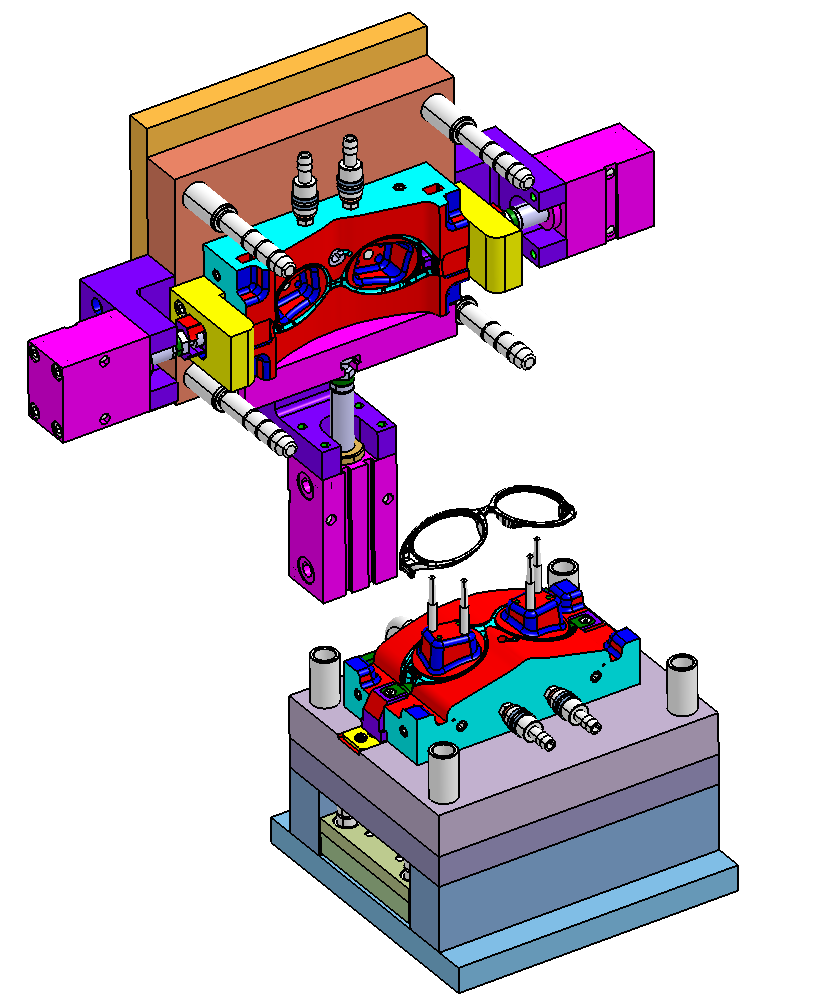

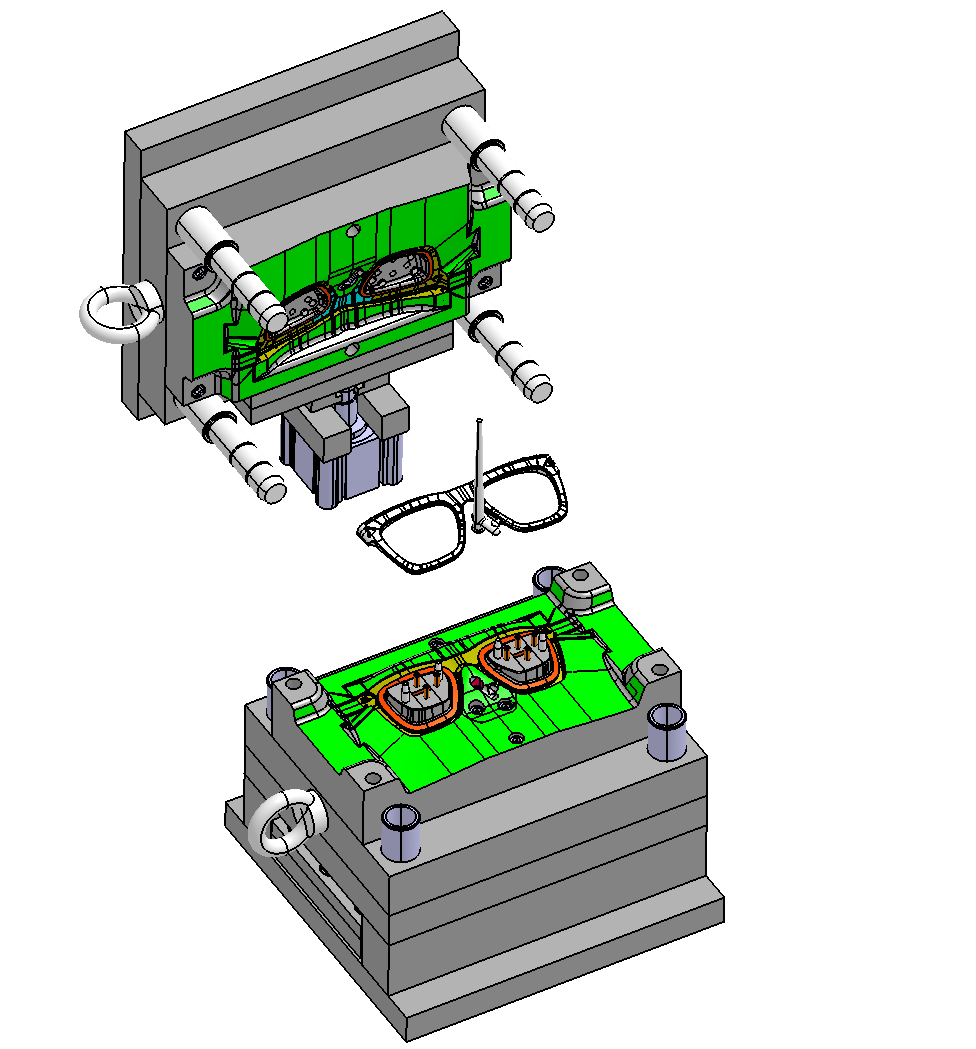

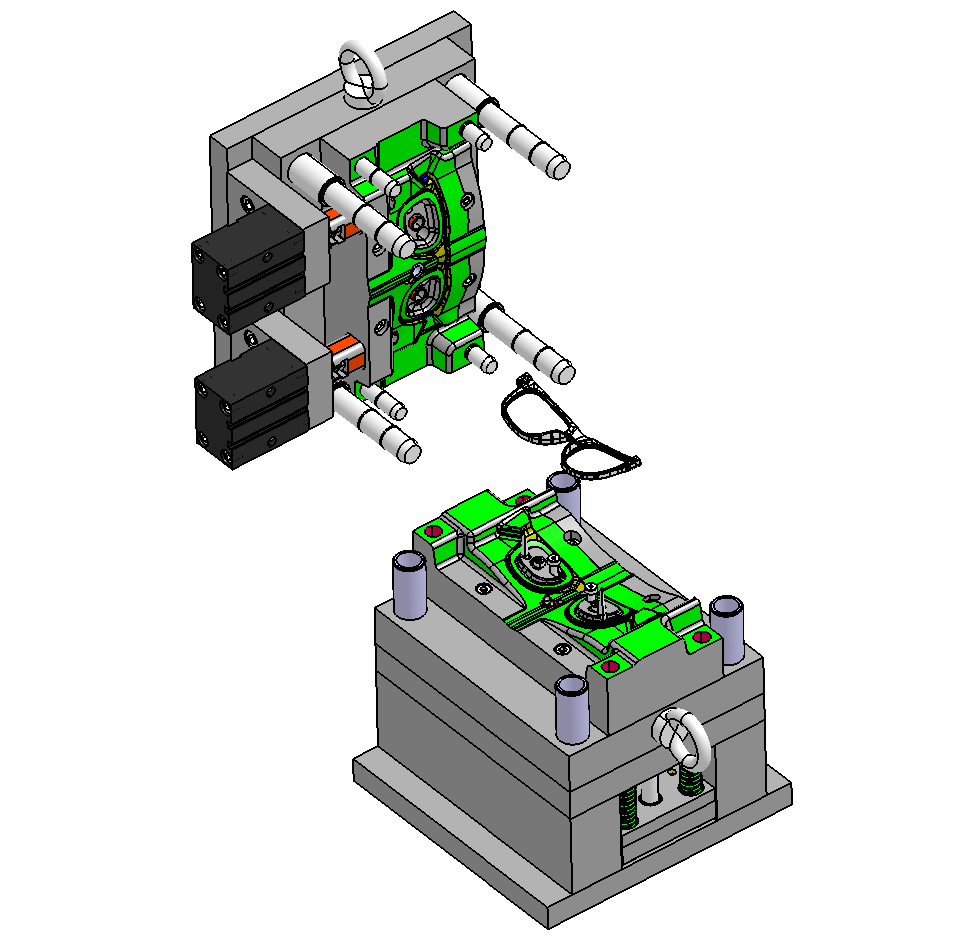

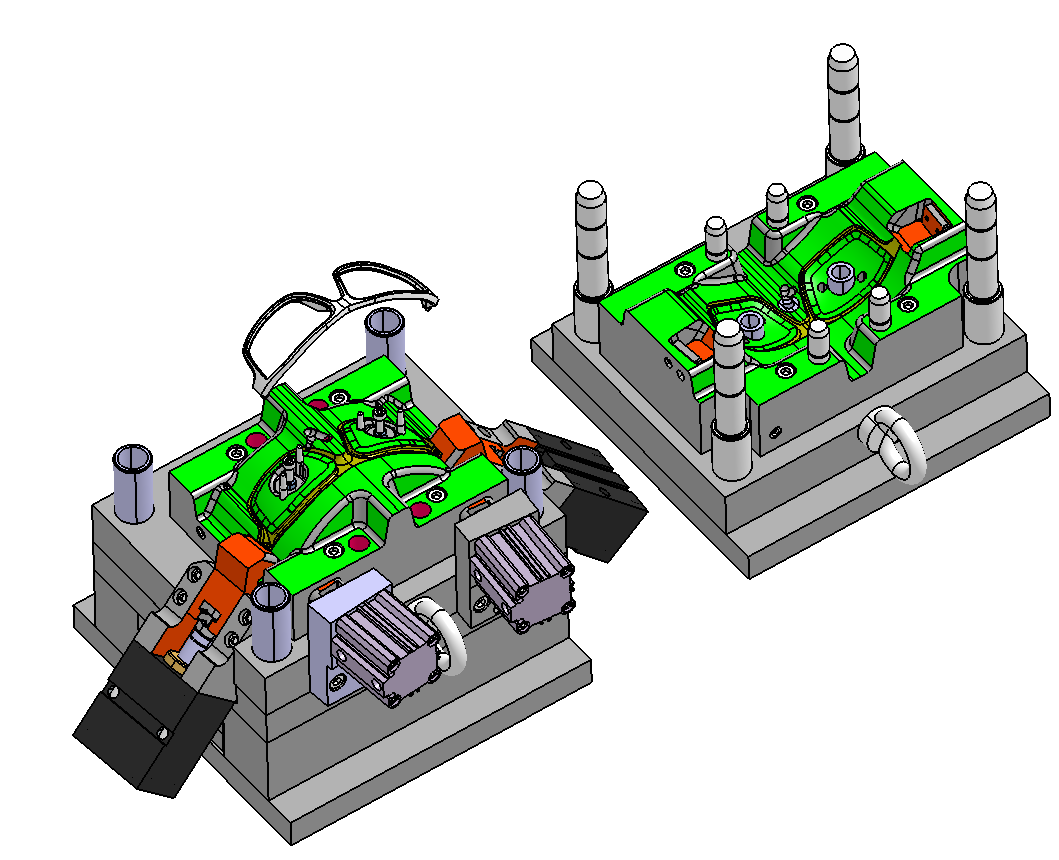

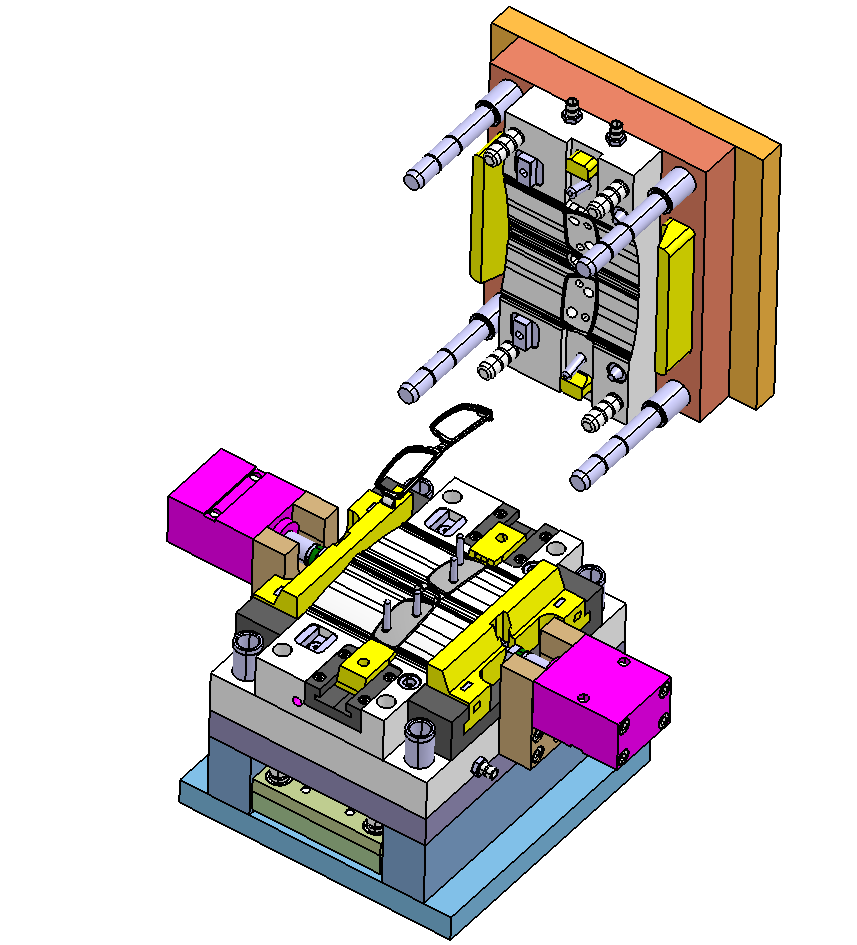

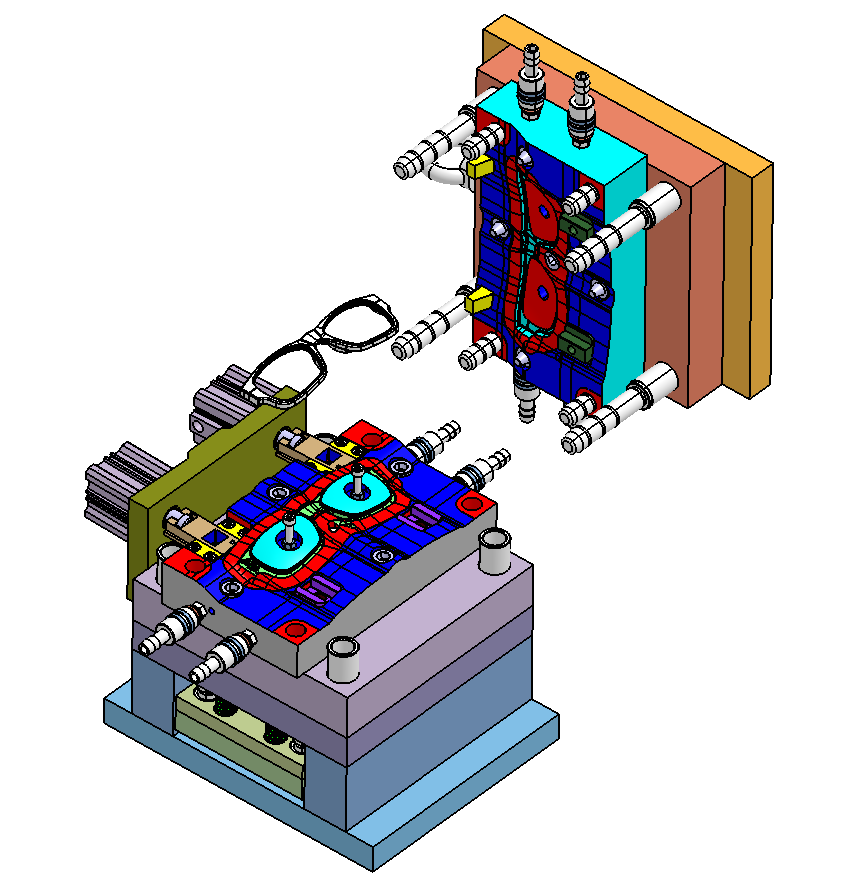

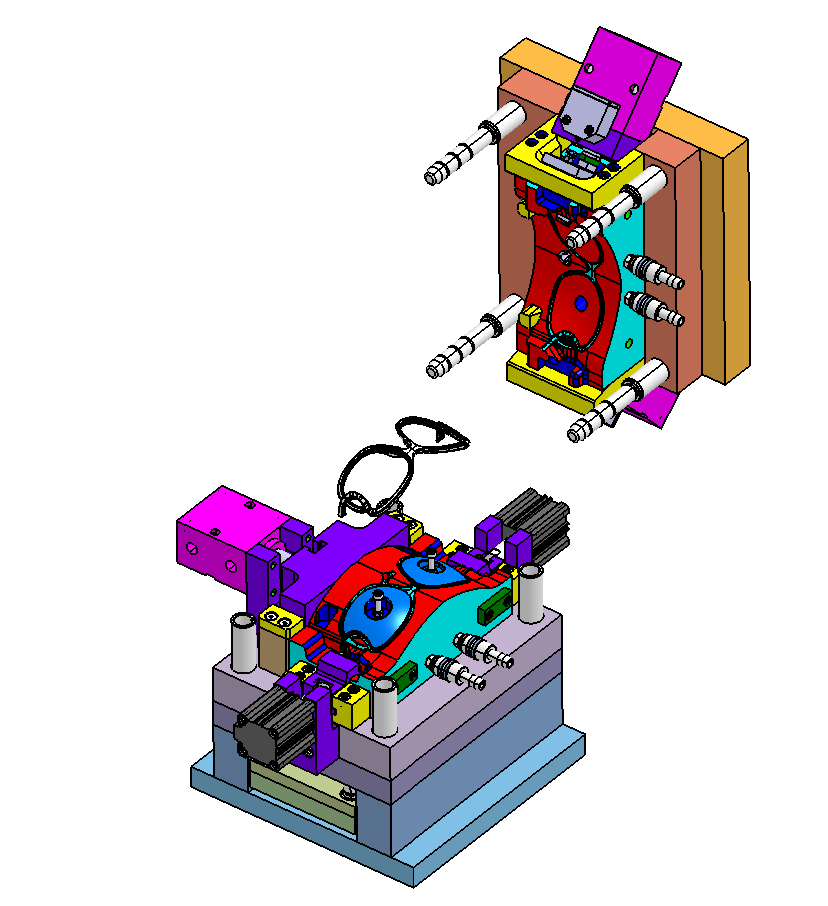

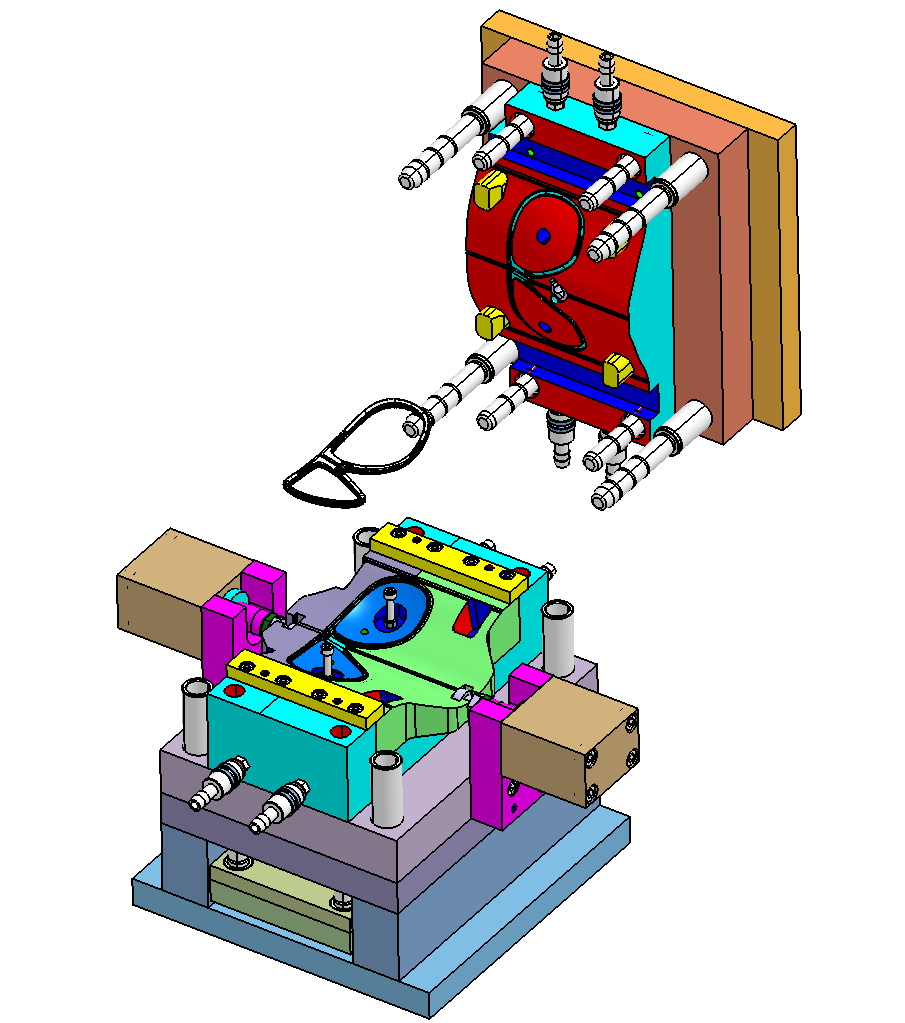

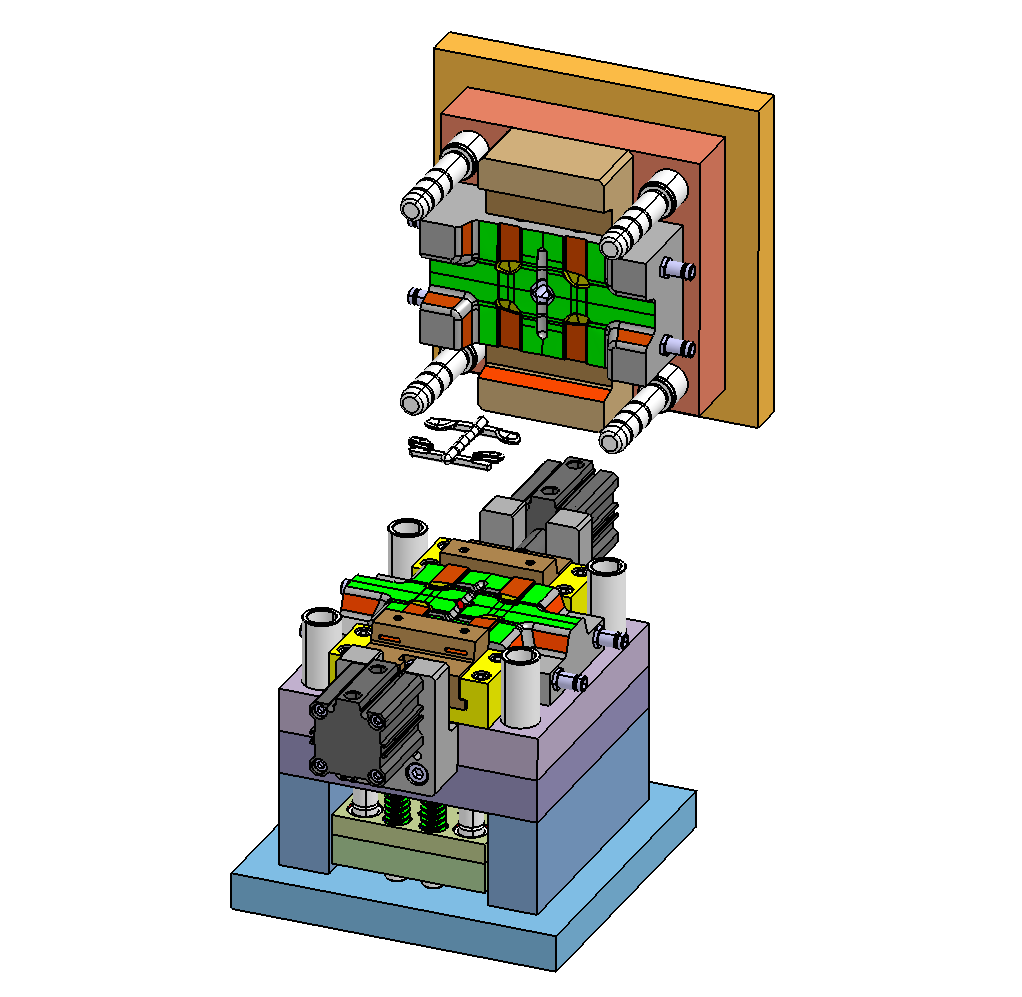

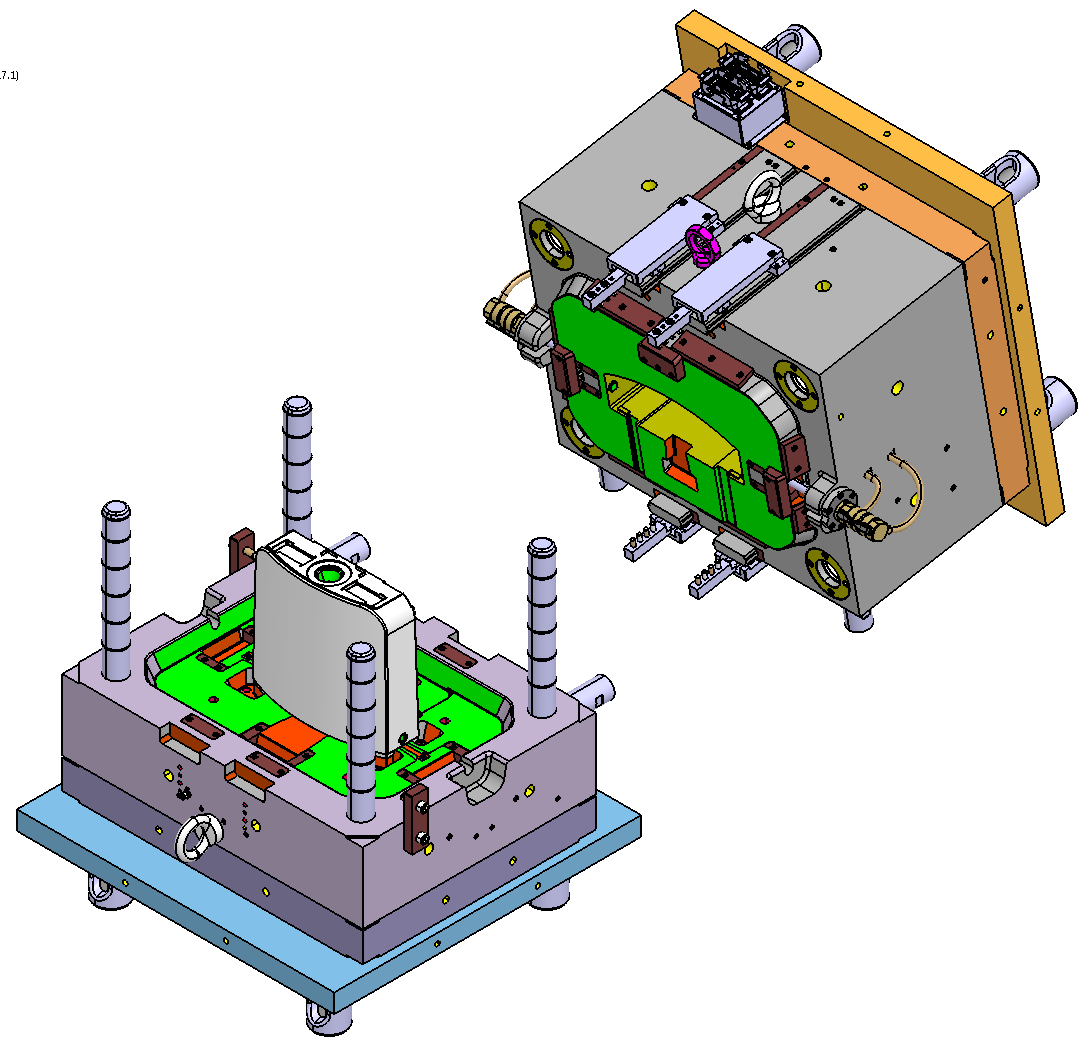

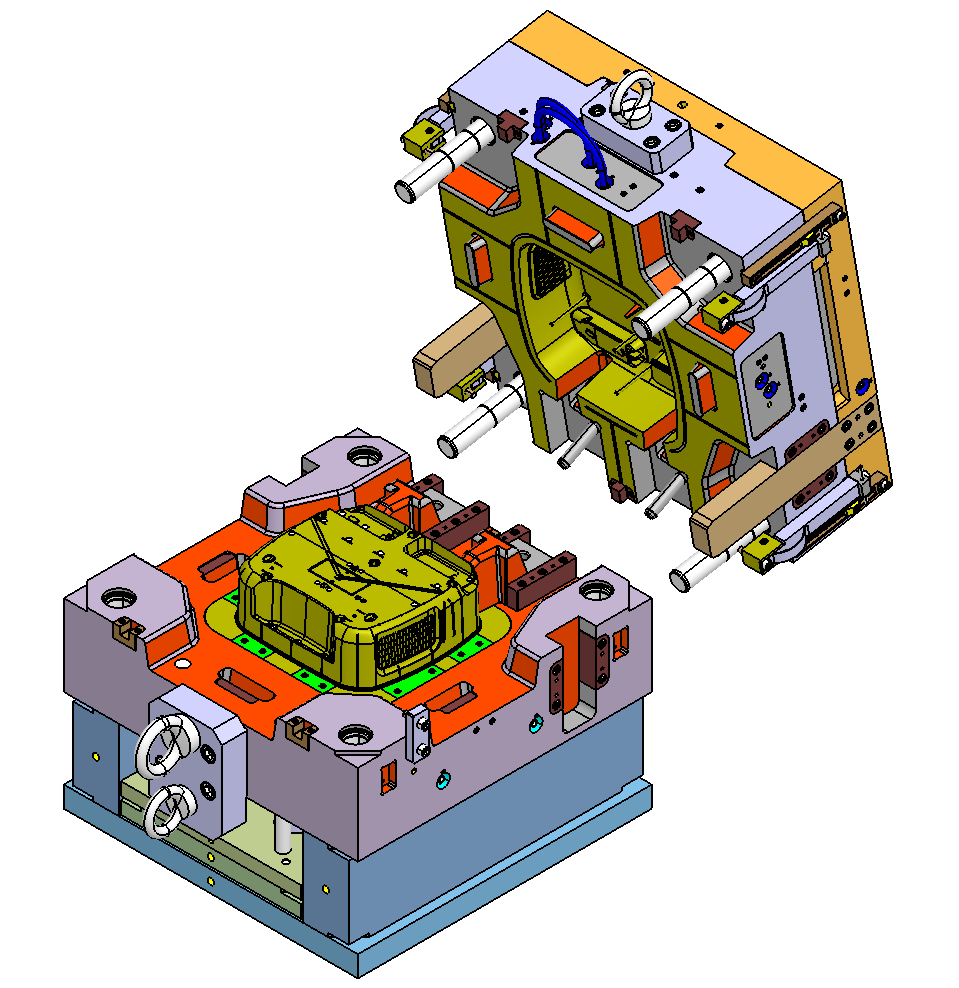

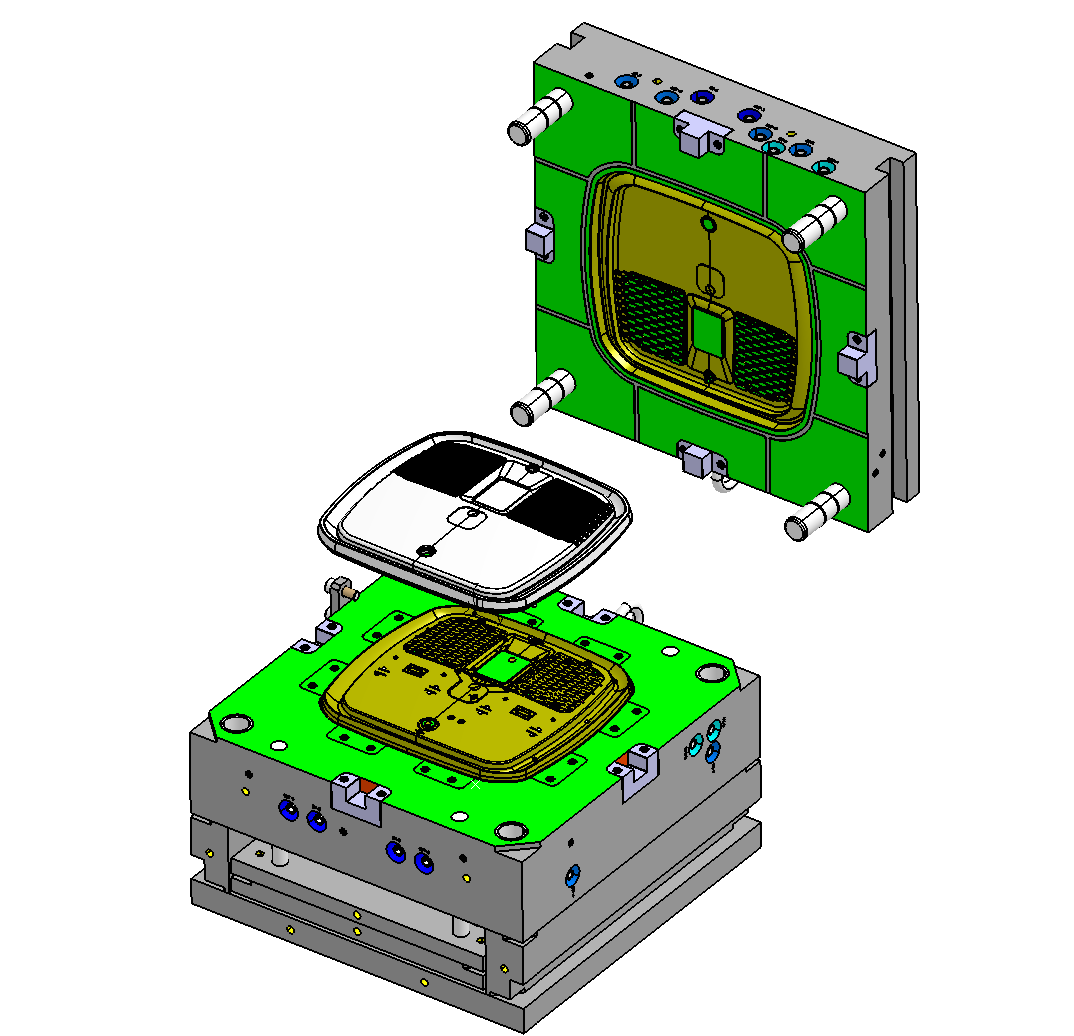

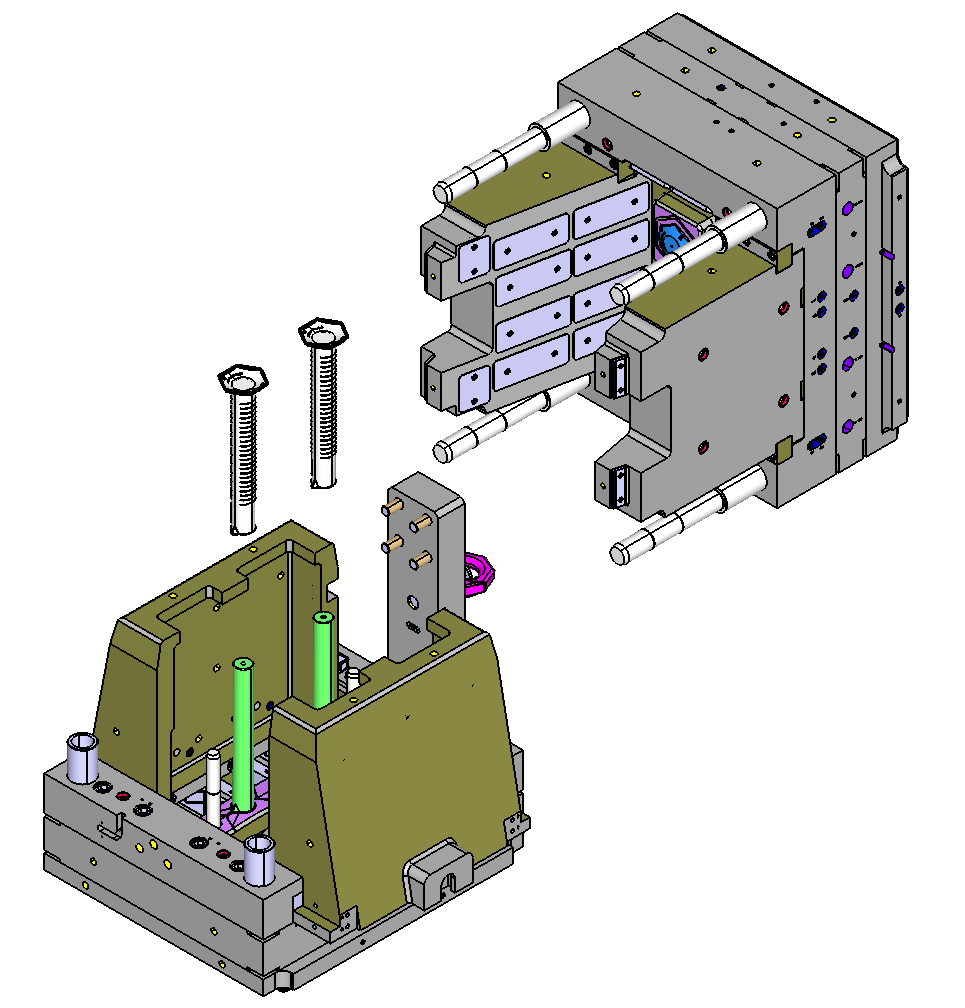

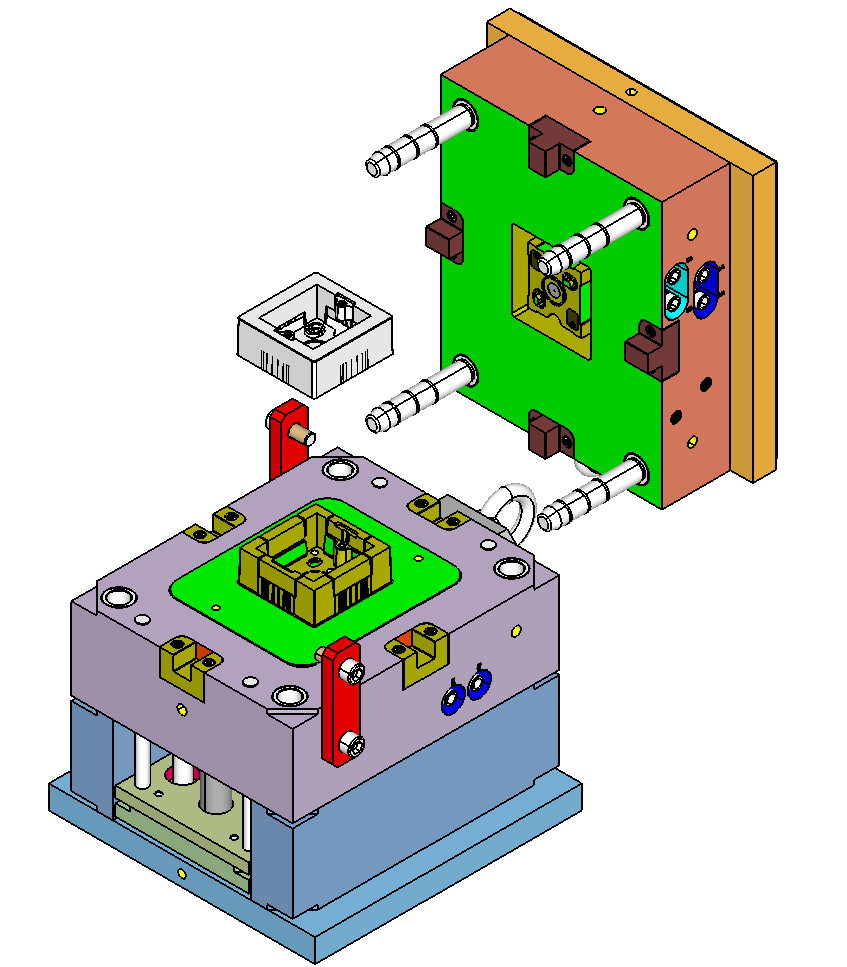

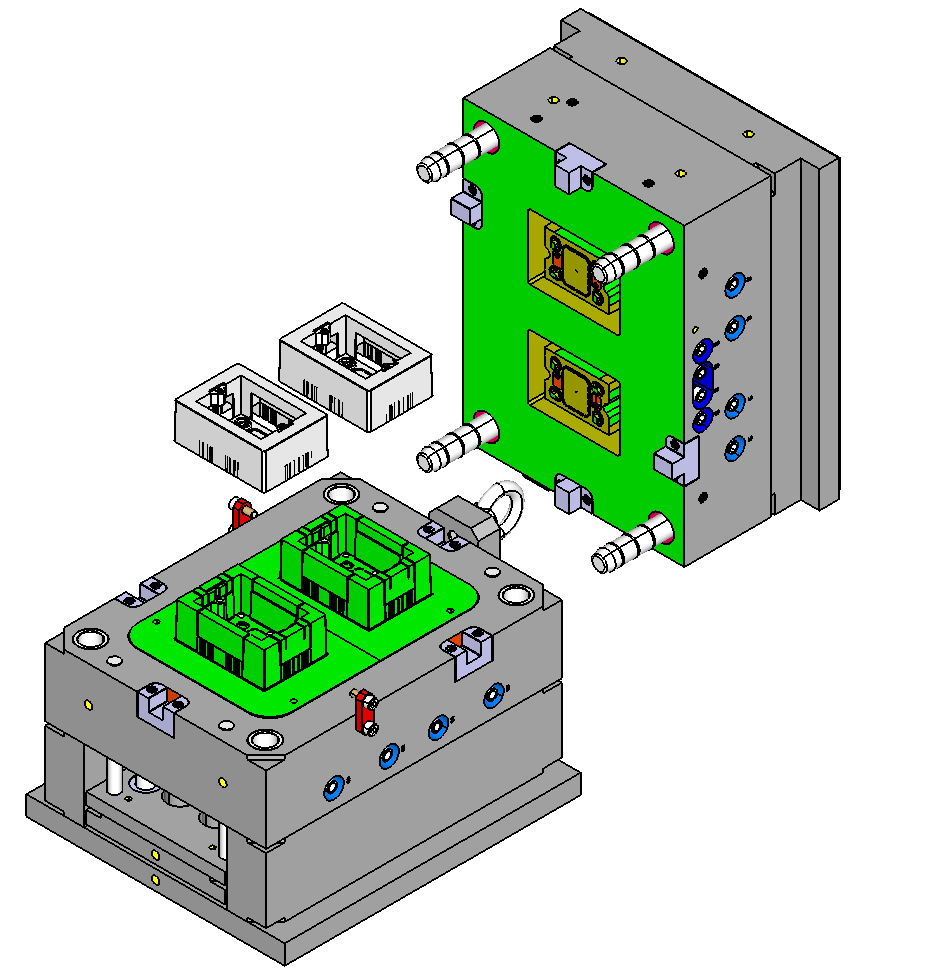

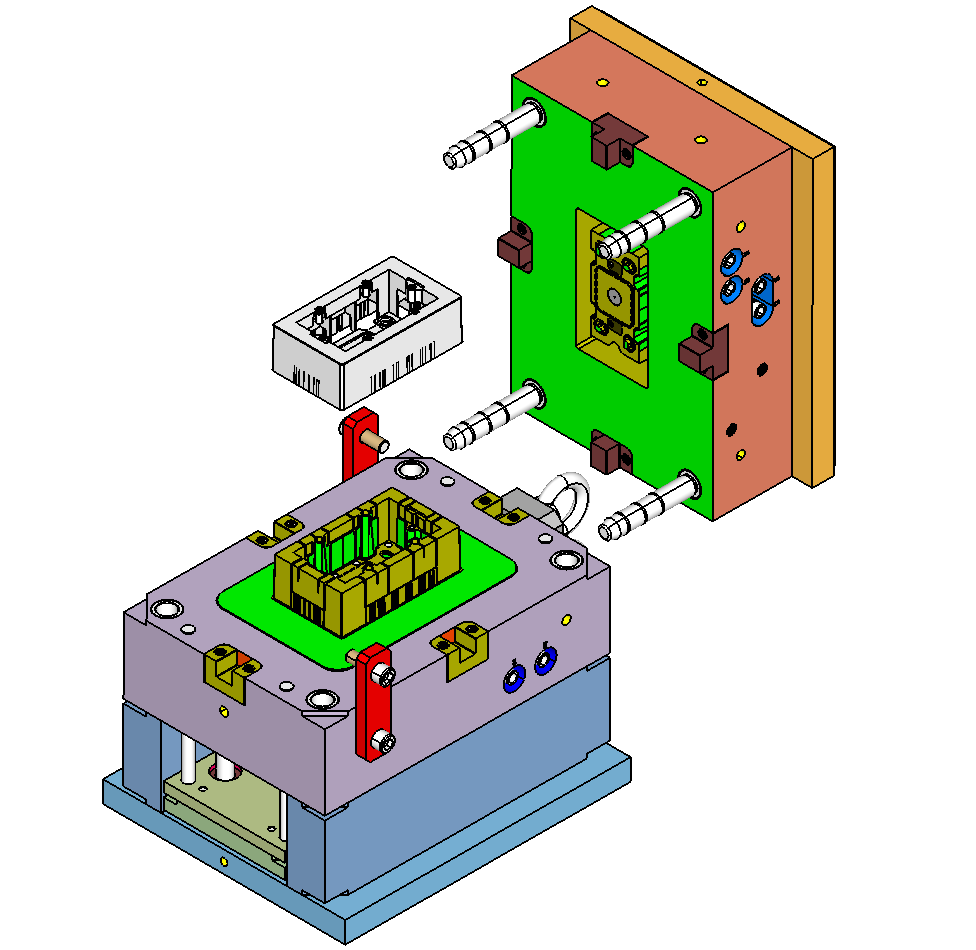

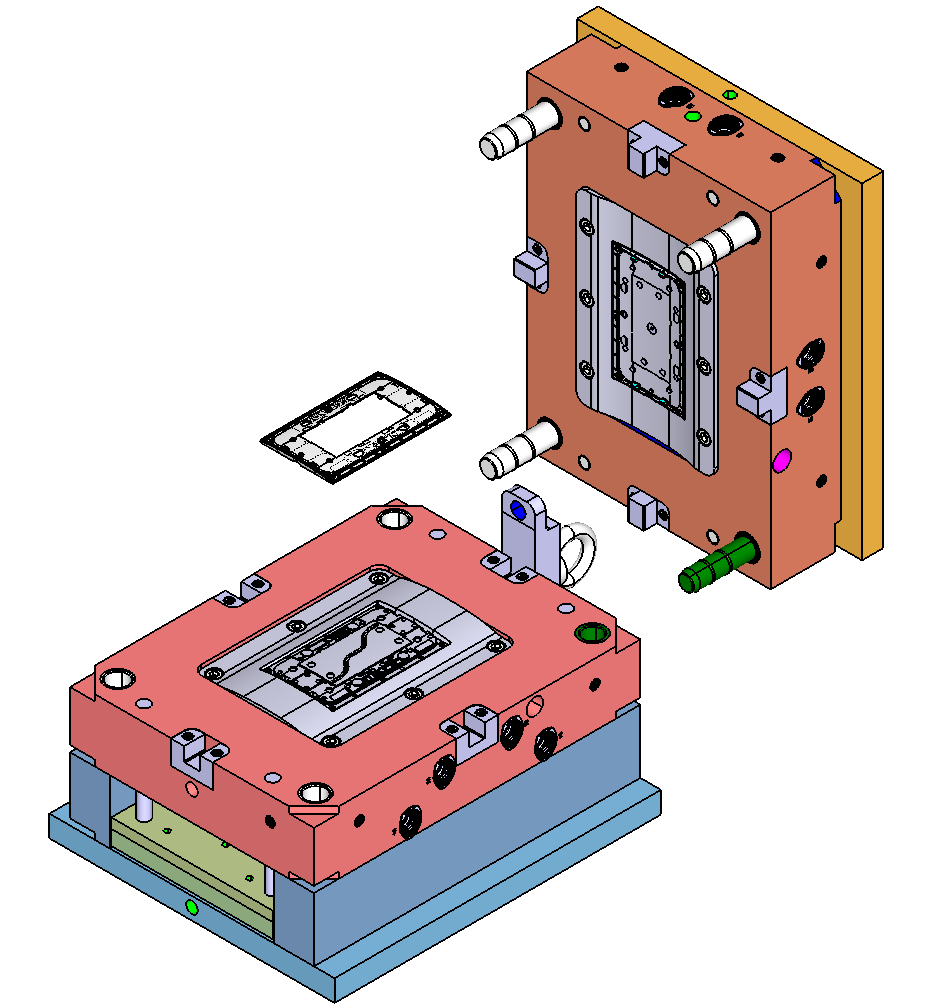

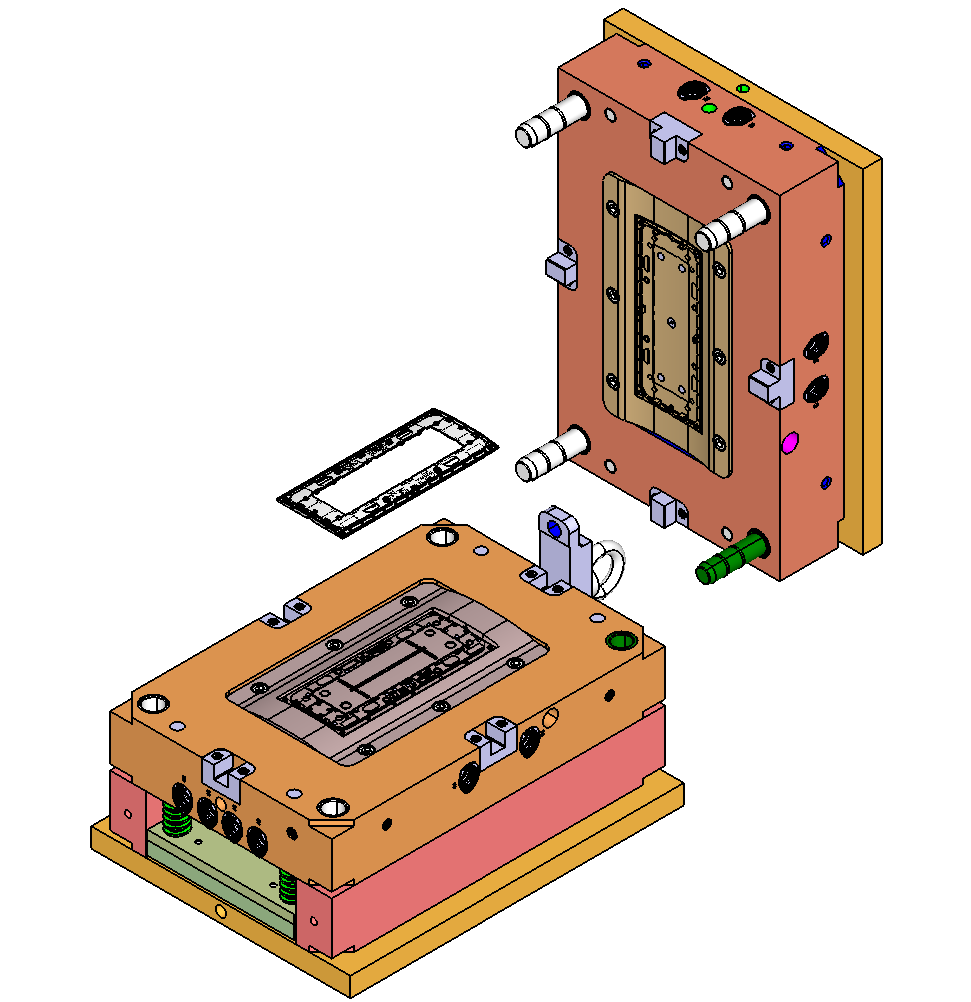

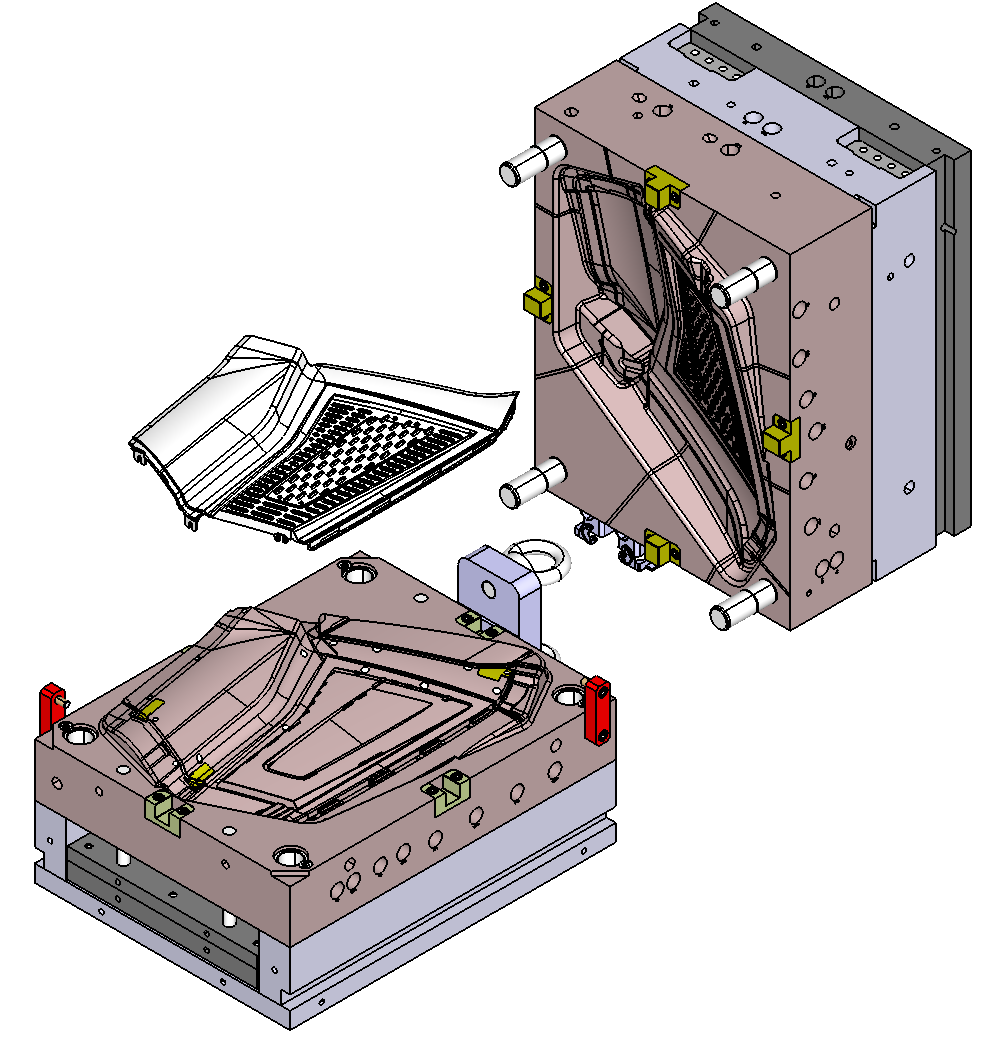

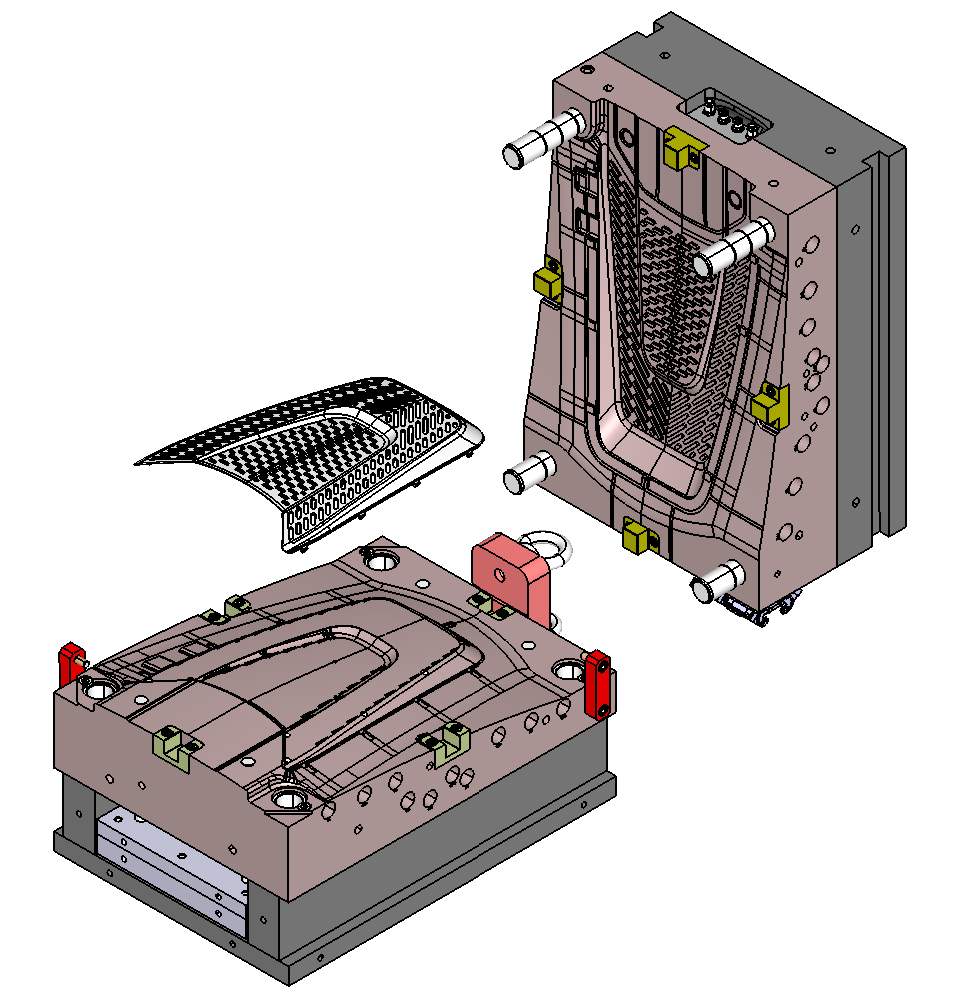

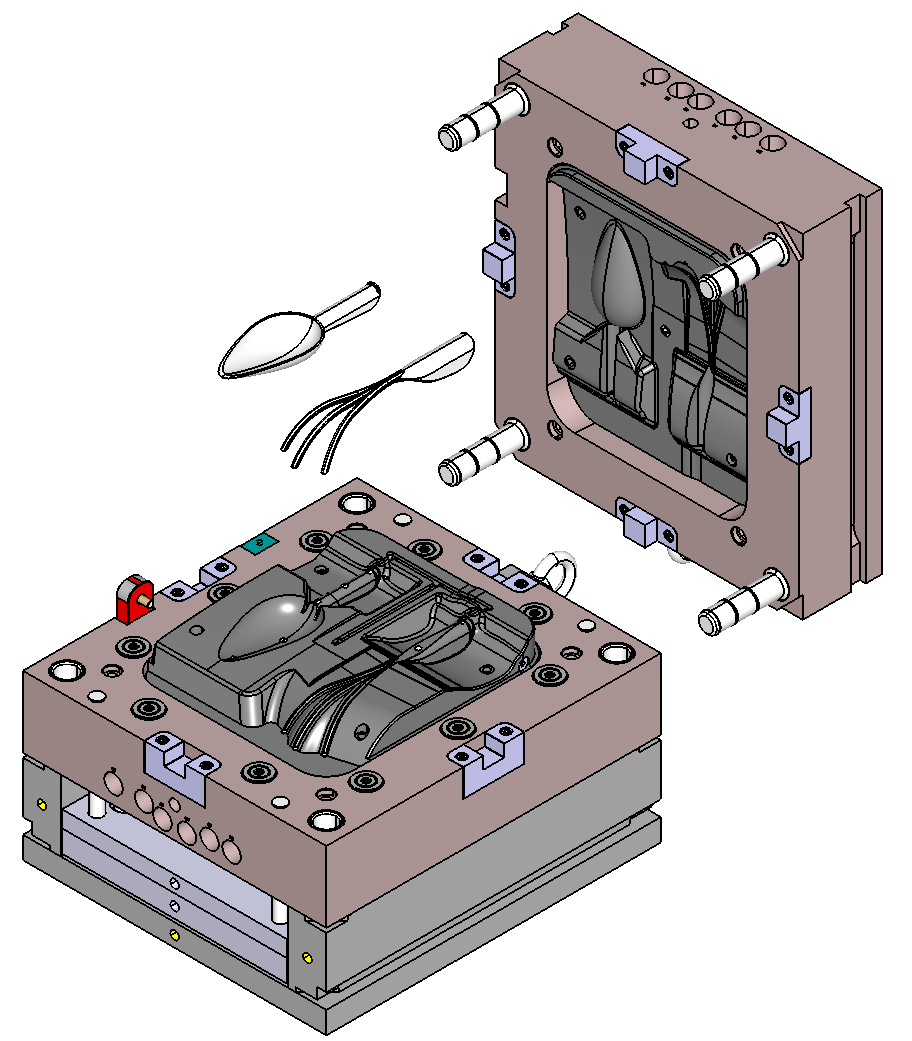

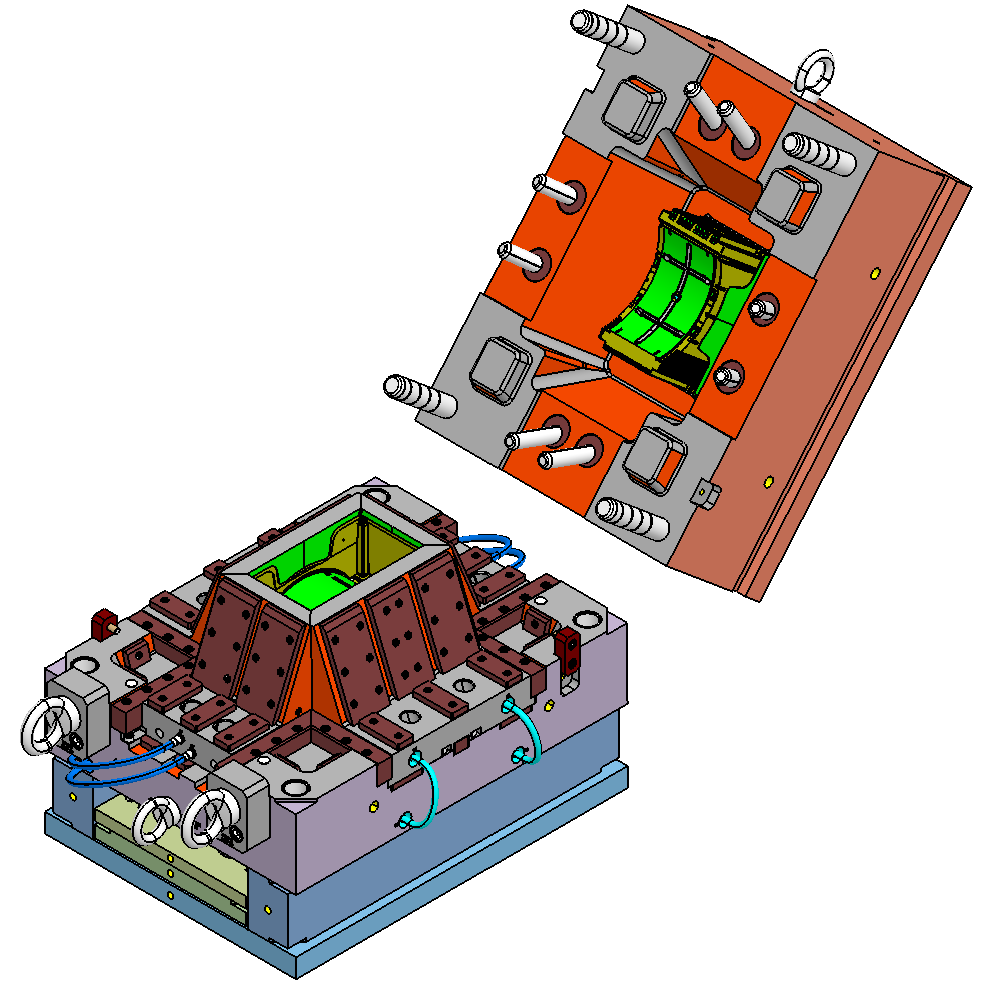

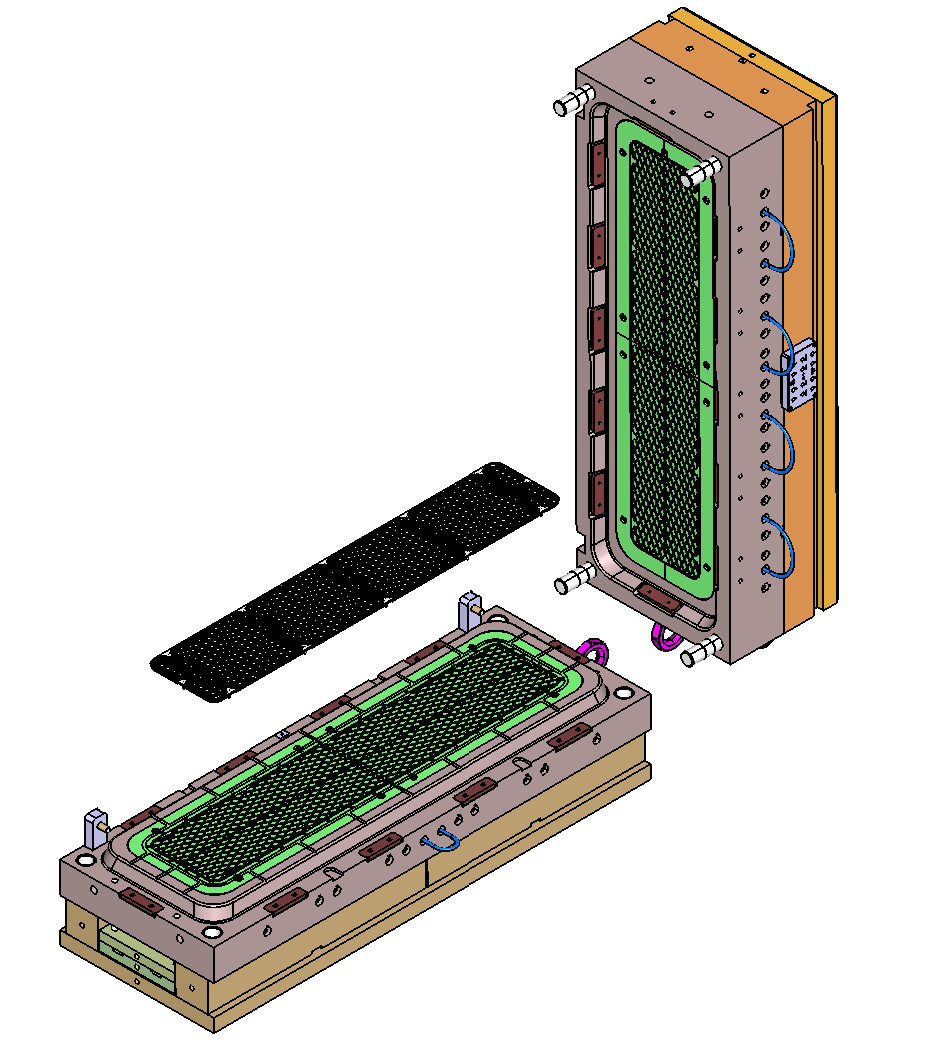

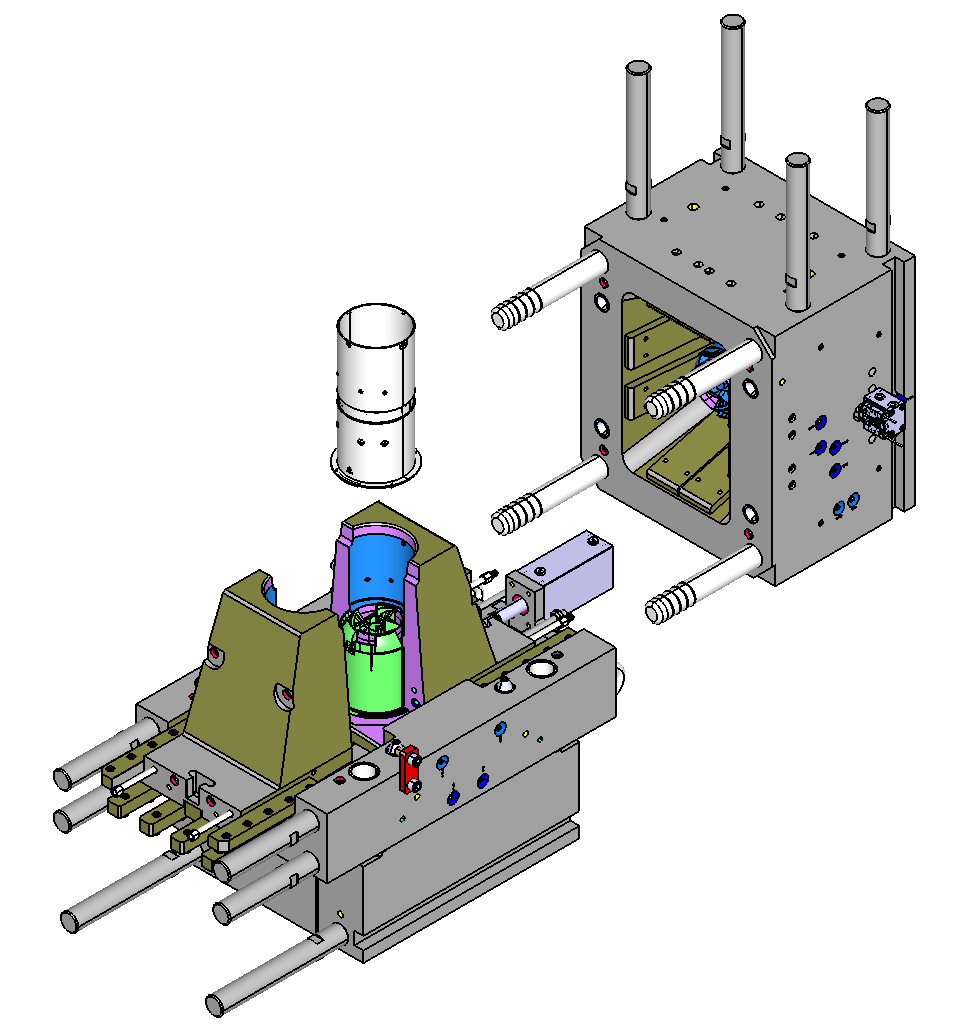

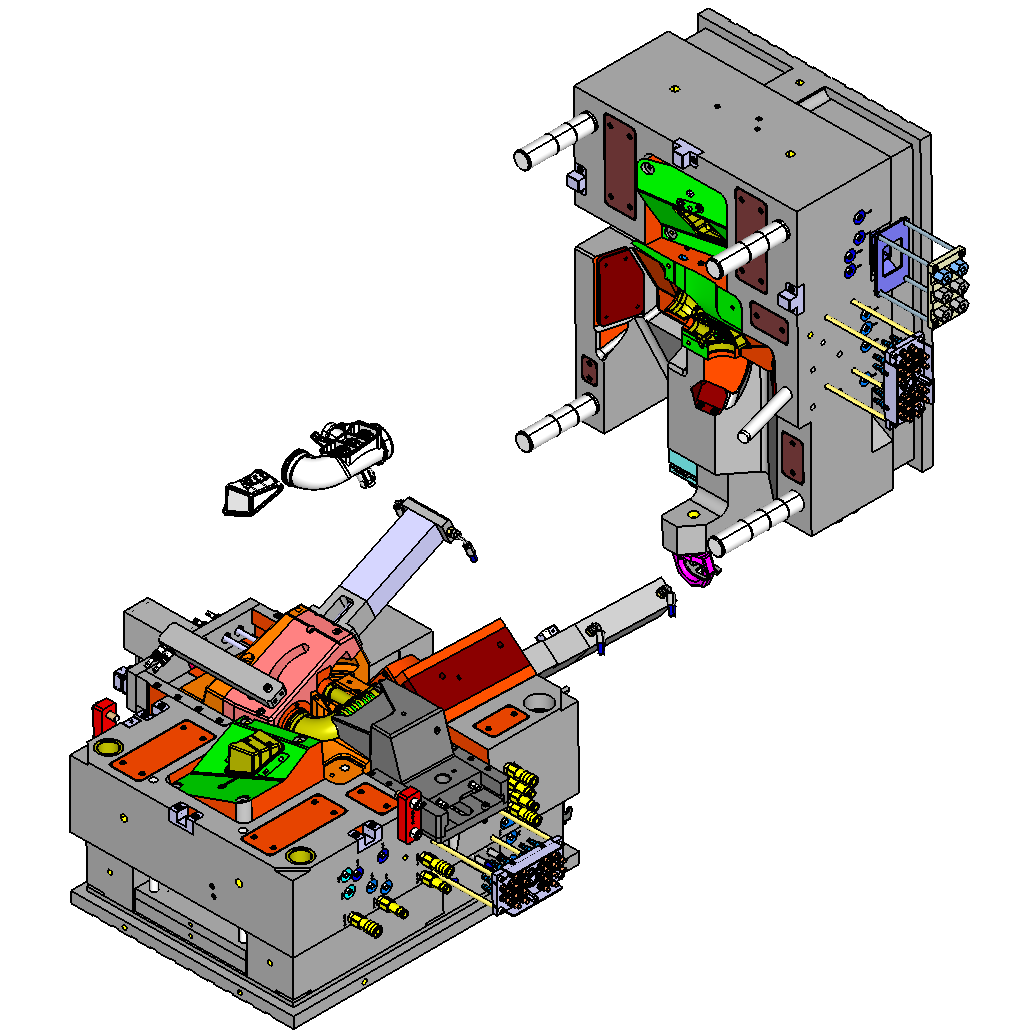

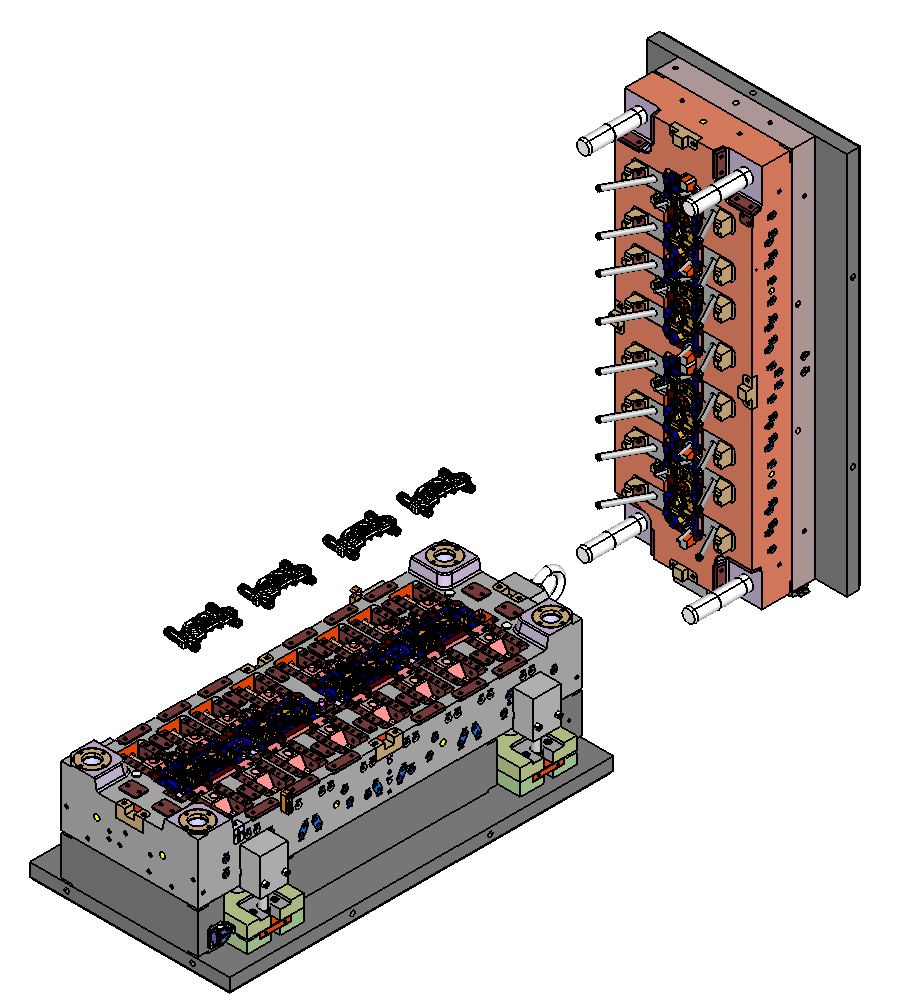

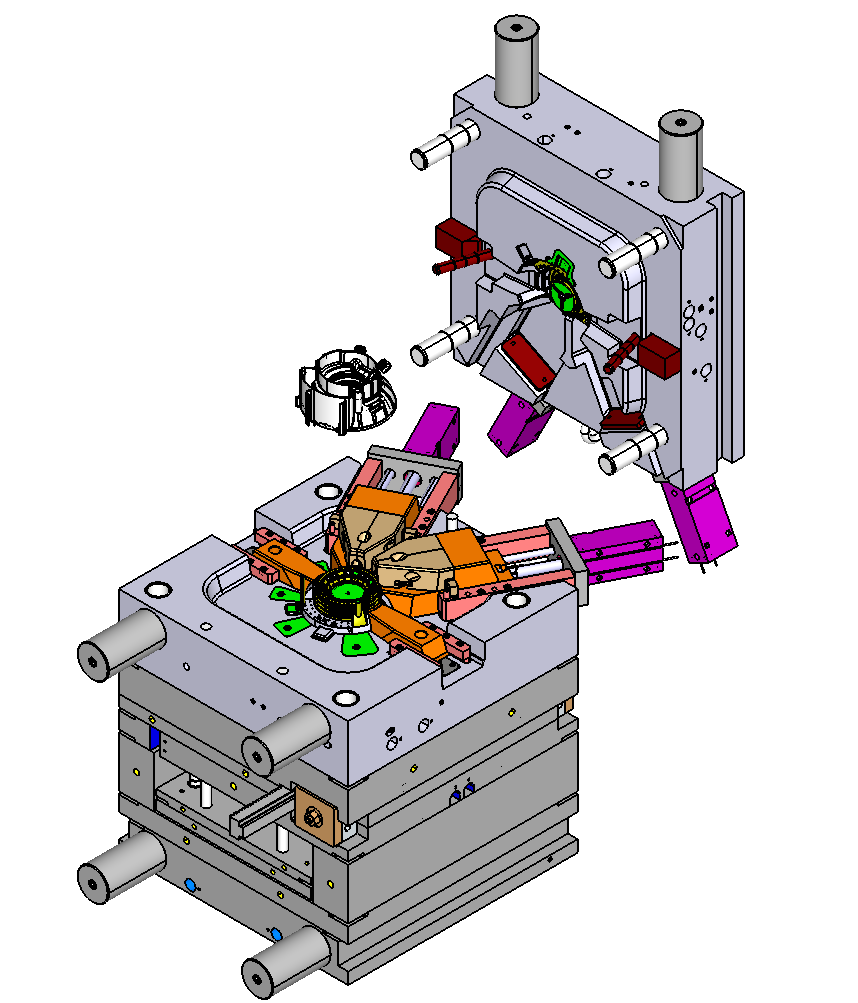

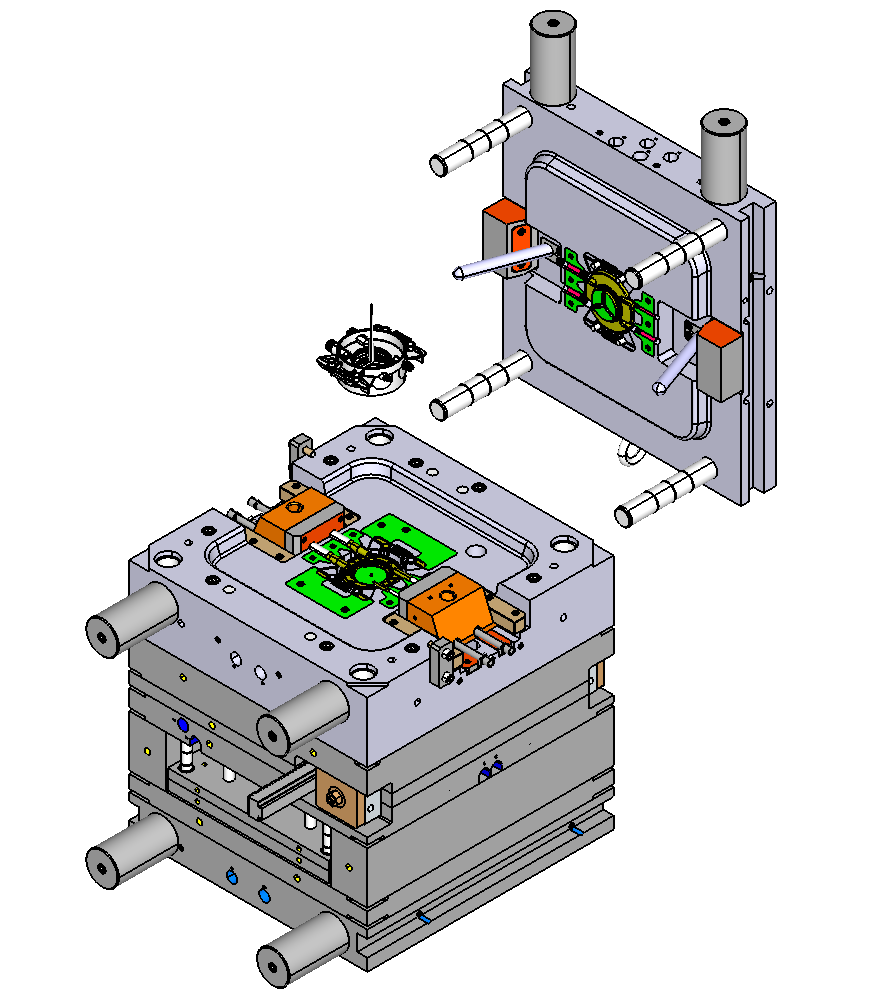

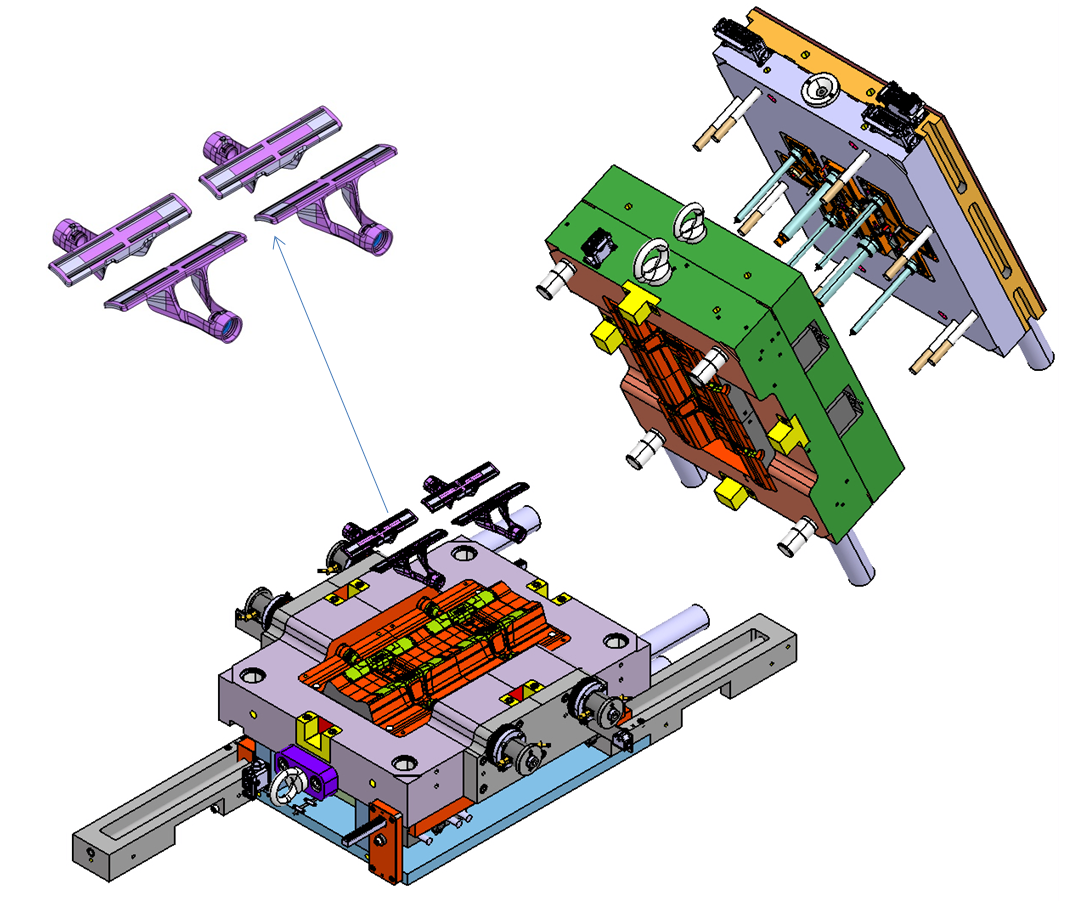

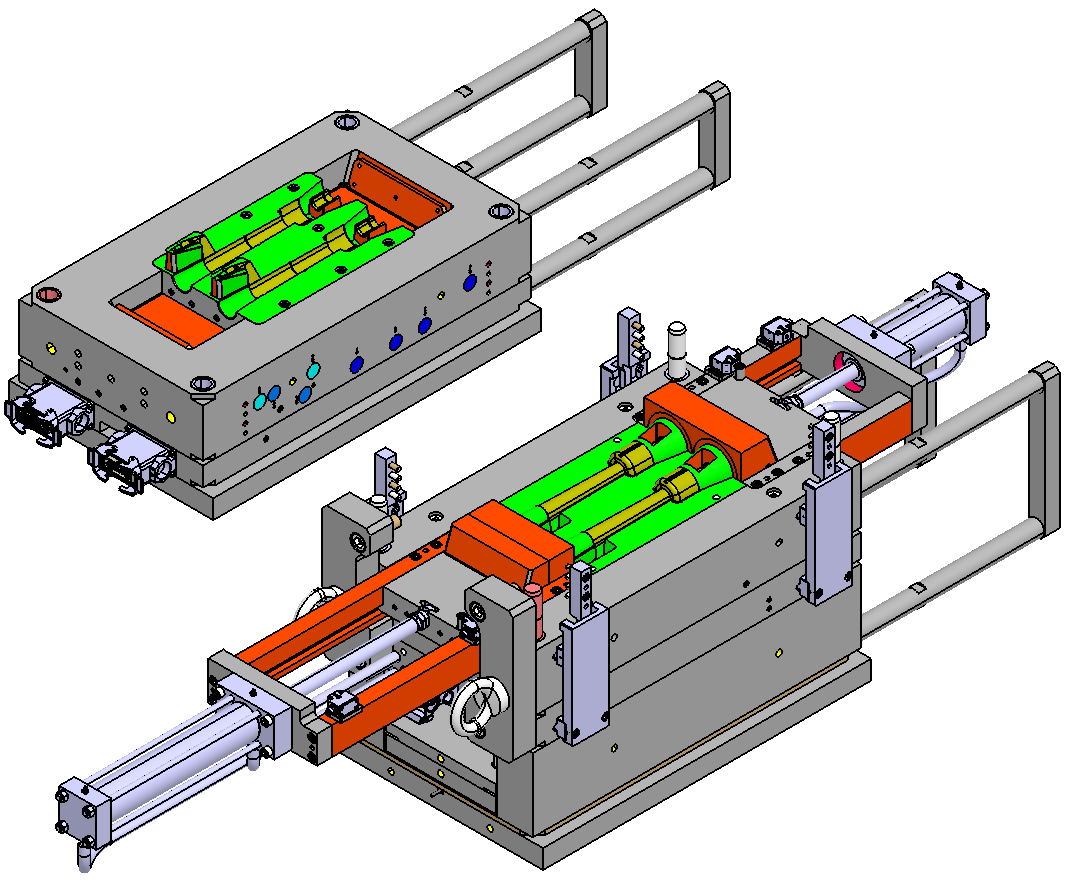

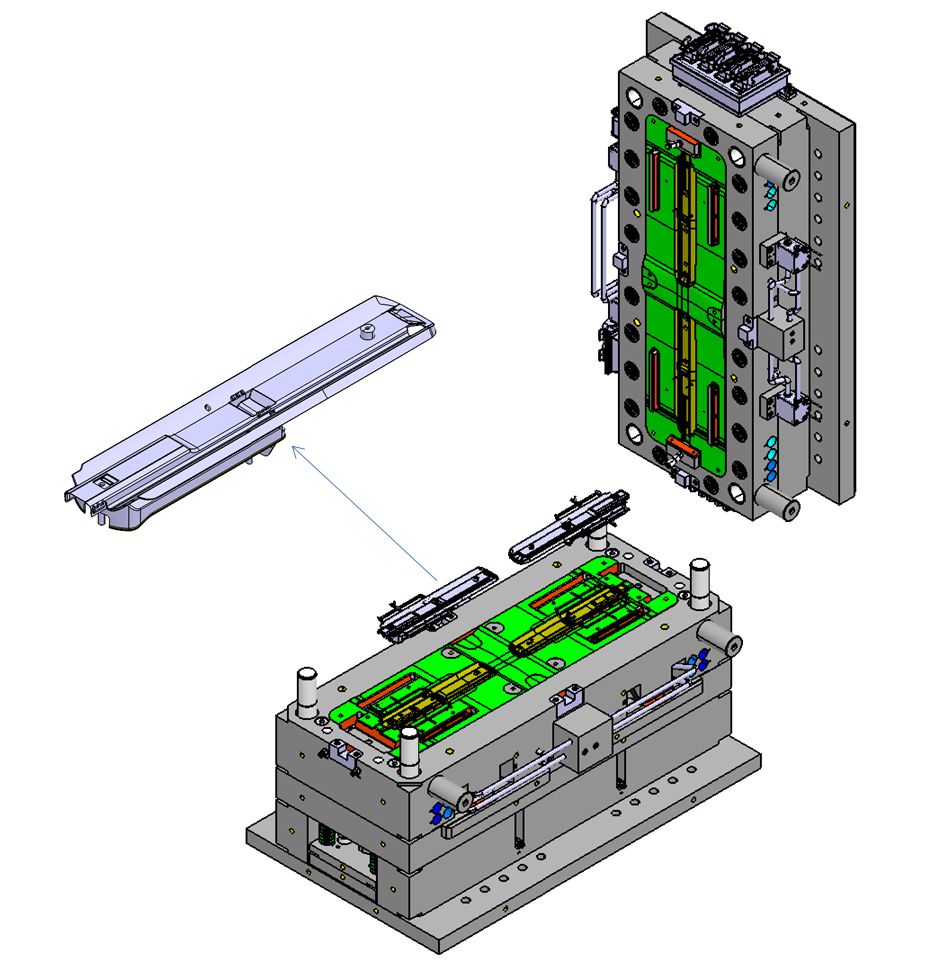

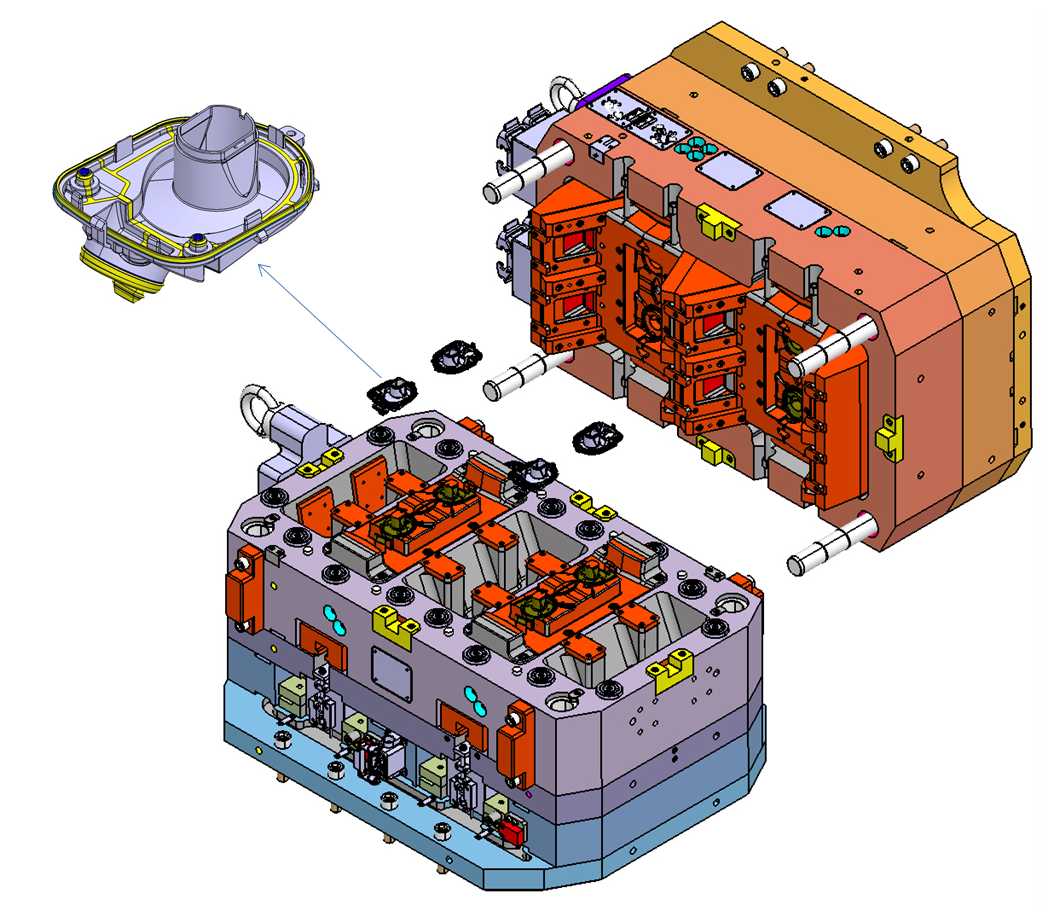

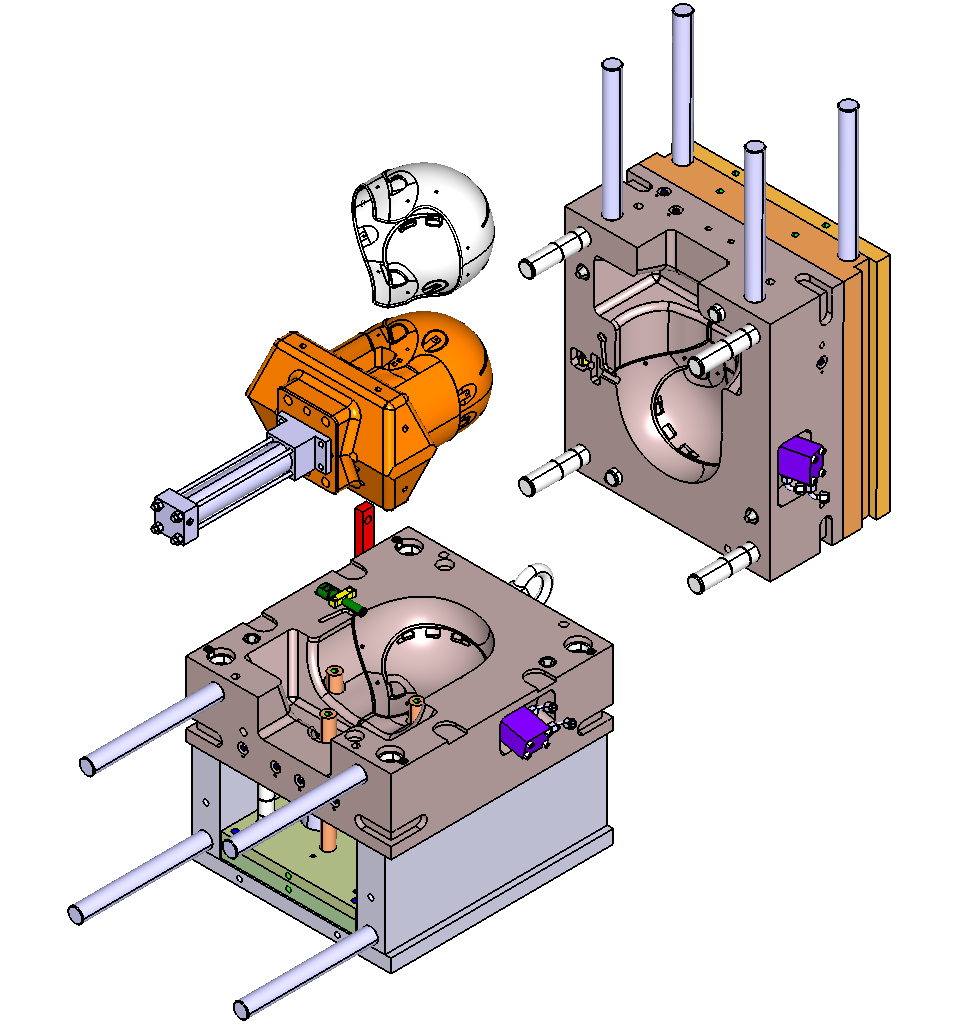

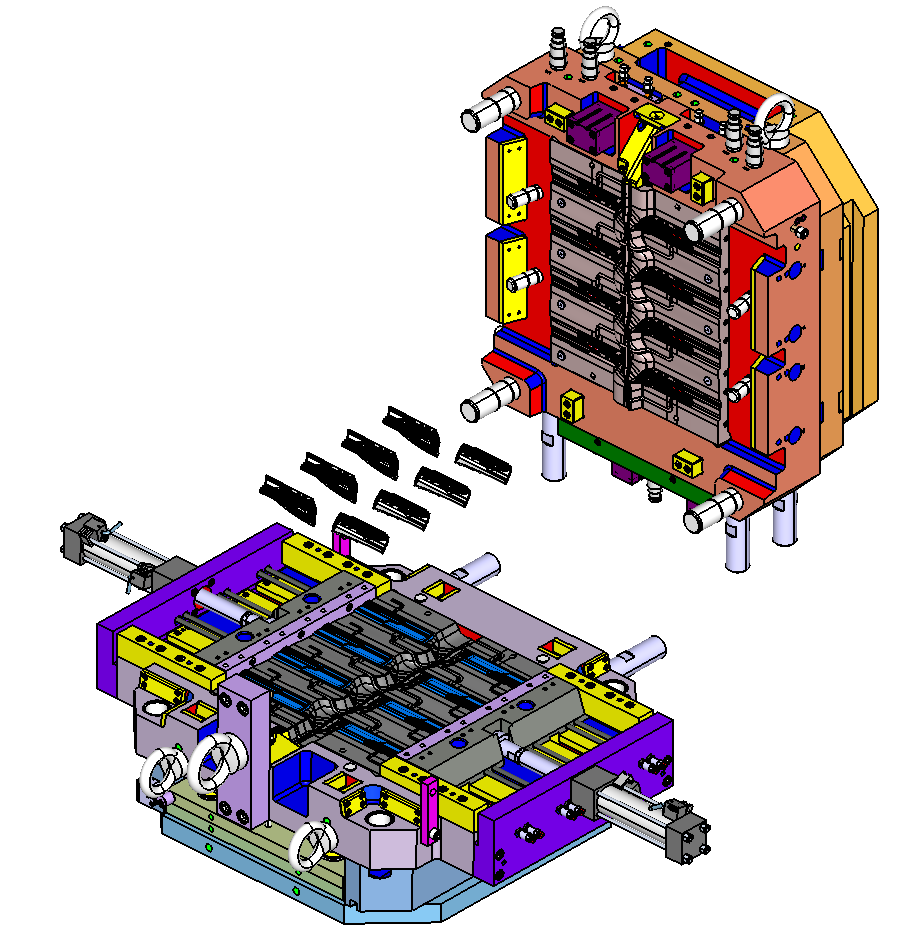

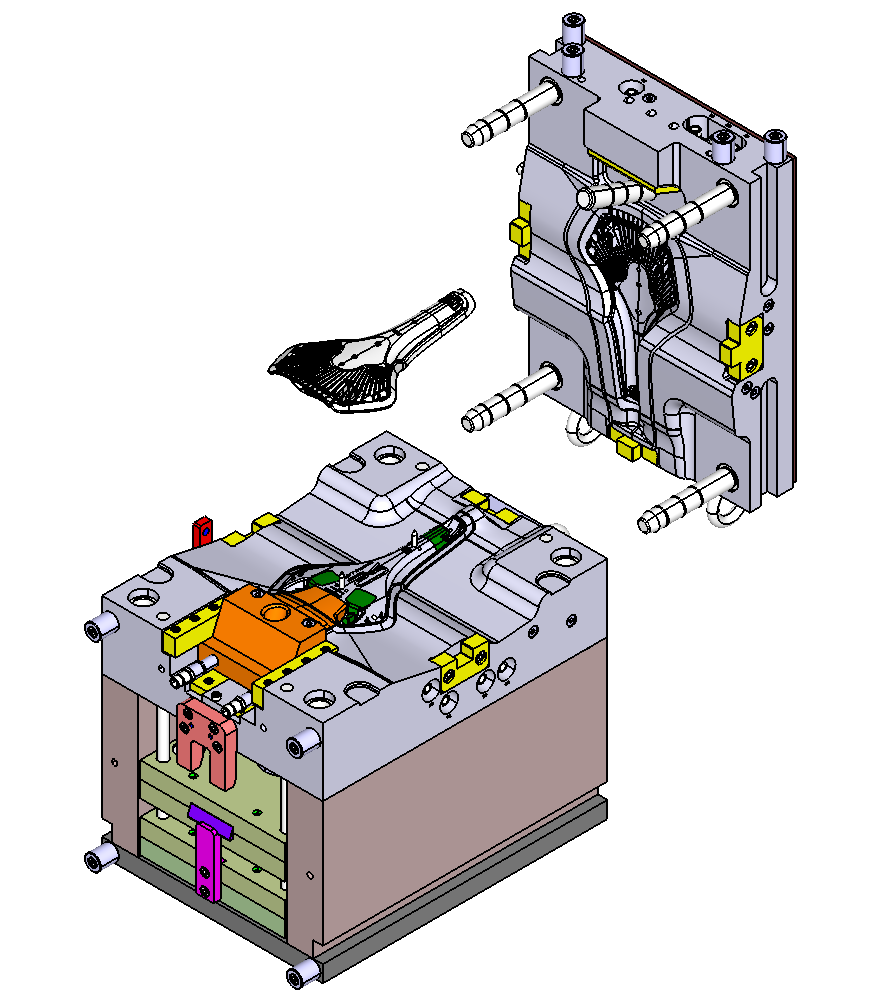

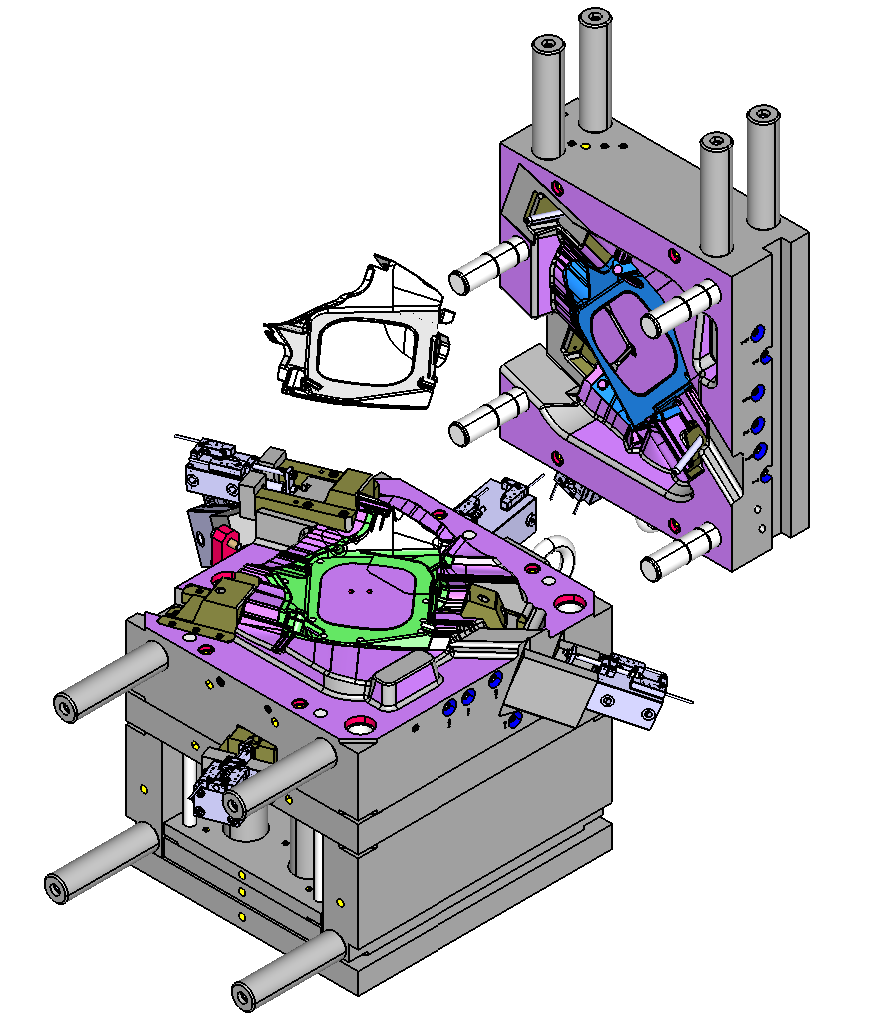

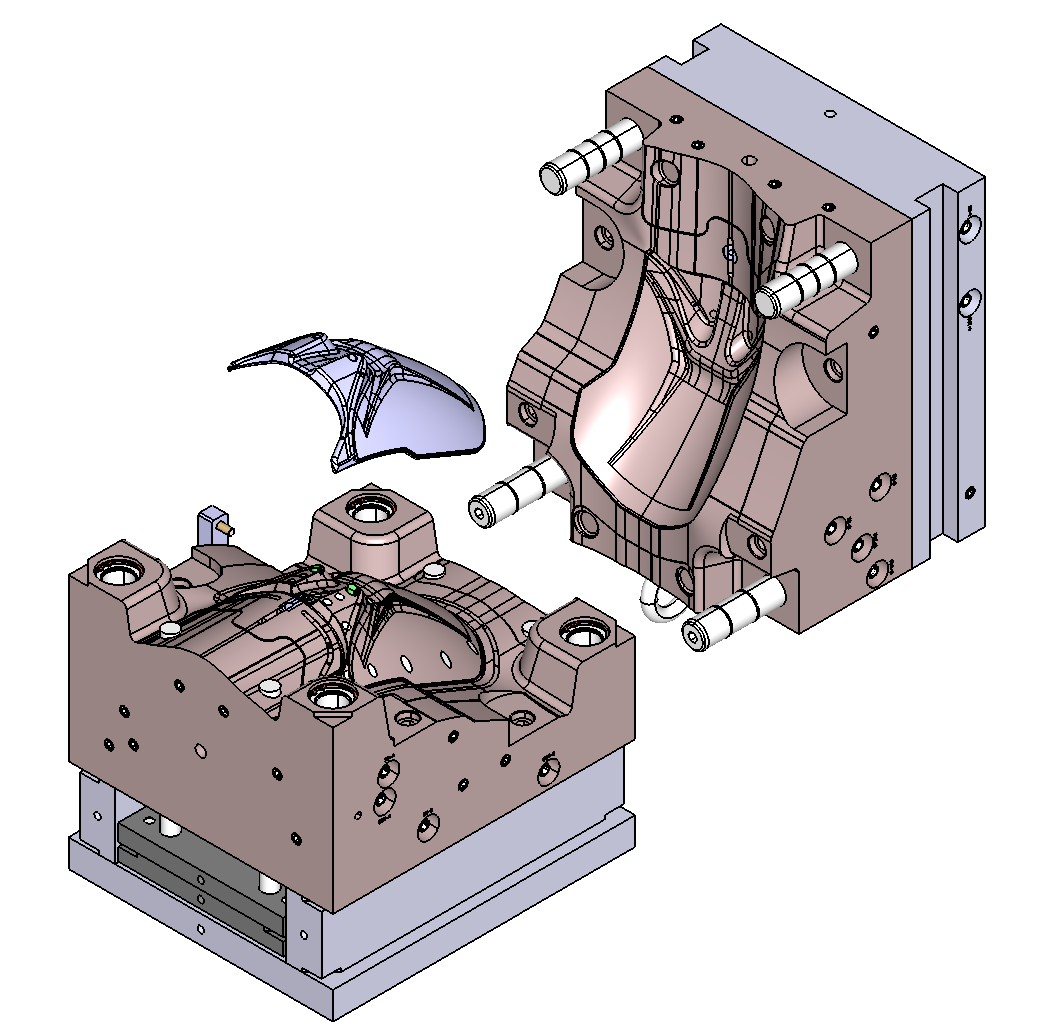

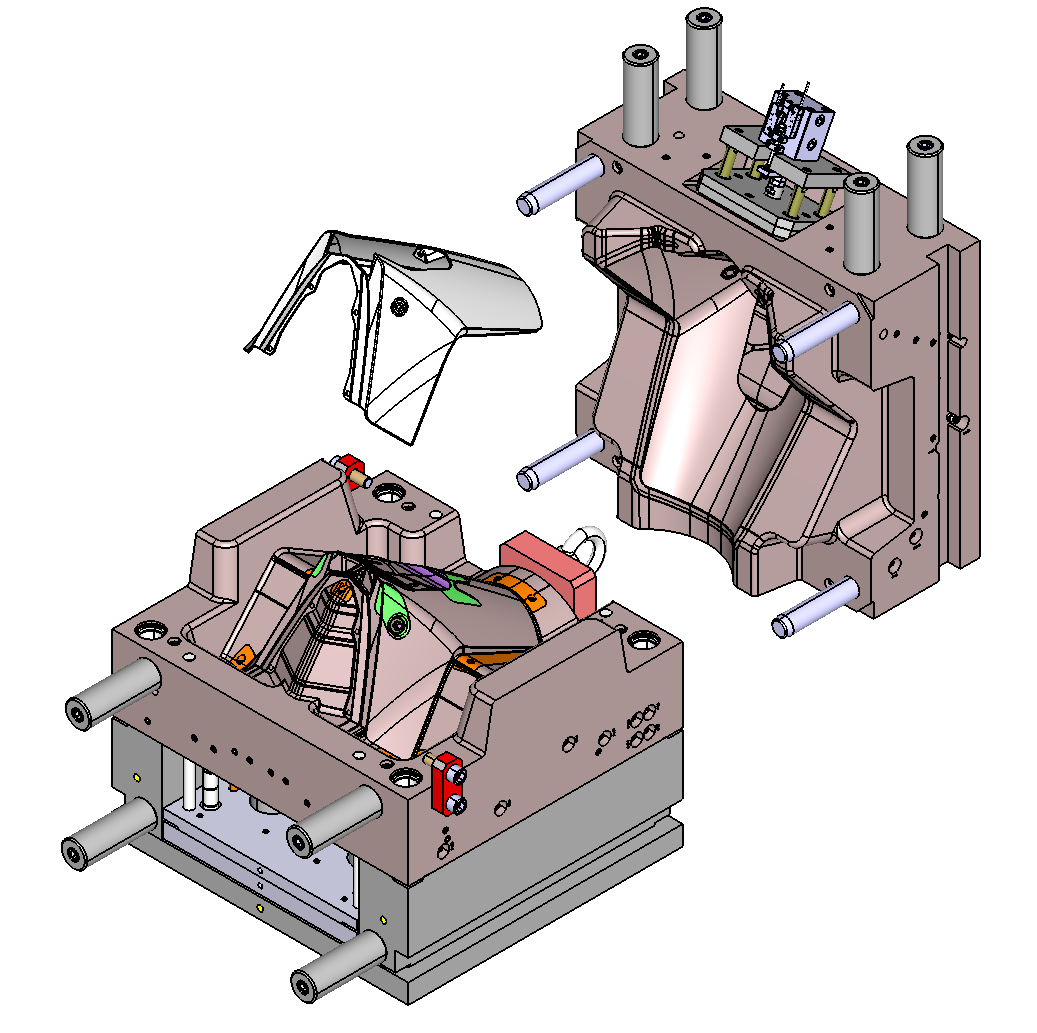

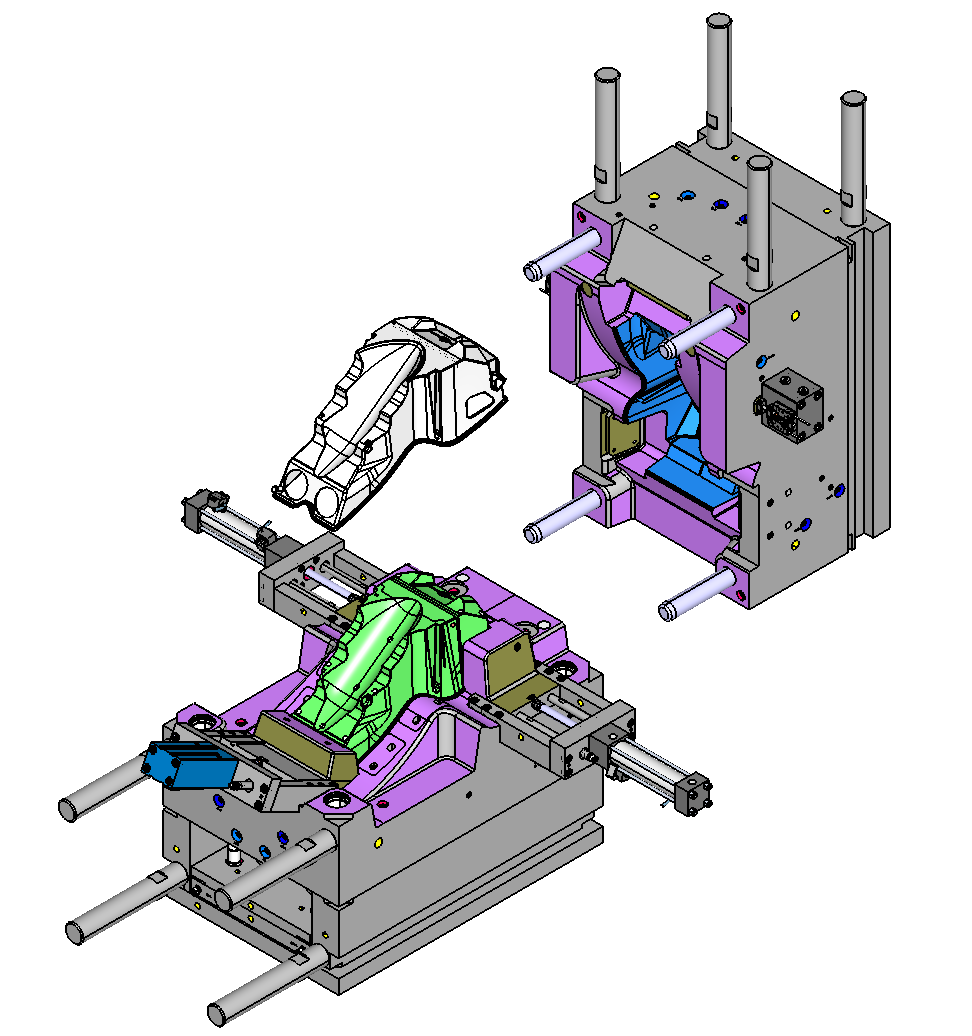

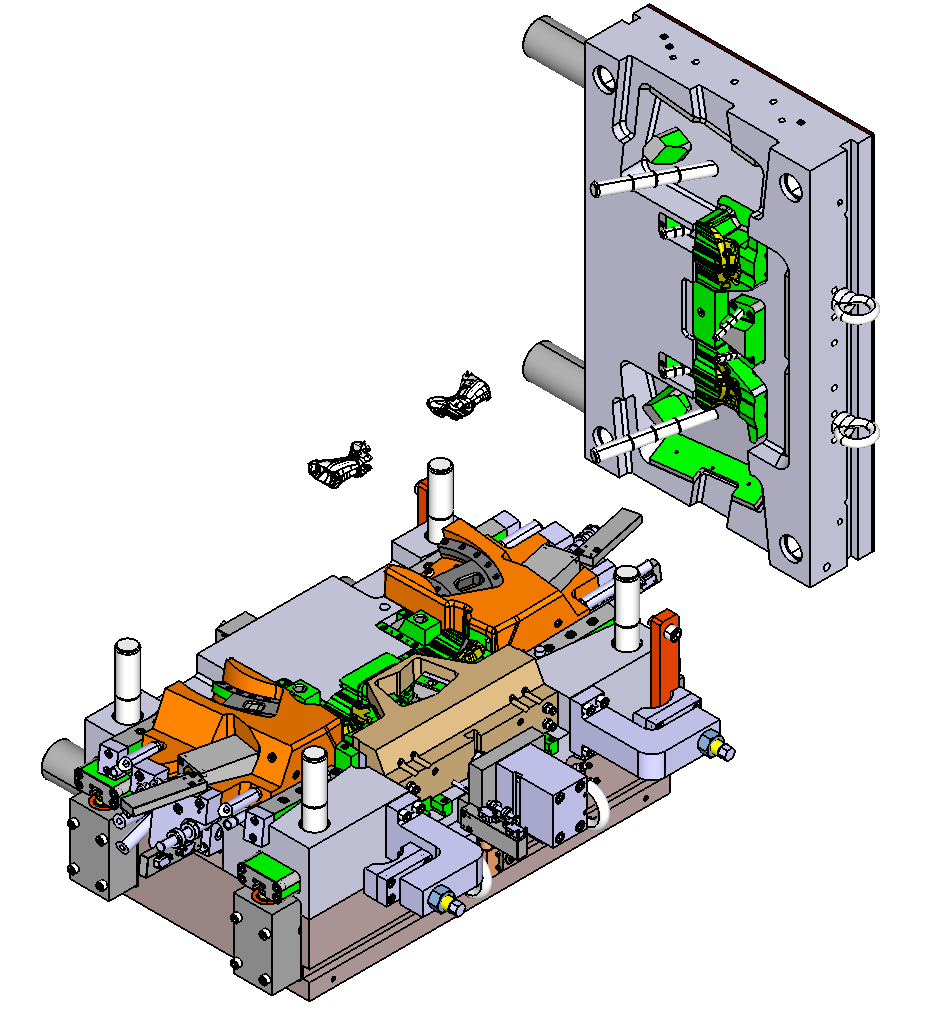

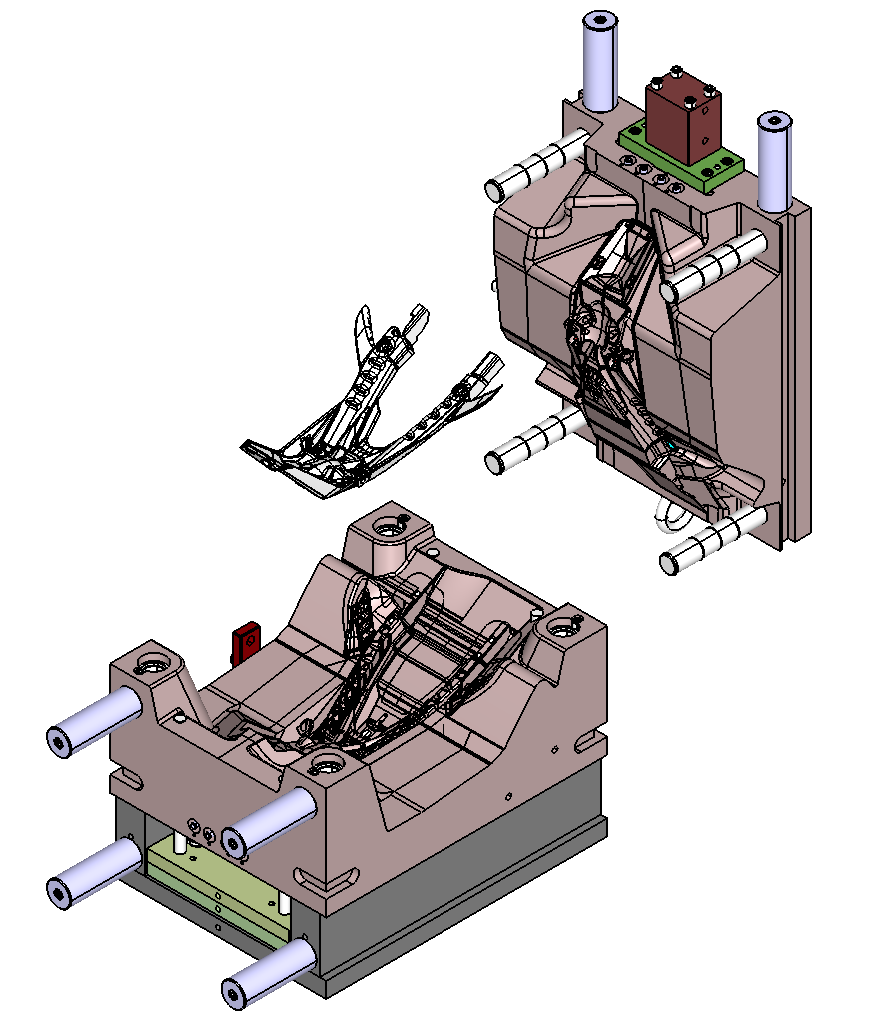

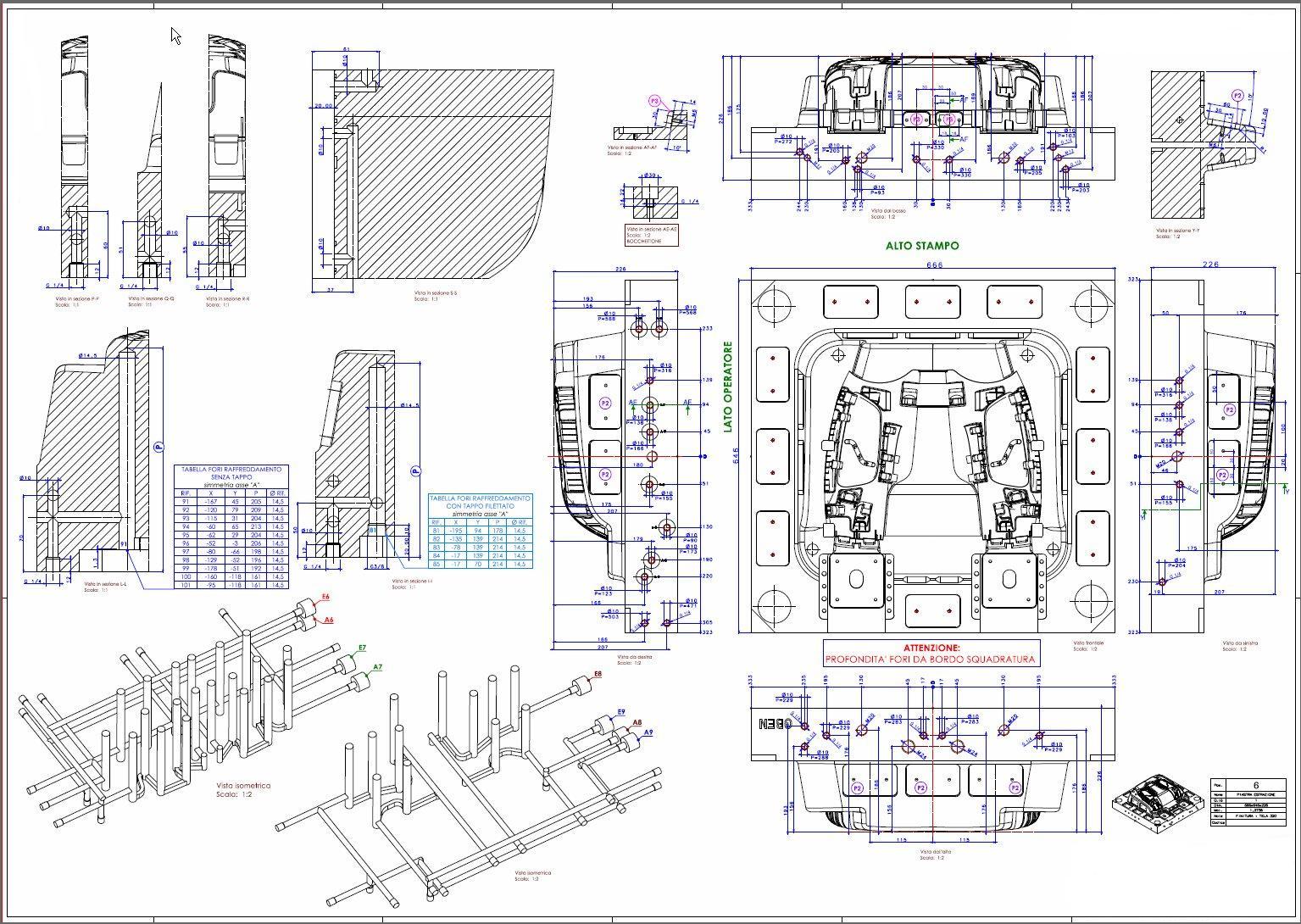

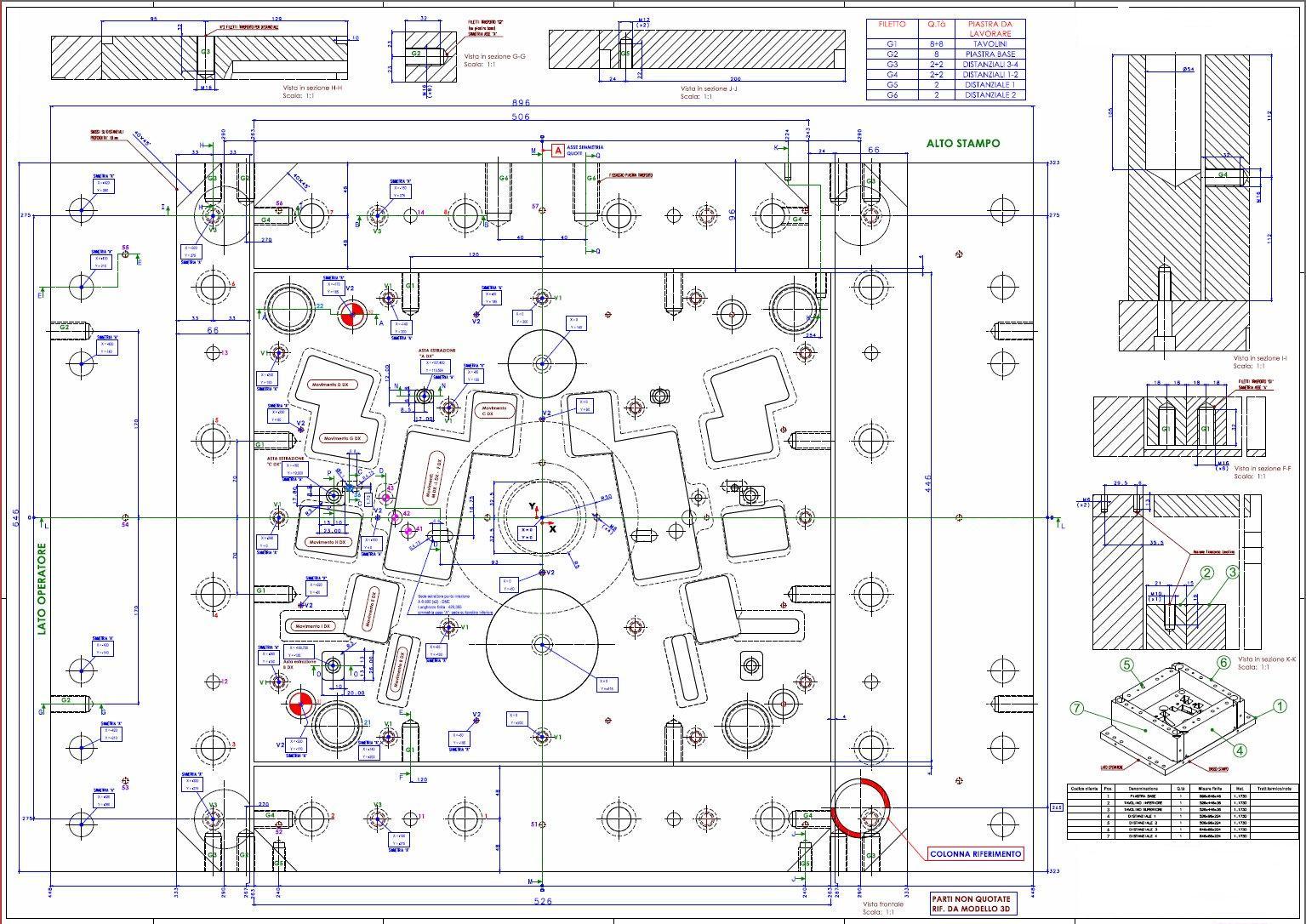

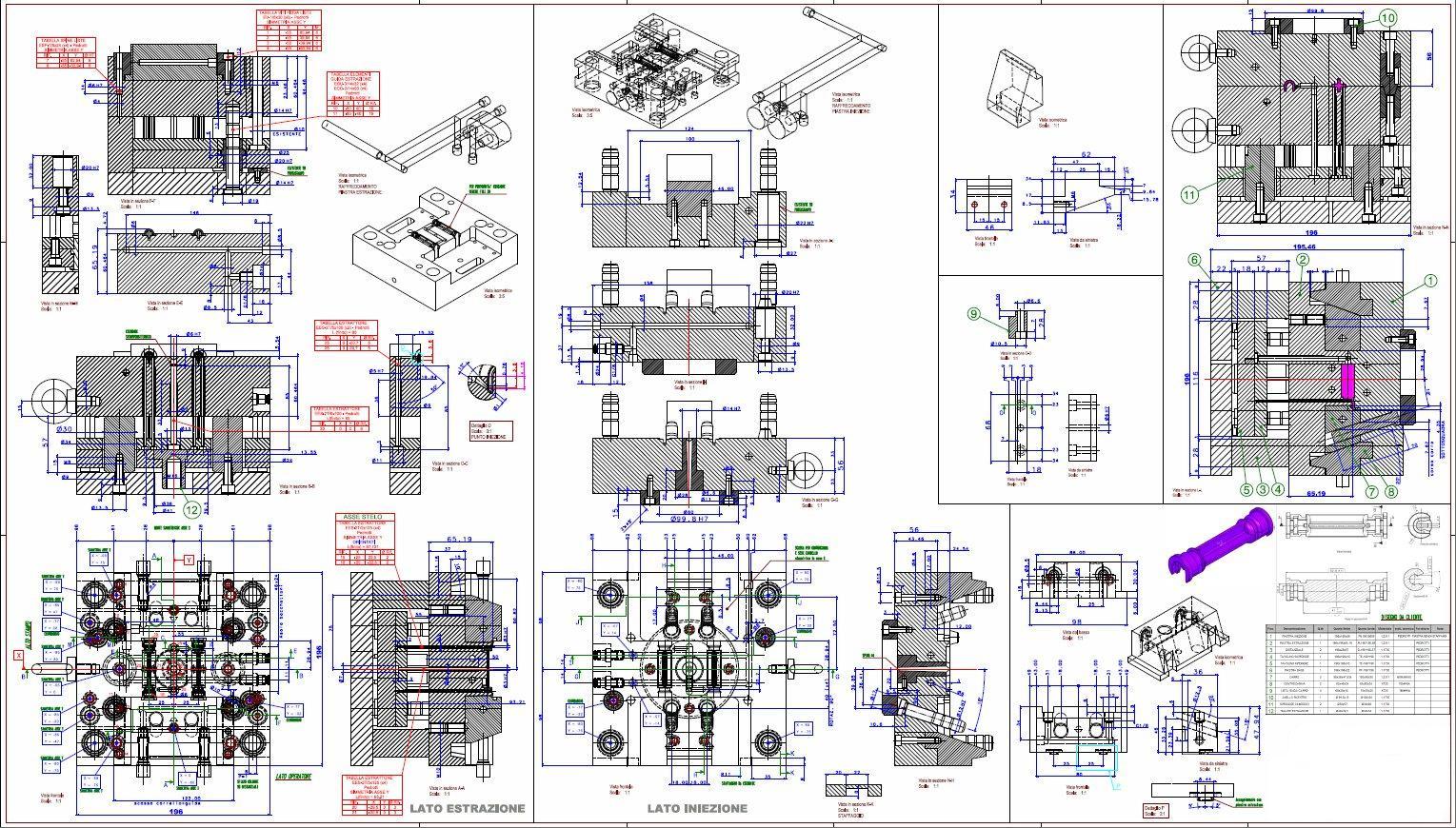

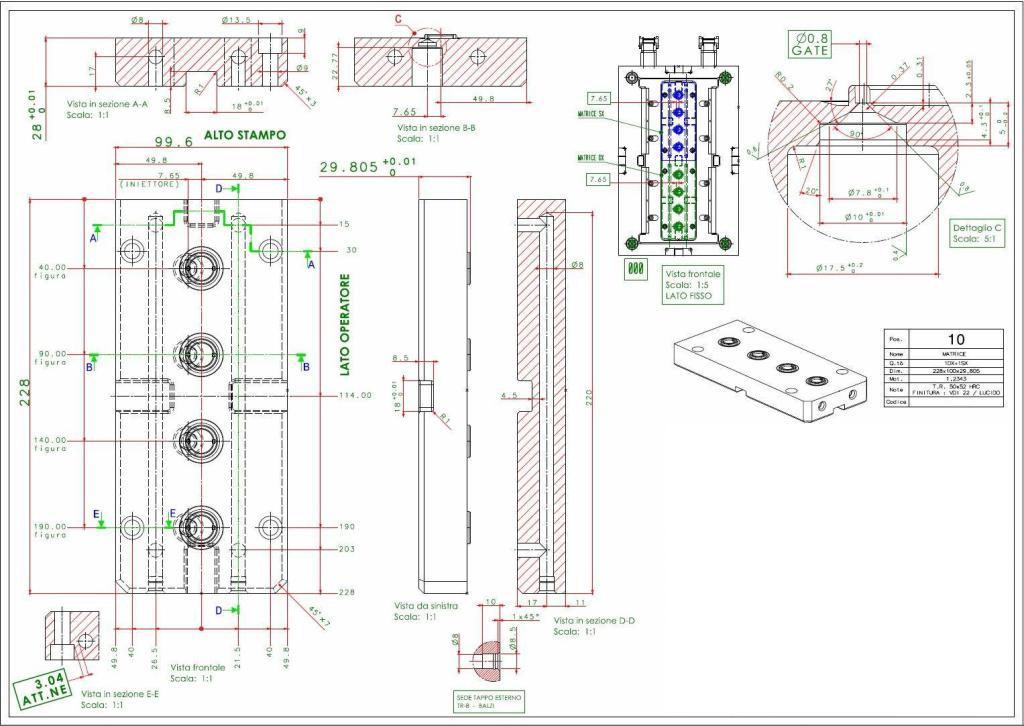

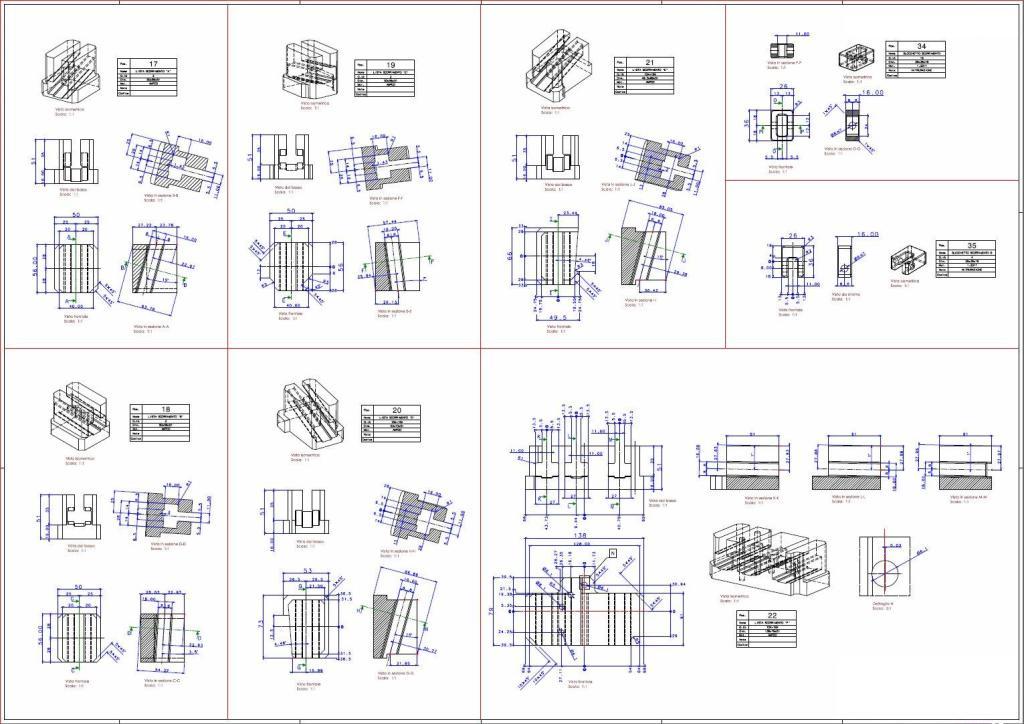

Step 3: 3D-Design

Design created in the smallest details considering all mechanical, functional and economic aspects.

We are fully equipped with cutting edge technology in order to offer you the best service in designing, testing and developping high quality products.

Starting from the concept to the engineering design process, from the prototyping to the drawing up of the constructive drawings we are able to satisfy all the production requirements obtaining significant advantages also in the moulding design process.

The tools offered by Catia help us quickly modify the moulding design, automatically updating the 2D tables.